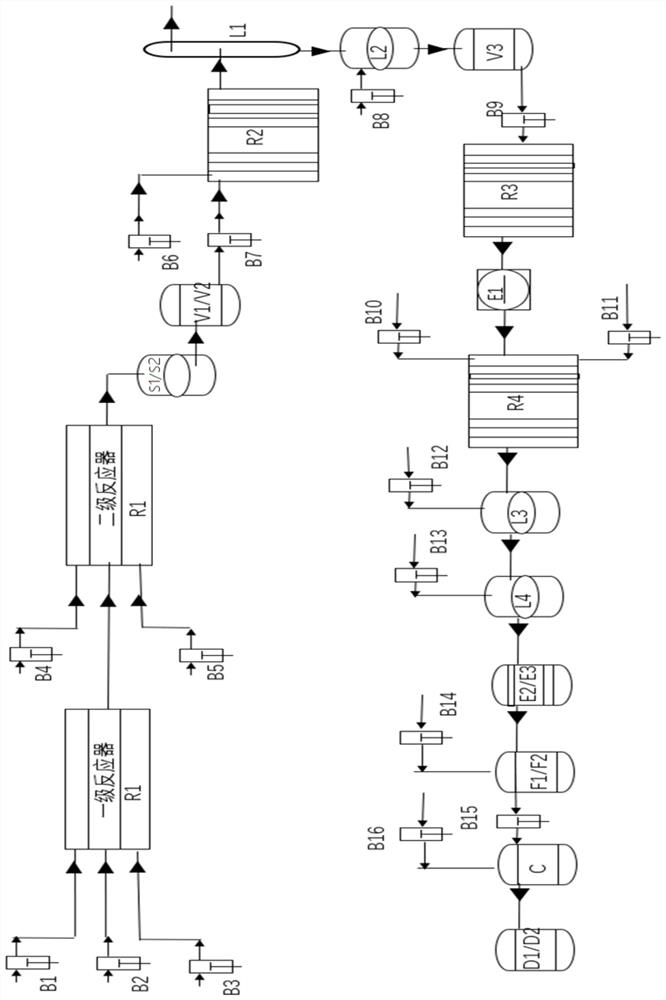

Continuous production method and device of meropenem side chain

A technology of meropenem side chains and production methods, which is applied in the field of continuous green synthesis of fine chemical products, and can solve the problem of excessive proportion of excipients in product quality, product yield and cost, inability to realize continuous production, heat and mass transfer Inefficiency and other problems can be achieved to reduce production safety risks, simplify post-processing processes, and improve heat and mass transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

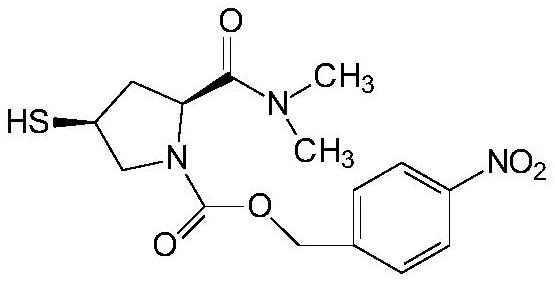

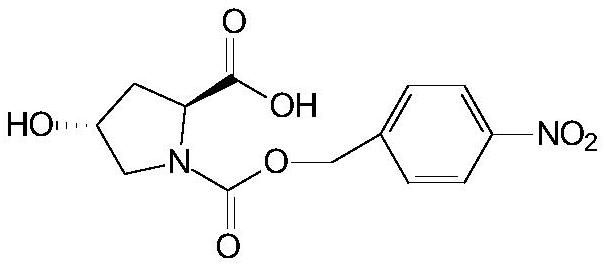

[0117] The acid binding agent in this embodiment adopts triethylamine, the activator adopts isopropyl chloroformate, the reducing agent adopts tri-n-butylphosphorus, and the crystallization organic solvent adopts ethyl acetate and n-hexane.

[0118] Dissolve 100.0Kg of O powder in 1300Kg of dichloromethane in advance, and cool it to 3 to 5°C to obtain solution A (dichloromethane solution of O powder), transfer it to a temporary storage tank of solution A, under nitrogen protection and heat preservation, wait until use;

[0119] Dissolve 200Kg of refined sodium chloride in 3800Kg of purified water, cool to 0~3°C to obtain solution B (5% brine), transfer it to a temporary storage tank of solution B, keep warm and wait for use;

[0120] Dissolve 100Kg of refined sodium chloride in 1520Kg of purified water, then add 380Kg of 35% refined hydrochloric acid, mix well, cool to 0 to 3°C to obtain solution C (acidic brine), transfer it to a temporary storage tank for solution C, keep wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com