Anti-beam-lowering bridge embedded board facilitating surface preservative treatment

An anti-corrosion treatment and technology for bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large occupied space, changing welding performance, complex structure, etc., and achieve the goals of improving operation efficiency, good surface hardness and anti-corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

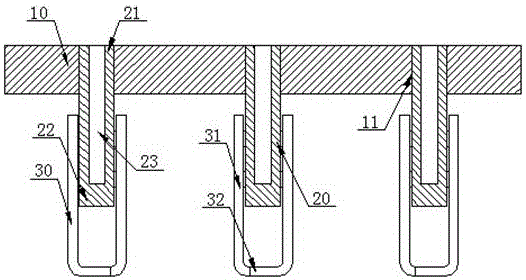

[0015] like figure 1 As shown, the anti-fall beam pre-embedded plate for bridges provided by this embodiment is convenient for surface anti-corrosion treatment, including a fixed plate 10, a pre-embedded cylinder body 20 and a pre-embedded steel bar 30, and the fixed plate 10 is provided with A number of installation through holes 11 for installing the embedded cylinder 20, the embedded cylinder 20 includes an installation end 21 and an embedded end 22, and the installation end 21 of the embedded cylinder 20 is provided with an installation screw hole 23 , the installation end 21 of the pre-embedded cylinder 20 is located in the installation through hole 11, the pre-embedded steel bar 30 includes a welded end 31 and a bent end 32, the welded end 31 of the pre-embedded steel bar 30 is connected to the The pre-embedded end 22 of the pre-embedded cylinder 20 is welded together; the inner wall of the installation through hole 11 is provided with an internal thread for installation...

specific Embodiment 2

[0017] A kind of pre-embedded plate for anti-falling beams for bridges that is convenient for surface anti-corrosion treatment provided in this embodiment, the specific structure is the same as that of the specific embodiment 1, and the difference from the specific embodiment 1 is: the fixed plate 10, the pre-embedded plate The surfaces of the buried cylinder 20 and the pre-embedded steel bar 30 are also provided with a Dacromet anti-corrosion coating, and the Dacromet anti-corrosion coating is located outside the multi-element alloy co-infiltration anti-corrosion coating, and the Dacromet anti-corrosion coating A sealing layer is also arranged outside; the raw materials of the dacromet anti-corrosion coating are chromate, zinc flakes and aluminum flakes; the raw materials of the sealing layer are epoxy resin containing zinc foil or aluminum foil.

[0018] When processing the pre-embedded plate for anti-fall beams of bridges that are convenient for carrying out surface anti-cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com