Adjusting device of mixed flow water turbine

A technology of adjusting device and water turbine, which is applied in the direction of fluid pressure actuating device, safety device, engine sealing, etc., can solve the problems of shortening the maintenance time of the relay, difficult control of movable guide vanes, low reliability, etc., and achieves a small occupied space. , The effect of small radial displacement and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

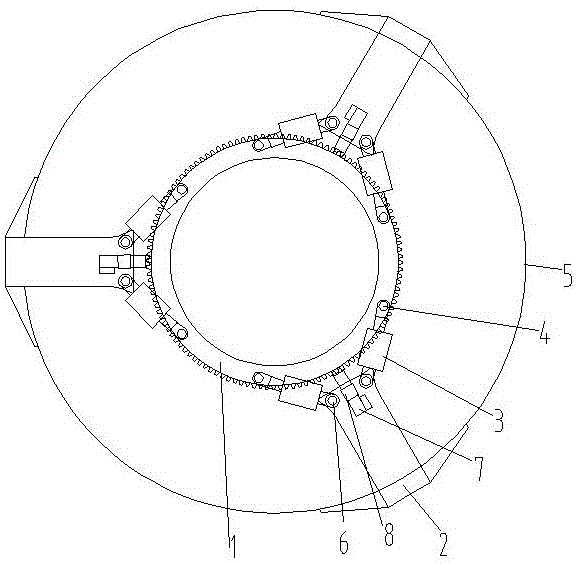

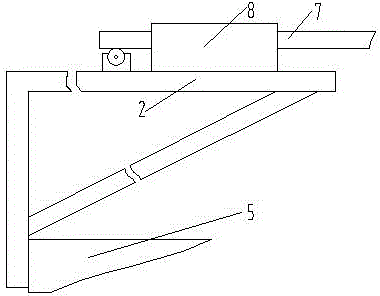

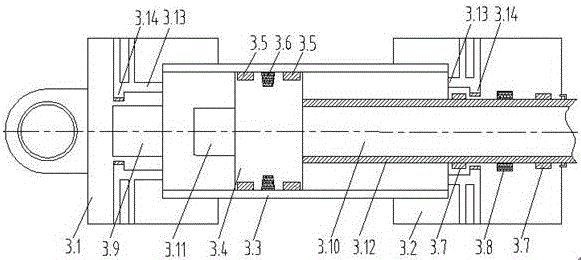

[0033] Such as figure 1 , figure 2 and image 3 The adjustment device of the Francis turbine shown includes control ring 1, support base 2, servomotor 3, A cylinder head 3.1, B cylinder head 3.2, cylinder barrel 3.3, piston 3.4, guide ring 3.5, trapezoidal seal groove 3.6, guide Groove 3.7, sealing groove 3.8, buffer groove 3.9, piston rod 3.10, buffer head 3.11, sleeve 3.12, through hole 3.13, sedimentation tank 3.14, fixed rod 4, top cover 5, support rod 6 and limit rod 7, for The control ring 1 that controls the opening of the movable guide vane is installed on the top cover 5 of the water turbine, and three support seats 2 are equidistantly installed on the outer wall of the top cover 5, and each support seat 2 is symmetrically provided with two vertical support rods 6. There are six uniformly distributed fixed rods 4 on the top surface of the control ring 1, and the two ends of the servomotor 3 are respectively connected to the fixed rods 4 and the support rods 6 by ro...

Embodiment 2

[0037] Such as figure 1 , figure 2 and Figure 4 The adjustment device of the Francis turbine shown includes control ring 1, support base 2, servomotor 3, A cylinder head 3.1, B cylinder head 3.2, cylinder barrel 3.3, piston 3.4, guide ring 3.5, trapezoidal seal groove 3.6, guide Groove 3.7, sealing groove 3.8, buffer groove 3.9, piston rod 3.10, buffer head 3.11, sleeve 3.12, through hole 3.13, sedimentation tank 3.14, fixed rod 4, top cover 5, support rod 6 and limit rod 7, for The control ring 1 that controls the opening of the movable guide vane is installed on the top cover 5 of the water turbine, and three support seats 2 are equidistantly installed on the outer wall of the top cover 5, and each support seat 2 is symmetrically provided with two vertical support rods 6. There are six uniformly distributed fixed rods 4 on the top surface of the control ring 1, and the two ends of the servomotor 3 are respectively connected to the fixed rods 4 and the support rods 6 by r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap