A kind of liquid ice precooling device for agricultural products

A technology of liquid ice and agricultural products, which is applied to household refrigeration devices, ice making, ice making, etc., can solve the problems of inability to form automation and mechanical operation, and no guarantee of pre-cooling, so as to save pre-cooling time, reduce water consumption, The effect of fast pre-cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0057] The above-mentioned liquid ice tank 1 and the above-mentioned liquid ice making unit do not share the same side wall, that is, the two are separated, and the flow channel of cold water is formed through the pipeline.

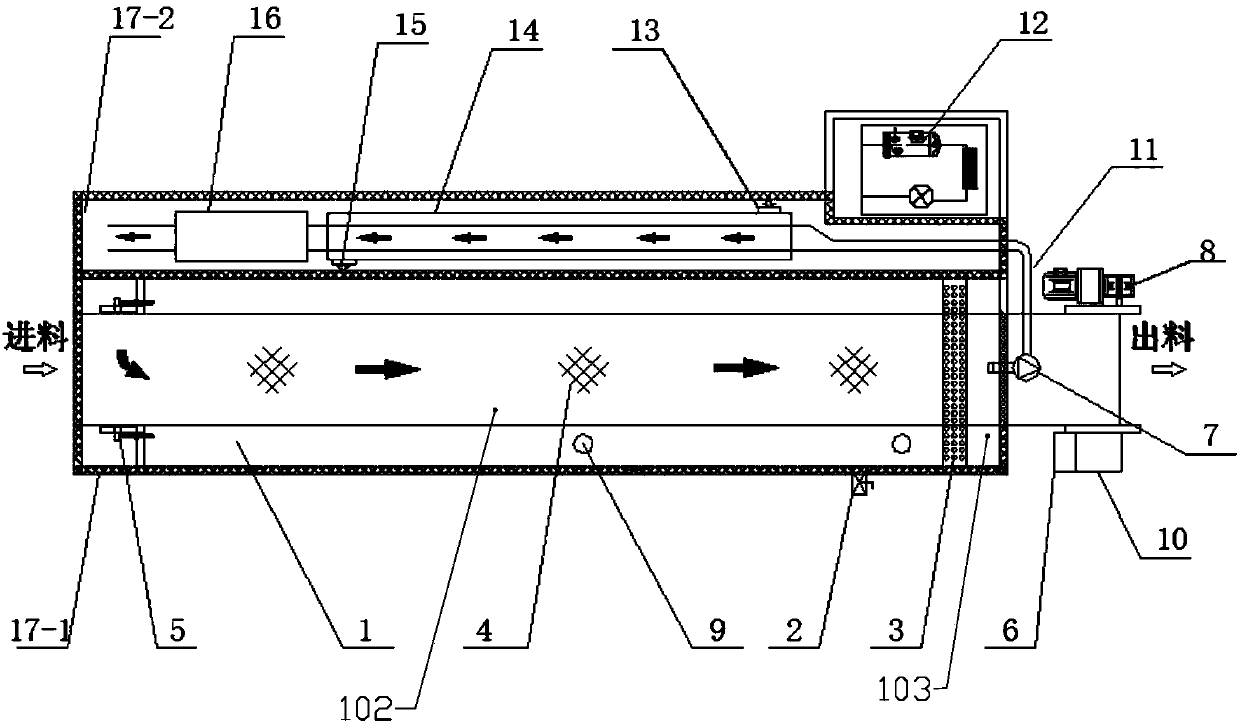

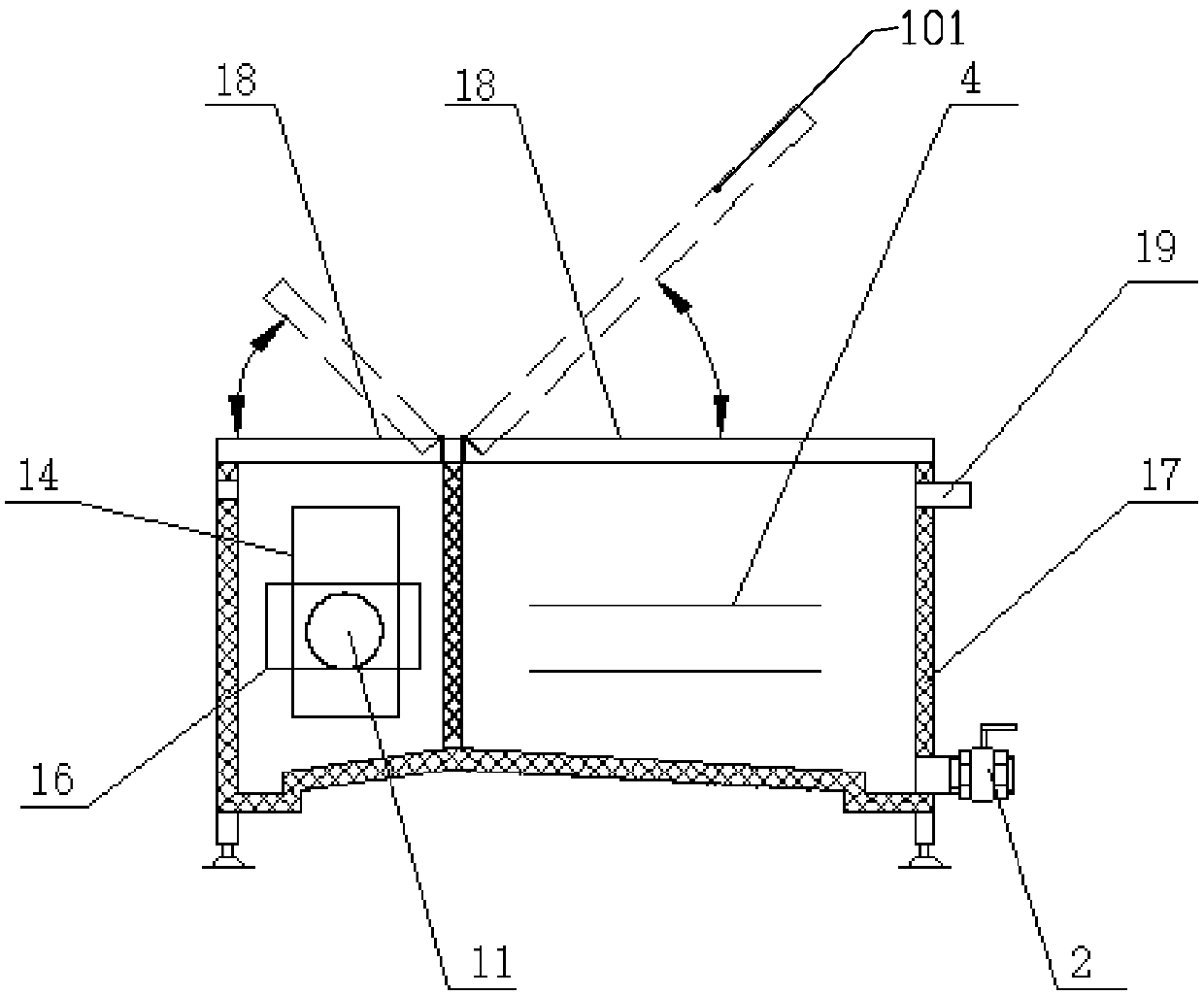

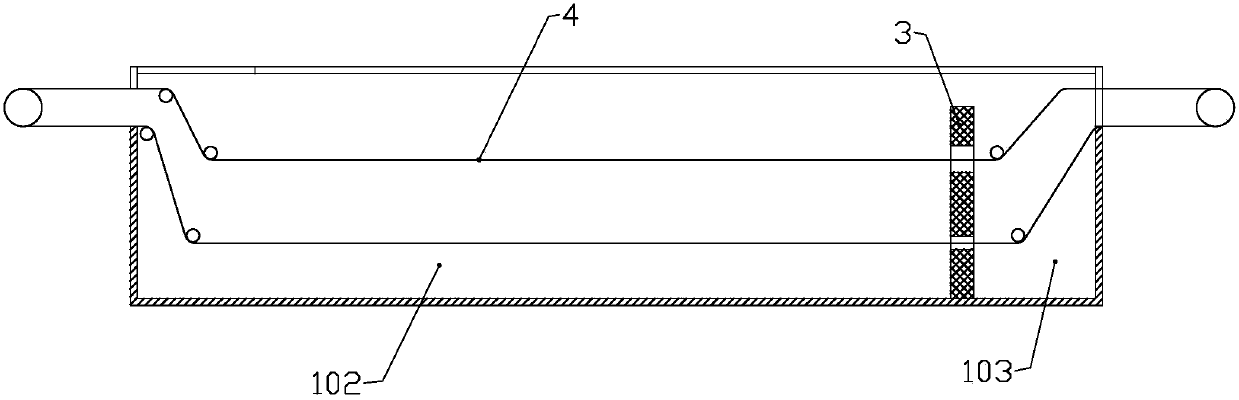

[0058] The food is pre-cooled in the liquid ice tank 1, and there is a conveyor belt 4 in the liquid ice tank, and the conveyor belt is equipped with a frequency conversion controller 6 and a gear motor for speed regulation. Normal water, the water is filtered and purified by the filter device 3, and then enters the subcooler 14 through the circulation pipeline 11 through the circulating water pump to exchange heat with the refrigerant and is cooled to a supercooled state. The supercooled state refers to subcooling below the freezing point temperature. stable liquid state. The supercooled water is transported to the decooler 16 (ultrasonic generation tank can also be used), and decooled, and turns into tiny ice crystals, and the ice-water mixture in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com