Novel composite honeycomb board

A honeycomb composite panel, a new type of technology, applied in the direction of synthetic resin layered products, building components, coatings, etc., can solve the problems of increasing the self-weight of honeycomb panels, good sound insulation and heat insulation, poor flammable and fireproof performance, etc., to improve sound insulation. Heat insulation, improve strength and rigidity, good effect of fatigue fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

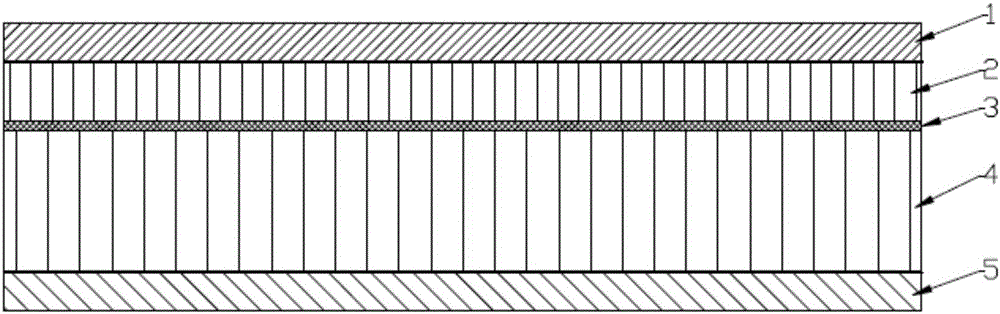

[0019] Such as figure 1 As shown, the present invention provides a new type of honeycomb composite panel, which is light in weight, high in strength, good in fire resistance and has excellent energy-saving and heat-preserving effects. , the second composite honeycomb core layer 4, the back plate 5; the above-mentioned 5-layer structural layer and the layer are bonded by a two-component polyurethane adhesive; the first composite honeycomb core layer 2 and the second honeycomb core layer 4 It is formed by bonding several hexagonal honeycomb cells integrally formed by aviation resin-based composite materials; the size of the honeycomb cells of the first composite honeycomb core layer 2 is smaller than that of the second composite honeycom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com