PET embossed release film for rubber isolation

A release film and embossing technology, which is applied in the field of release film to isolate rubber semi-finished products, can solve the problems of rubber injection molding, large heat shrinkage deformation rate, and large surface tension, so as to reduce energy consumption and pollution, and reduce production Low cost and good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

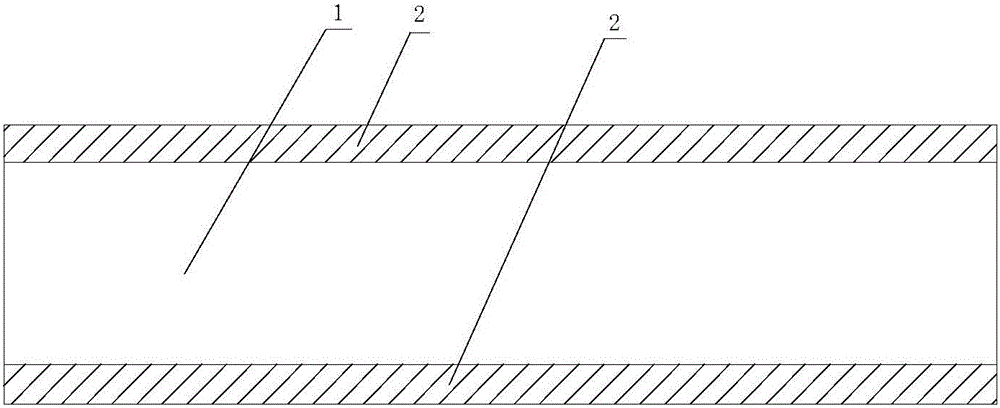

[0011] Example 1 as figure 1 As shown, the PET layer 1 is made of a PET film with a thickness of 250 μm, and the PE coating layer 2 is arranged on the upper and lower surfaces of the PET layer. The thickness of each layer of the PE coating layer 2 is 0.038±0.008mm. The surface of layer 2 is provided with a grid-like embossed pattern, of course, the embossed pattern can also be in other shapes, and this does not limit the present invention. This is a single-layer PET embossed release film for rubber isolation. .

Embodiment 2

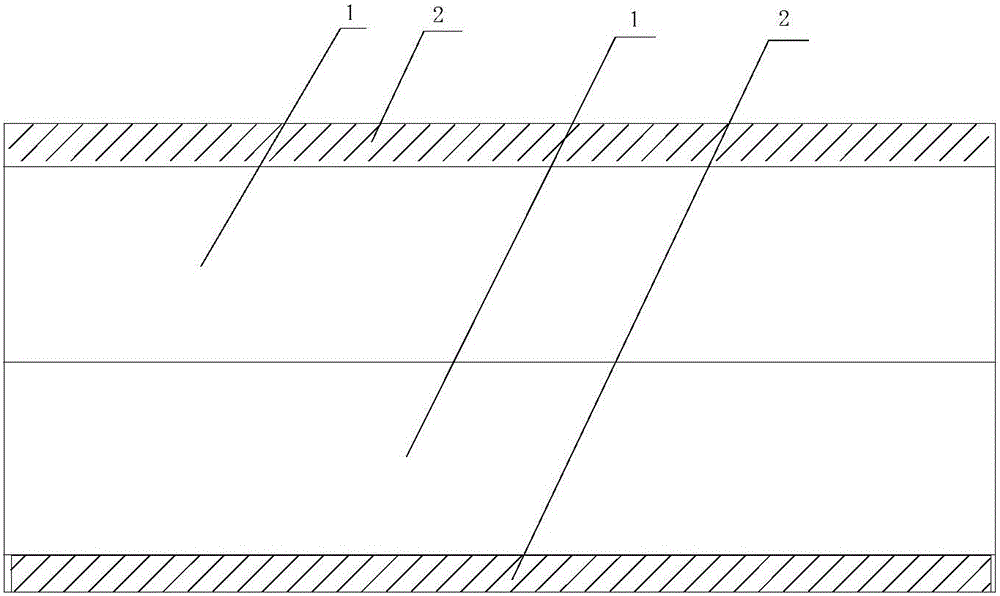

[0012] Example 2 as figure 2 As shown, a PET film with a thickness of 100 μm is used to make two PET layers 1, and one of the surfaces of each PET layer 1 is provided with a PE coating layer 2, and the thickness of each PE coating layer 2 is 0.038±0.008mm. Set a grid-like embossed pattern on the surface of the PE coating layer 2, and then compound the two PET layers with PET composite glue. When compounding, keep the PE coating layer 2 respectively located on the upper and lower outer surfaces of the release film. , This structure is a double-layer PET embossed release film for rubber isolation.

Embodiment 3

[0013] The structure of embodiment 3 is basically the same as that of embodiment 2, the difference is that a layer of PET is added between the PET layers to increase the overall strength and toughness of the release film.

[0014] The PET embossed release film for rubber isolation of the present invention adopts the structure of setting a PE coating layer on the PET, which increases the impact strength of the release film, is not easy to tear, and has a small thermal shrinkage deformation rate, so it can be used repeatedly. And the PE coating has good corrosion resistance characteristics, and the embossed texture is set on the PE coating, which can keep the surface of the release film and the rubber surface with good air permeability and easy to peel off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com