Method for producing concentrated nitric acid storage tank by winding carbon fibers

A concentrated nitric acid, carbon fiber technology, applied in packaging, large containers, transportation and packaging, etc., can solve the problems of self-weight, reduce the weight of the tank, and it is difficult to meet the requirements of railway transportation, and achieve the optimal winding angle and prevent galvanic corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

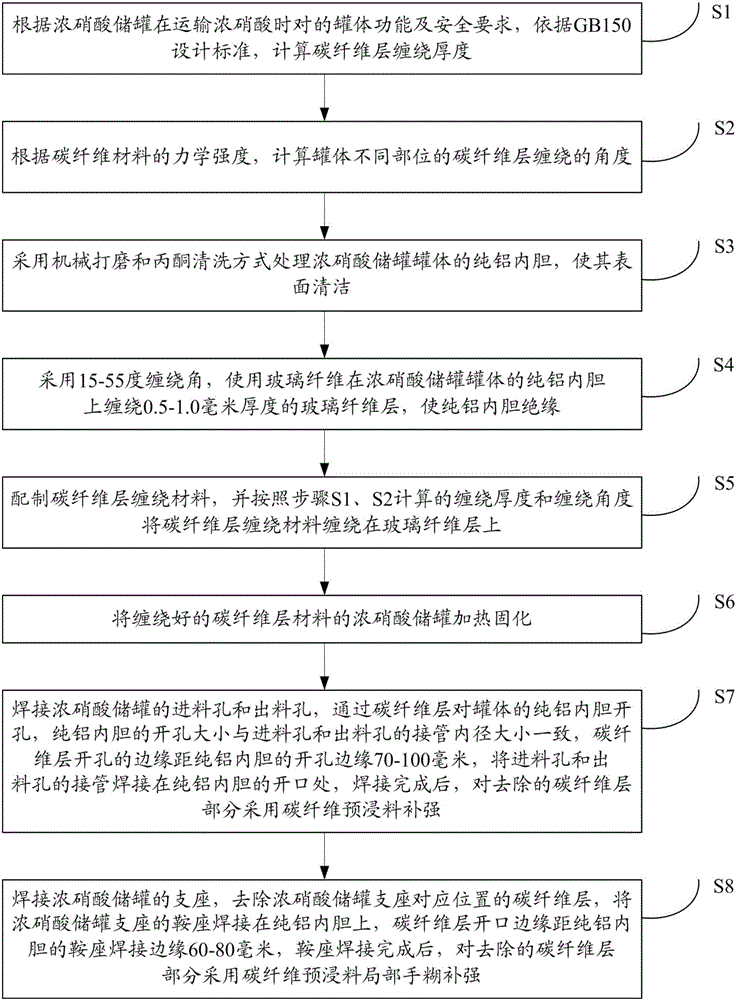

[0044] This embodiment discloses a method for preparing a concentrated nitric acid storage tank by winding carbon fibers, including the following steps:

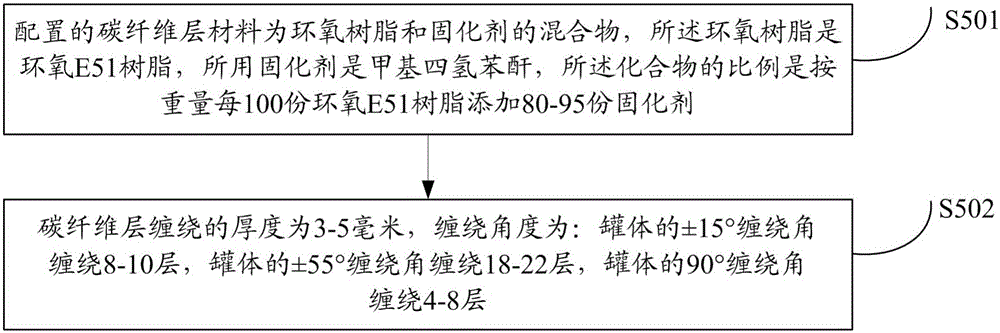

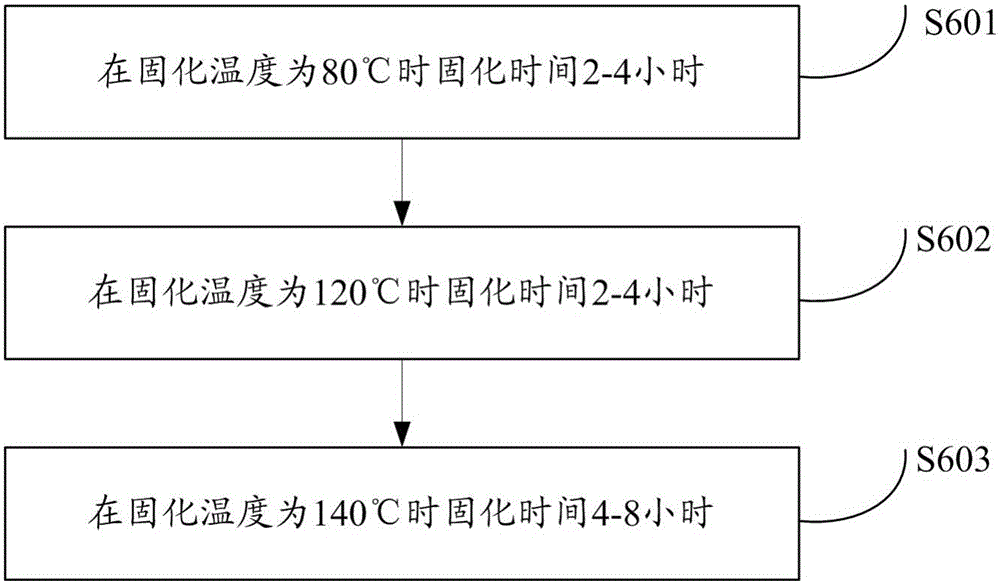

[0045] (1) According to the performance and safety requirements of the concentrated nitric acid storage tank, and according to the GB150 design standard, calculate the carbon fiber layer winding thickness. The carbon fiber layer winding thickness is 5 mm, and according to the mechanical strength of the carbon fiber material, calculate the carbon fiber layer winding at different parts of the tank The angle of winding is 15 degrees, 55 degrees, 90 degrees, and 8 layers of winding angles of 15 degrees, 20 layers of winding angles of 55 degrees, and 6 layers of winding angles of 90 degrees;

[0046] (2) Use mechanical grinding and acetone to clean the pure aluminum liner to make the surface clean;

[0047] (3) prepare the carbon fiber layer material for winding, the carbon fiber layer material is the mixture of epoxy resin and c...

Embodiment 2

[0054] This embodiment discloses a method for preparing a concentrated nitric acid storage tank by winding carbon fibers, including the following steps:

[0055] (1) According to the performance and safety requirements of the concentrated nitric acid storage tank, according to the GB150 design standard, calculate the winding thickness of the carbon fiber layer. The carbon fiber layer winding thickness is 4.5 mm. According to the mechanical strength of the carbon fiber material, calculate the carbon fiber layer winding at different parts of the tank The angle of winding is 15 degrees, 55 degrees, 90 degrees, and 9 layers of winding angles of 15 degrees, 18 layers of winding angles of 55 degrees, and 4 layers of winding angles of 90 degrees;

[0056] (2) Use mechanical grinding and acetone to clean the pure aluminum liner to make the surface clean;

[0057] (3) prepare the carbon fiber layer material for winding, the carbon fiber layer material is the mixture of epoxy resin and ...

Embodiment 3

[0064] This embodiment discloses a method for preparing a concentrated nitric acid storage tank by winding carbon fibers, including the following steps:

[0065] (1) According to the performance and safety requirements of the concentrated nitric acid storage tank, according to the GB150 design standard, calculate the winding thickness of the carbon fiber layer. The thickness of the carbon fiber layer is 5 mm. According to the mechanical strength of the carbon fiber material, calculate the carbon fiber layer winding at different parts of the tank The angle of winding is 15 degrees, 55 degrees, 90 degrees, and 10 layers of winding angles of 15 degrees, 20 layers of winding angles of 55 degrees, and 8 layers of winding angles of 90 degrees;

[0066] (2) Use mechanical grinding and acetone to clean the pure aluminum liner to make the surface clean;

[0067] (3) prepare the carbon fiber layer material for winding, the carbon fiber layer material is the mixture of epoxy resin and cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com