Method for producing diamond-like carbon film

A manufacturing method and technology of carbon film, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems affecting the smoothness and time-consuming of the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

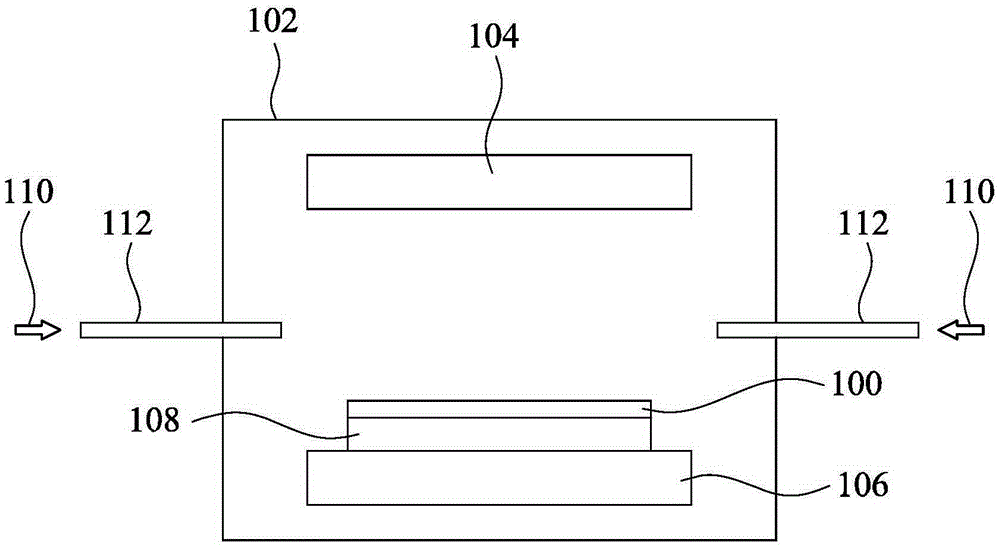

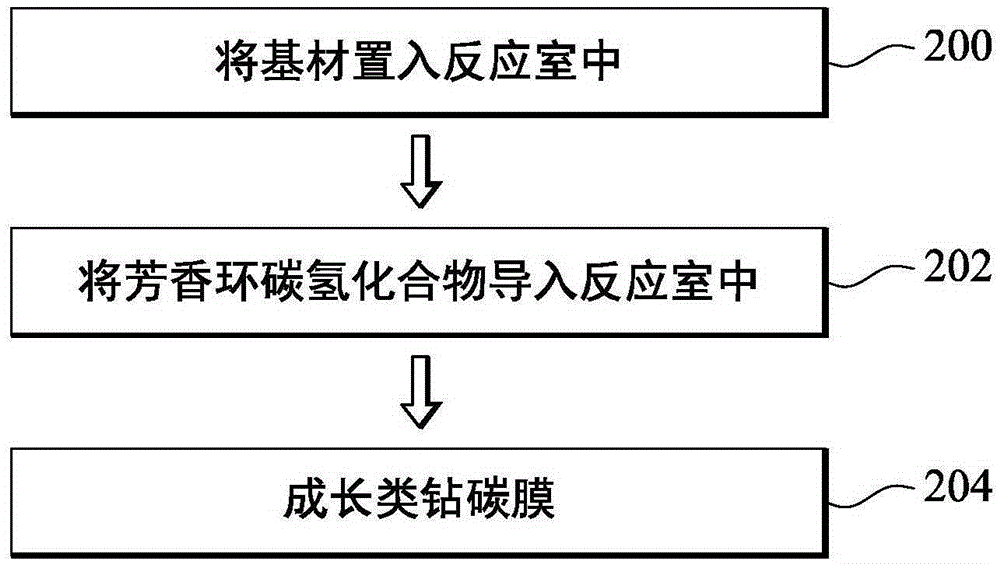

[0027] In view of the fact that the conventional diamond-like carbon film cannot grow at high temperature, and in a high-temperature application environment, it will deteriorate and cause a sharp drop in hardness, which severely limits the application of the diamond-like carbon film. Therefore, the present invention proposes a method for fabricating a diamond-like carbon film, which uses an aromatic ring hydrocarbon as a precursor for growing the diamond-like carbon film, and can grow the diamond-like carbon film at a high substrate temperature. Utilizing the high carbon-to-hydrogen ratio and benzene ring structure of aromatic ring hydrocarbons, it can still obtain less hydrogen and sp 3 structure (diamond structure) is rich and sp 2 High-hardness diamond-like carbon film with less structure (graphite structure). Moreover, since the hydrogen content in the diamond-like carbon film is small, the amount of hydrogen released by the diamond-like carbon film in a high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com