Sandwich panel with fire protection function and construction wall using the same

A technology of building walls and sandwich panels, applied in buildings, household walls, building components, etc., can solve the problems of re-occurrence of fire, easy to catch fire, and sandwich panels cannot fill water pipes, etc., to reduce fire losses and simplify building construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of a sandwich panel according to the present invention and a building wall using the same will be described in detail with reference to the accompanying drawings.

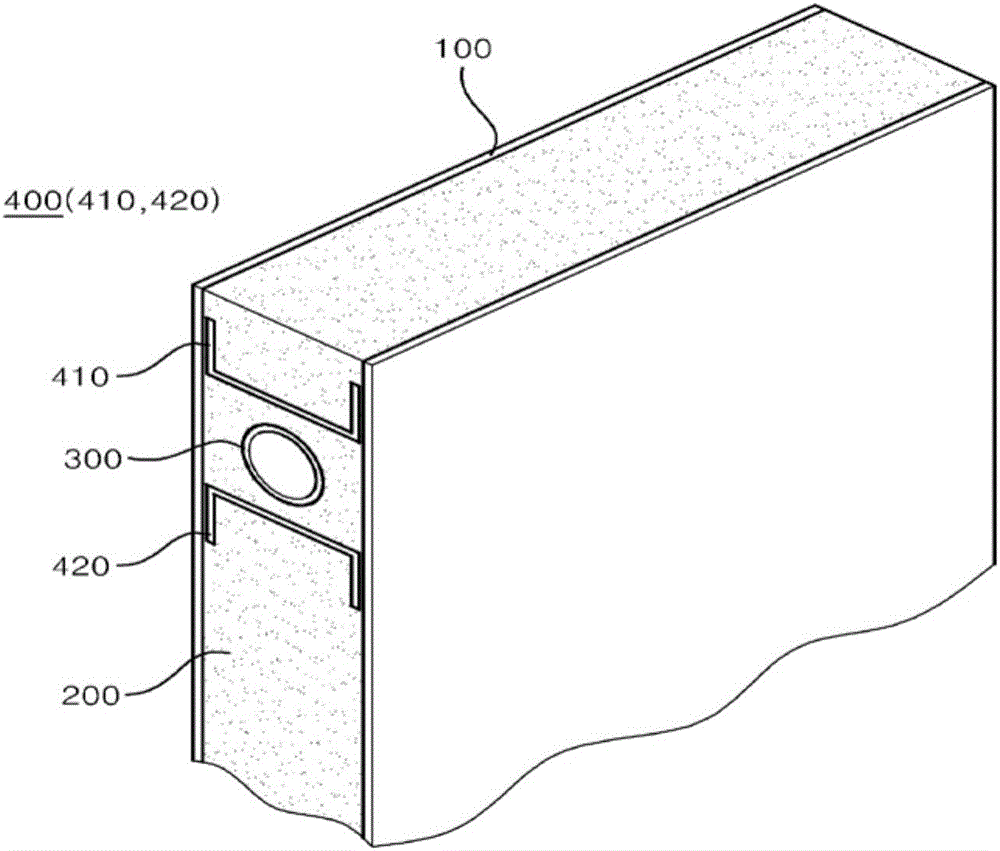

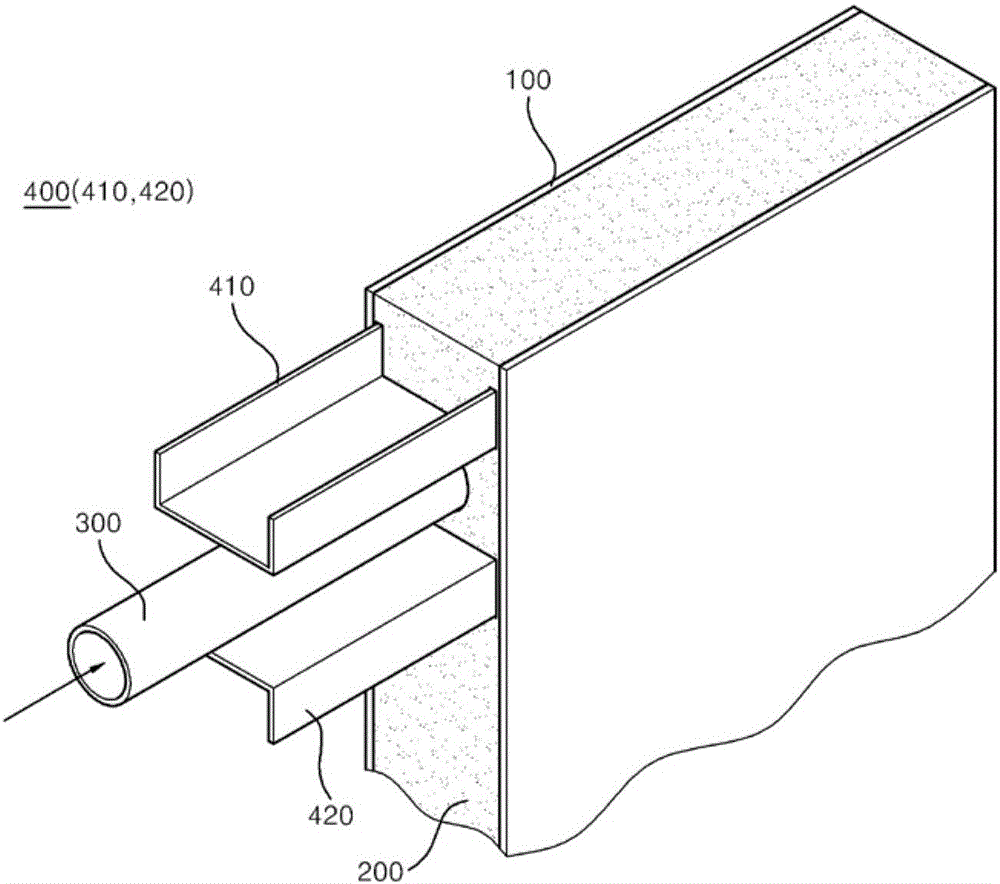

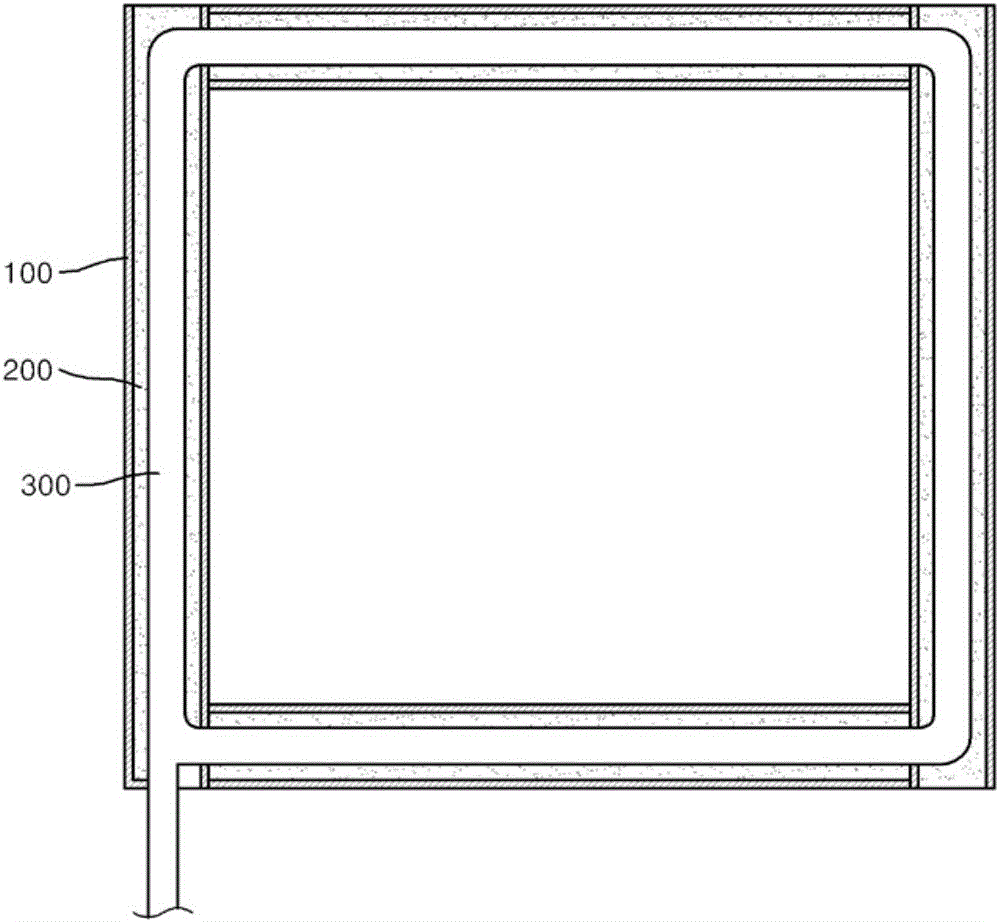

[0026] figure 1 is a perspective view of a sandwich panel according to the invention, figure 2 It is a perspective view of the sandwich panel from which the insulation board and water pipes are drawn, image 3 is a horizontal sectional view illustrating an installation configuration of a sandwich panel according to the present invention.

[0027] The sandwich panel according to the present invention is used as a building material for walls, wherein the heat insulating material 200 is filled between a pair of exterior panels 100 separated in parallel to each other, and the biggest feature of its structure is that when When a fire occurs and the heat insulating material 200 burns, the burning of the heat insulating material 200 can be extinguished by spraying water in the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com