Integrated stove

A technology for integrating stoves and stoves, applied in the field of integrated stoves, can solve problems such as unsatisfactory combustion efficiency and ineffective utilization of waste heat, and achieve the effects of being beneficial to combustion stability, good sealing and improving combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

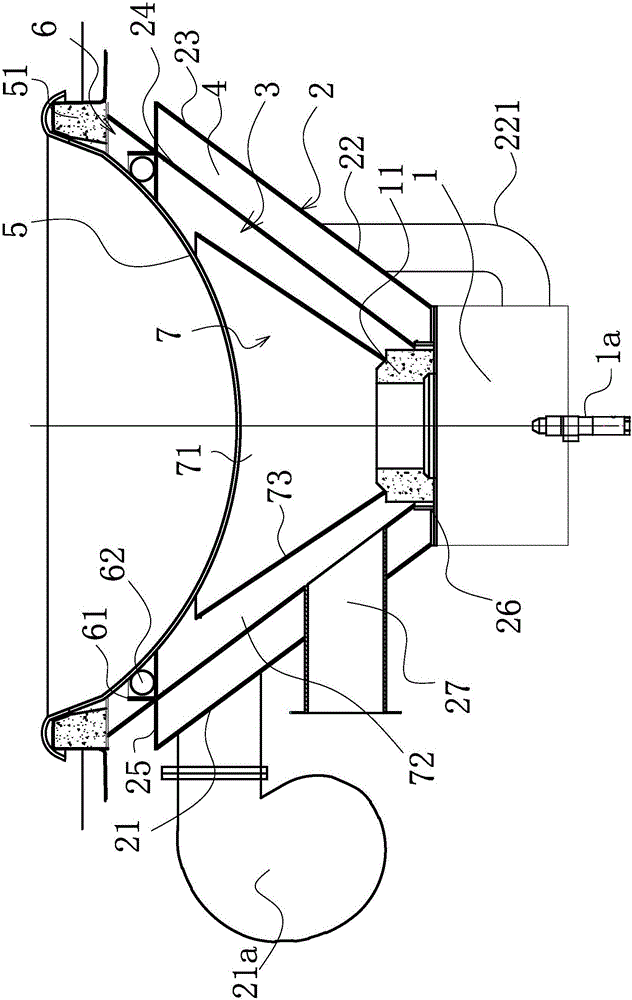

[0020] Such as figure 1 As shown, the integrated stove includes a combustion head 1. A stove head 11 is provided on the combustion head 1, a stove barrel 2 is provided on the periphery of the stove head 11, and the lower end of the stove barrel 2 is connected with the combustion head 1 so that the stove barrel 2 The inner side forms the stove 3 located above the combustion head 1. It is characterized in that the stove barrel 2 has an annular air interlayer 4 located between the inner and outer walls of the stove barrel 2, and when the integrated stove is in the working state, the air interlayer 4 The air in 4 can exchange heat with the hot air in the stove cavity 3. The stove cavity cylinder 2 is provided with a first passage 21 that penetrates the air interlayer 4 and allows external air to enter the air interlayer 4. The stove cylinder body 2 is also provided There is a second passage 22 that penetrates the air interlayer 4 and allows the air in the air interlayer 4 to enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com