Determination device and method for mine tailing filling grain class distribution rules

A technology of distribution rules and measuring devices, which is applied in the direction of measuring devices, particle size analysis, particle and settlement analysis, etc., can solve problems affecting filling operations, time-consuming, labor-intensive, impact, etc., to simplify the measuring device and operation method, and scientific and effective measuring results , Simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

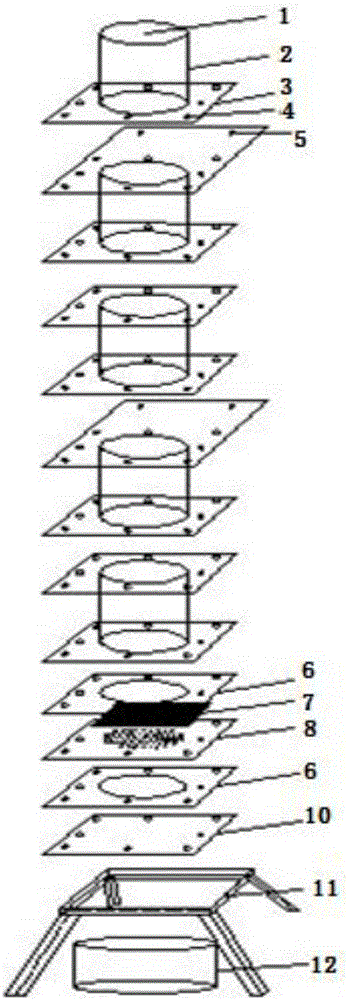

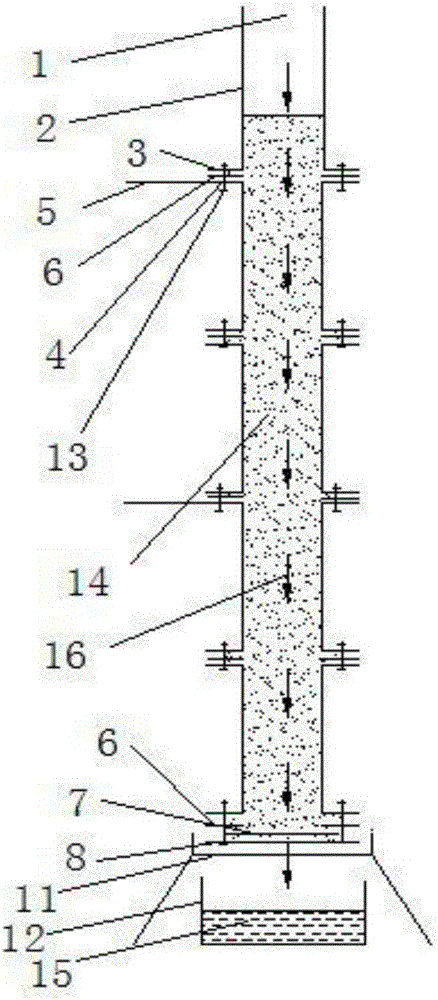

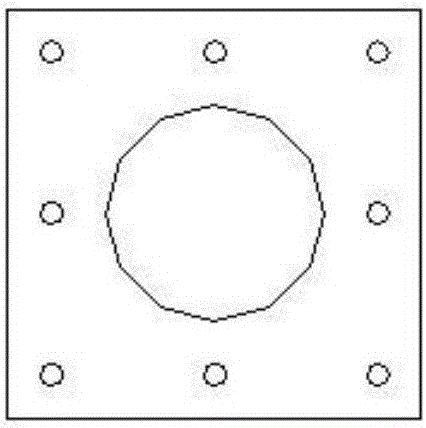

[0031] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

[0032] Such as figure 1 , figure 2 As shown, a device for measuring particle size distribution of mine tailings filling includes a bracket 11 , an infiltration device and a container 12 , the infiltration device is placed on the frame 11 , and the container 12 is placed in the space at the bottom of the frame 11 . The permeation device includes a plurality of organic glass tubes 2, flange connection plate 3, rubber leather pad 6, permeation filter cloth 7, permeation baffle 8, and closed baffle 10; the ends of each organic glass tube 2 are respectively bonded and fixed with flanges Connecting plate 3, each plexiglass tube 2 is sealed and fixedly connected in the vertical direction sequentially through the flange connecting plate 3 bonded at its end, and enough plexiglass tubes 2 are connected to form a cavity 1 for accommodating the tailing mortar body 14 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com