Fluid separation systems and methods

A fluid separation and fluid technology, applied in the field of fluid separation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

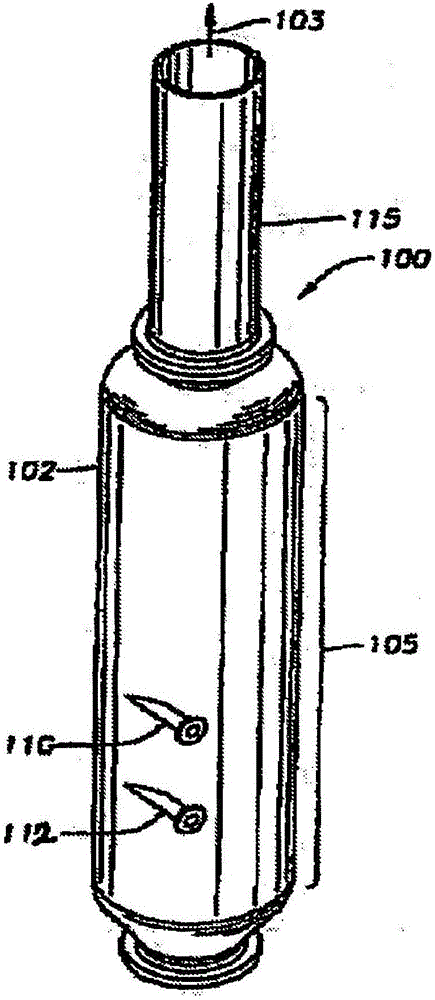

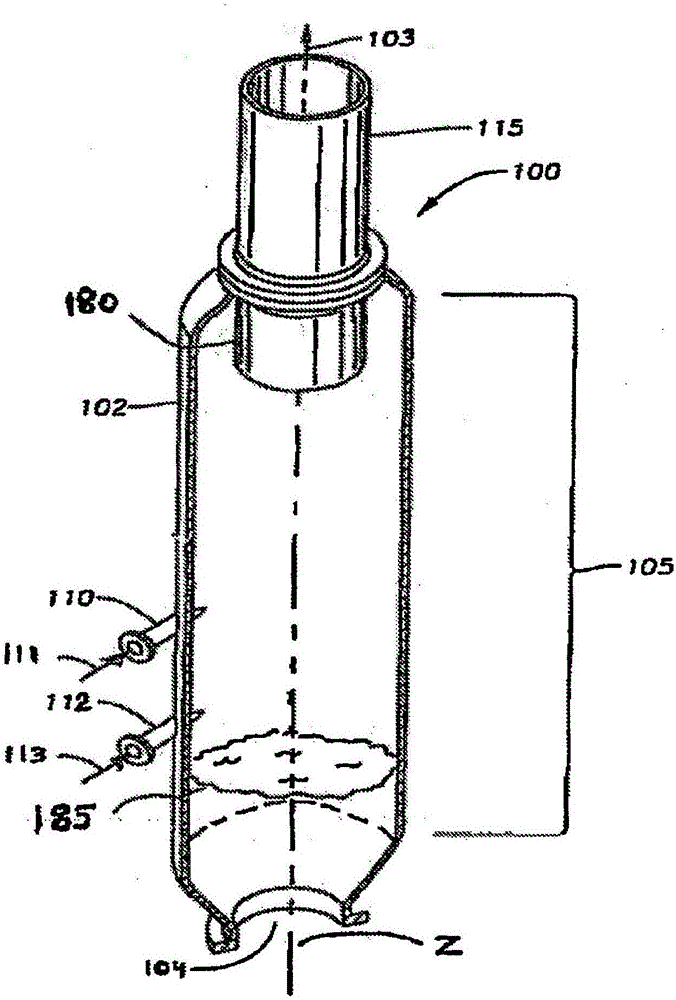

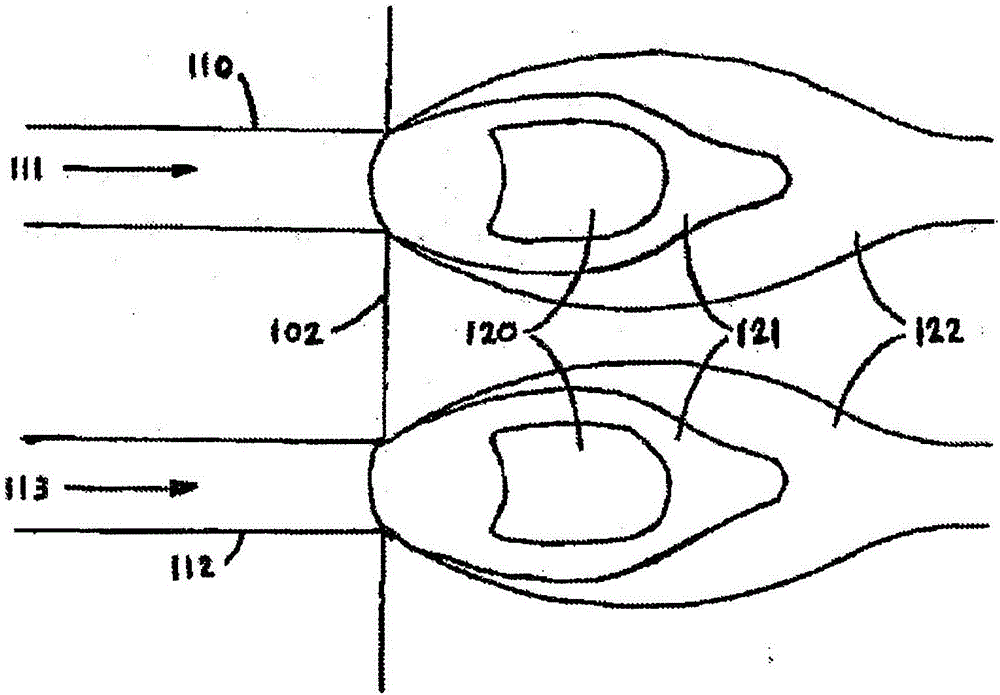

[0059] A Computational Fluid Dynamics ("CFD") model was developed to simulate the Example separation system in reactor shutdown conditions. The modeled system is 12.08m 3 , which includes a cylindrical vessel with an inner diameter of 2040mm and a vertical fluid outlet with a diameter of 895.25mm. The separation system includes two fluid inlets defined in the inner cylindrical surface of the vessel, one fluid inlet positioned directly above the other, configured to direct fluid flow in a counterclockwise direction tangential to the inner surface. The liquid level in the vessel was 200mm below the lower fluid inlet.

[0060] The model is that the model is based on certain initial boundary conditions of both the input and the output of the separation system. For fluid inlets, use a theoretical inlet tank to model the initial conditions for the shape of a rectangular cuboid. The upstream face of the inlet tank is set as the inlet face, from which the initial boundary condition...

Embodiment 2

[0067] Example 2 had the same conditions as Example 1, with a few exceptions: The fluid inlets were positioned 180 degrees from each other about the central vertical axis of the vessel. The lower fluid inlet is set to deliver 360kg / s while the upper fluid inlet is set to deliver 520kg / s. The fluid outlet diameter increased to approximately 1016mm. Under these conditions, a generally subsonic circulation develops within the vessel, at the outlet of the fluid is a steady state flow and an expanding jet. The separation system is subjected to localized wall pressures of the order of 4 bar at the fluid outlet, 22 bar on the inner surface of the vessel, and up to 40 bar near the fluid inlet.

Embodiment 3

[0068] Embodiment 3 (comparison)

[0069] Example 3 had the same conditions as Example 2, except that the fluid inlets were at the same vertical level. Under these conditions, a general ultrasonic circulation develops within the vessel, with an unsteady flow through the fluid outlet. The separation system is subjected to localized wall pressures of the order of 5 bar at the fluid outlet, 37 bar on the inner surface of the vessel, and up to 50 bar near the fluid inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com