A device and a method used for separating light thin film from plants through breaking

A crushing device and plant technology, applied in grain processing, collectors, agricultural machinery and tools, etc., can solve problems such as crop damage, improper methods, and reduced water penetration, achieving labor-saving and high-efficiency crushing, low production costs, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

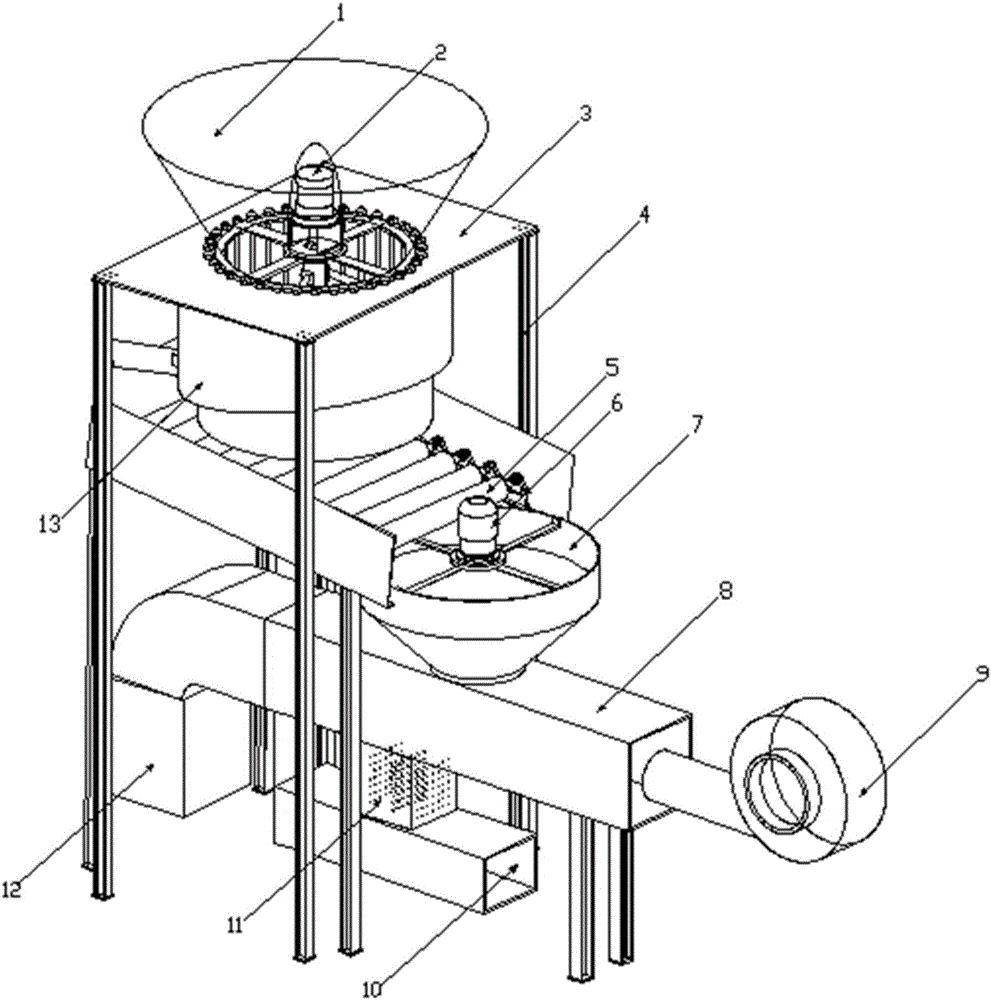

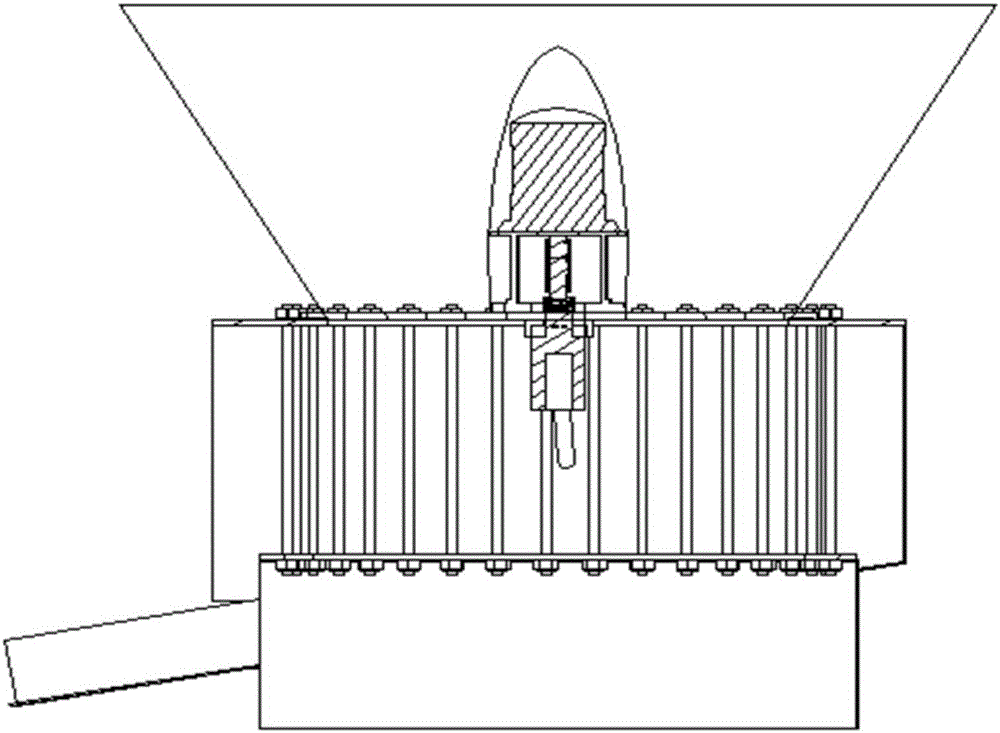

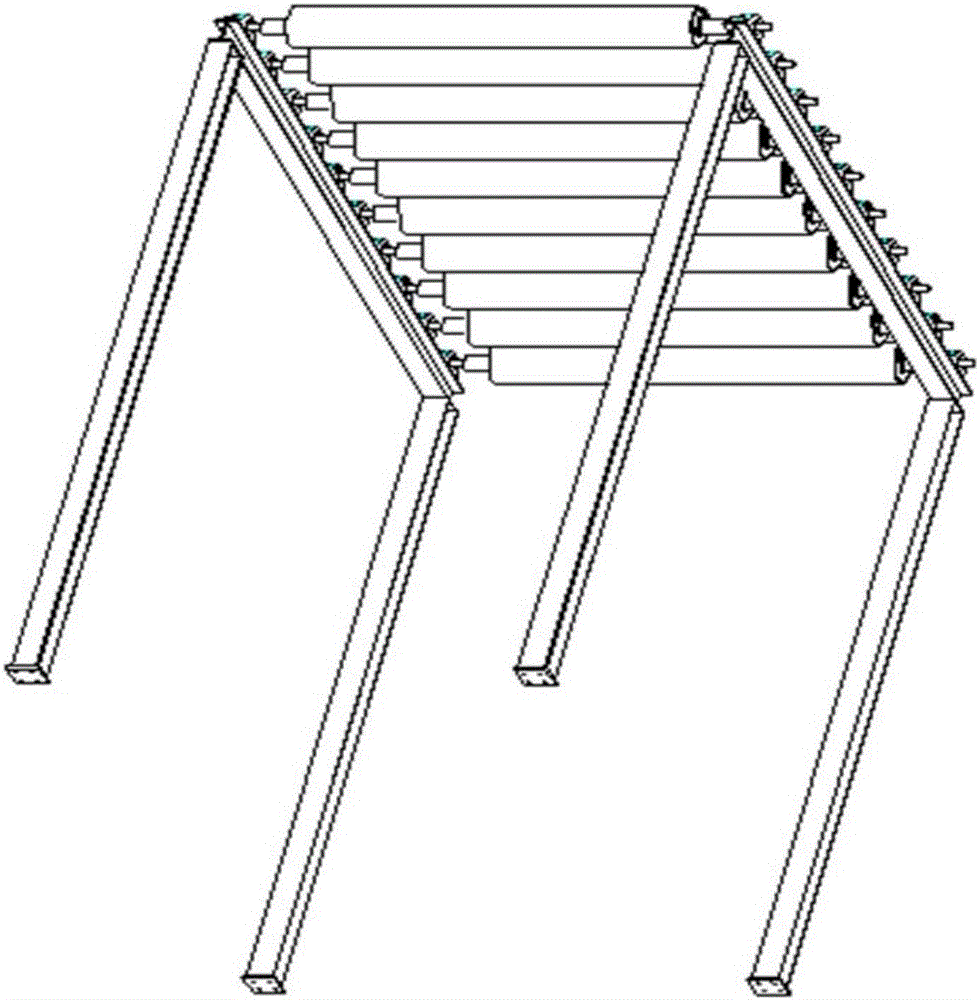

[0027] see figure 1 The plant separation light film crushing device of the present invention includes a centrifugal separation mechanism, a roller conveying mechanism, a crushing and winnowing mechanism and an electrostatic adsorption mechanism arranged sequentially from top to bottom; the centrifugal separation mechanism includes an inverted funnel-shaped feed port 1 and a The centrifugal separation drum 13 connected to the feeding port 1, the center of the bottom of the feeding port 1 is installed with a rotary grab for throwing off soil particles through the centrifugal motor 2; the bottom surface of the centrifugal separating drum 13 has a discharge port, and the roller conveying mechanism includes a The roller conveyor 5 directly below the centrifugal separation cylinder 13; the crushing and winnowing mechanism includes a crushing cylinder 7 arranged bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com