Multi-point sampling and measurement system for exhaust smoke from inlet and outlet of denitration CEMS of thermal power plant

A technology for thermal power plants and measurement systems, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve problems such as blockage of sampling pipes, influence of downstream equipment, and unfavorable safe operation of units, so as to reduce the probability of blockage and the measurement value. Accurate and stable, the effect of reducing the probability of ammonia overspray and underspray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific embodiments and drawings, but it is not intended to limit the present invention.

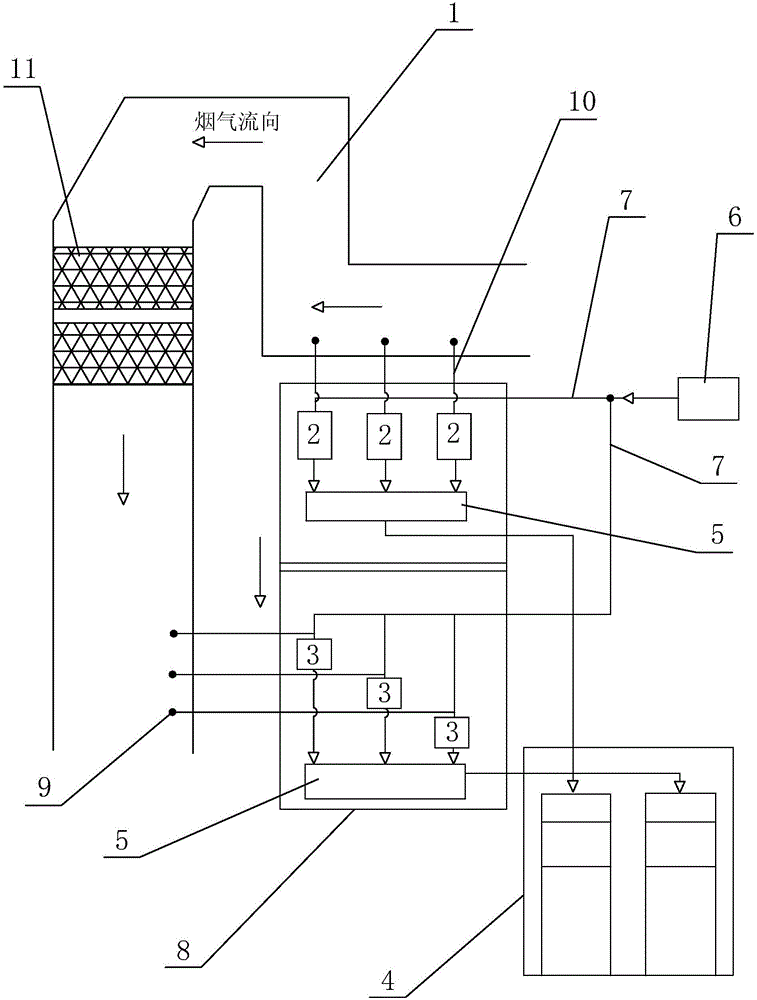

[0019] Such as figure 1 As shown, the flue gas multi-point sampling measurement system at the entrance and exit of the denitrification CEMS in a thermal power plant includes a backflushing device 6 and two flue gas analyzers 4, and the flue gas analyzers 4 are respectively an inlet flue gas analyzer and an outlet flue gas analyzer. The instrument also includes a first gas collection box 5 and more than two inlet sampling devices 2. The detection probe 9 of each inlet sampling device 2 stretches into the sampling port on the flue 1 inlet and the output end of each detection probe 9 is connected with a sampling pipe 10, and the sampling pipe 10 is connected with the gas collection box 5 after the inlet sampling device 2 The inlet is connected, and the outlet of the gas collection box 5 is connected to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com