Welding car for contact warning

A technology for welding trolleys and frames, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slipping, accidental loss, and interference of welding trolley running speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

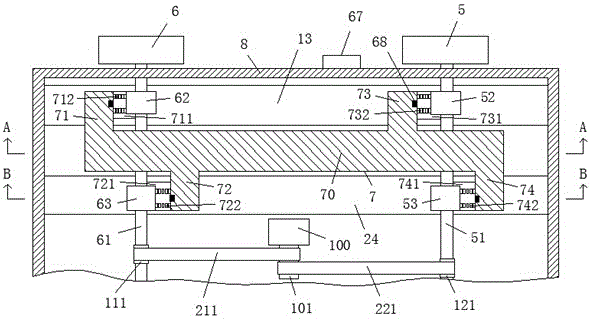

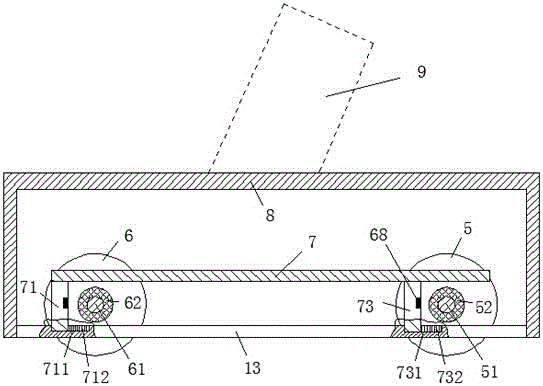

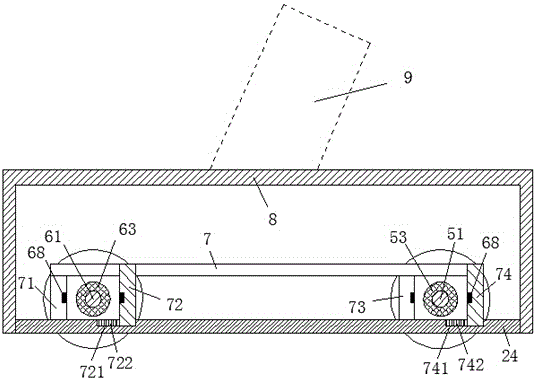

[0010] Refer below Figure 1-3 Instead, examples of the present invention will be described.

[0011] The contact alarm welding trolley according to the embodiment includes a frame body 8 for carrying a welding torch 9, a front wheel shaft 61 fixedly mounted with the front wheel 6 and rotatably connected with the frame body 8, and a rear wheel 5 fixedly mounted thereon and The rear wheel shaft 51 rotatably connected with the frame body 8, the front wheel shaft 61 is separately installed with the first one-way bearing 62 of the front shaft and the second one-way bearing of the front shaft in the opposite direction of rotation in the axial direction. Bearing 63, described rear axle 51 is separately installed with the first one-way bearing 52 of rear axle and the second one-way bearing 53 of rear axle that can rotate direction opposite in the axial direction, described front axle 61 is also provided with Front driving wheel 111, described front driving wheel 111 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com