Patents

Literature

42results about How to "Does not affect power control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding device

InactiveCN105880893AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

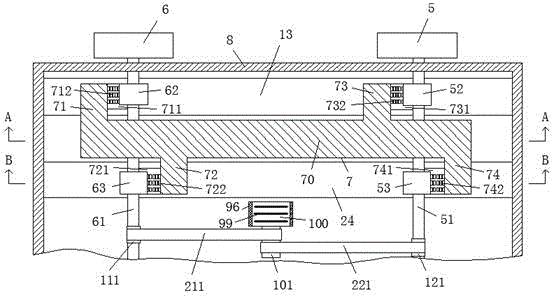

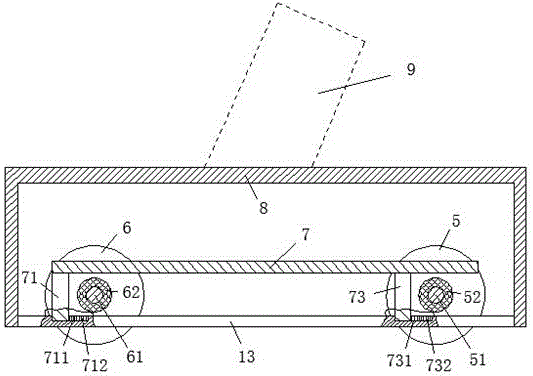

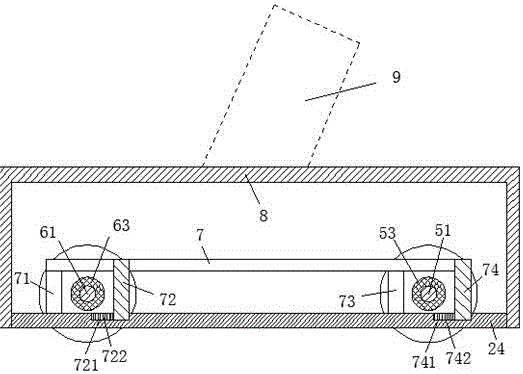

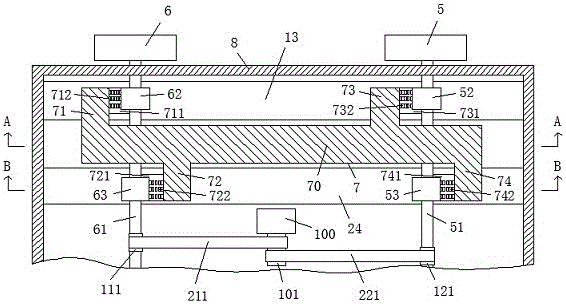

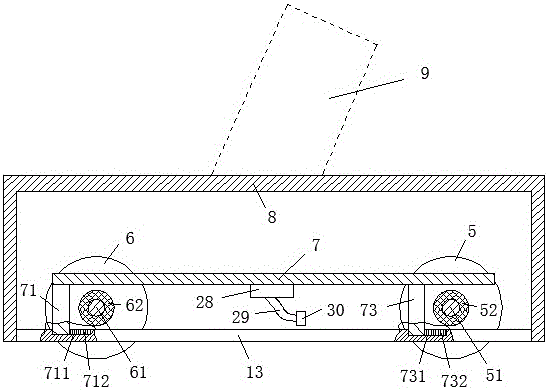

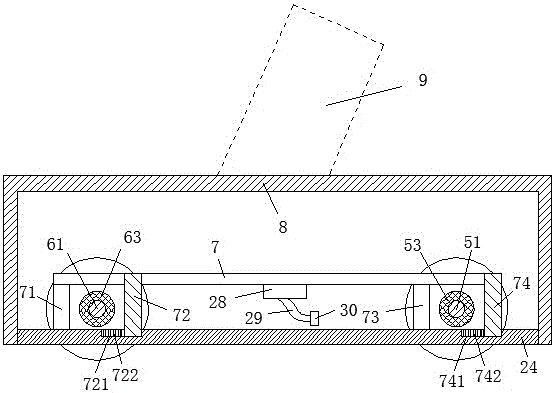

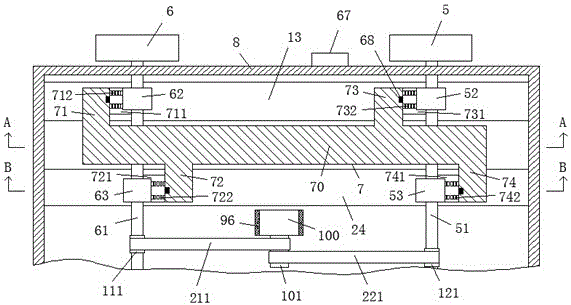

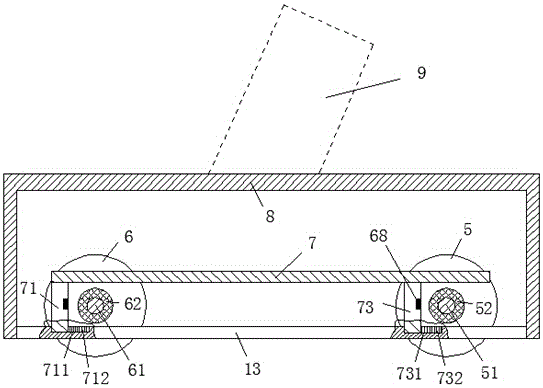

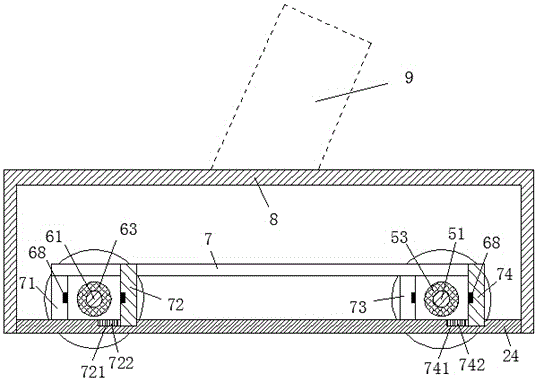

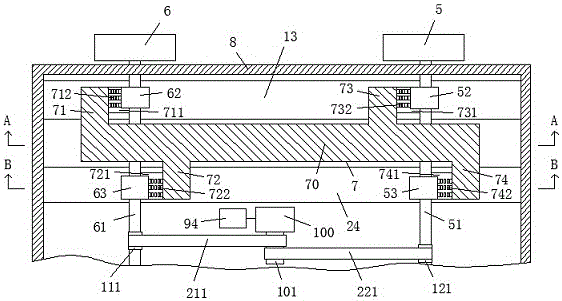

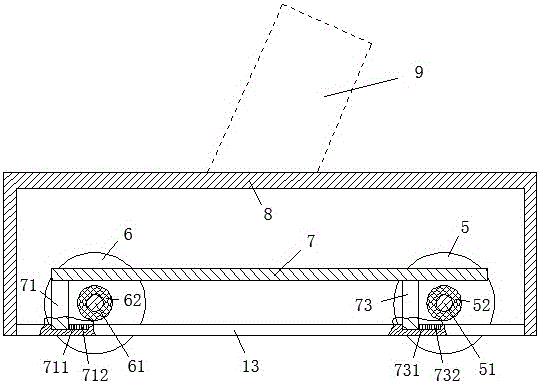

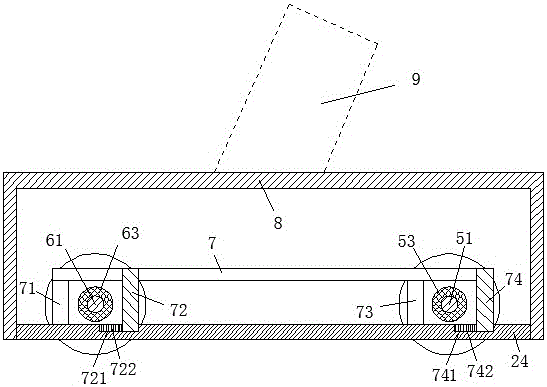

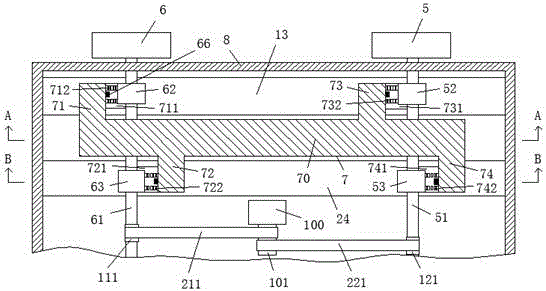

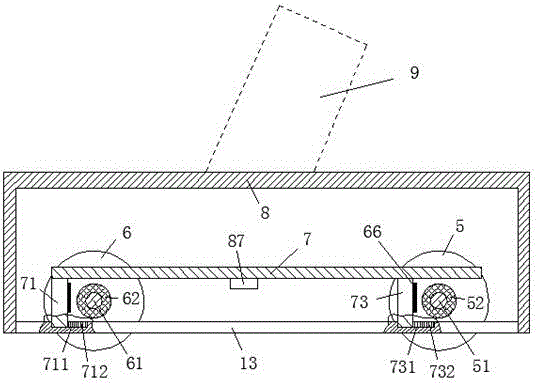

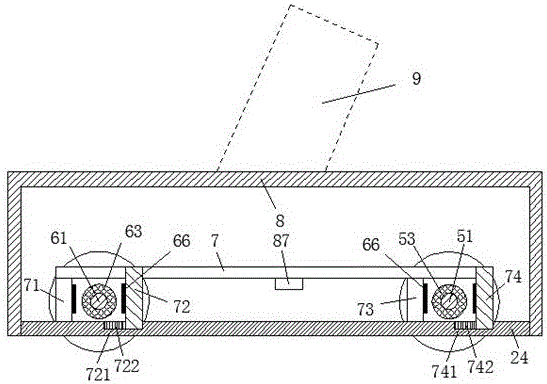

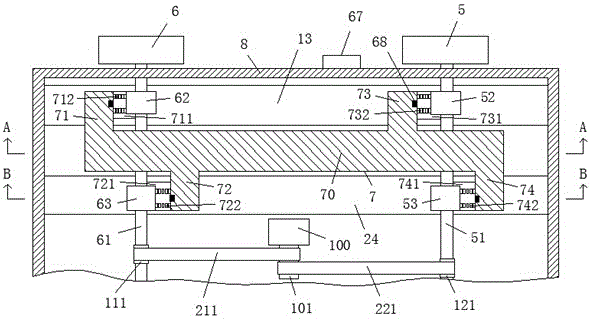

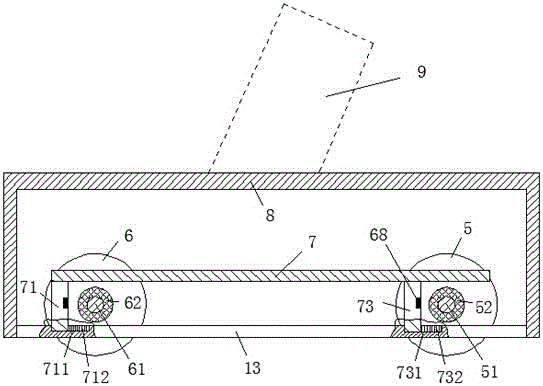

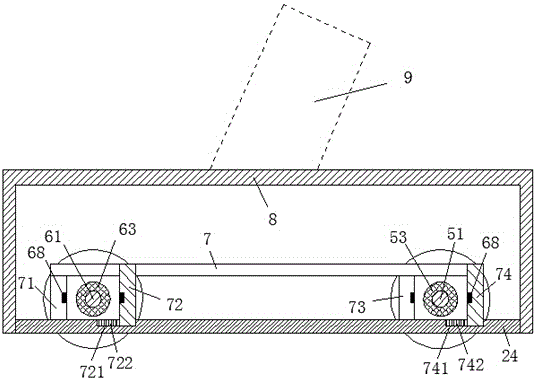

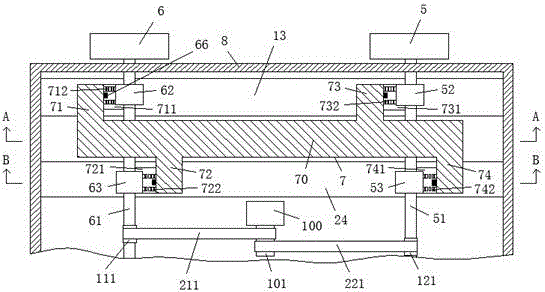

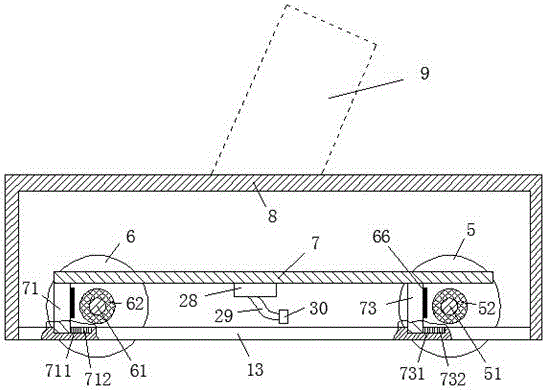

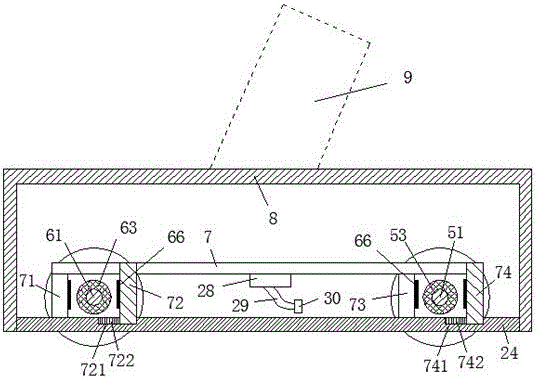

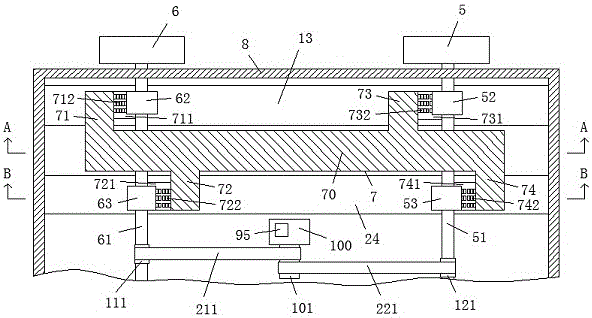

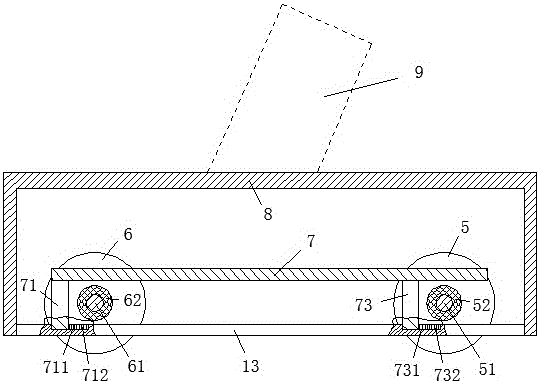

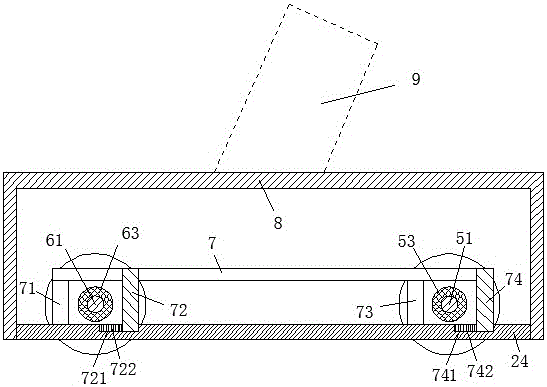

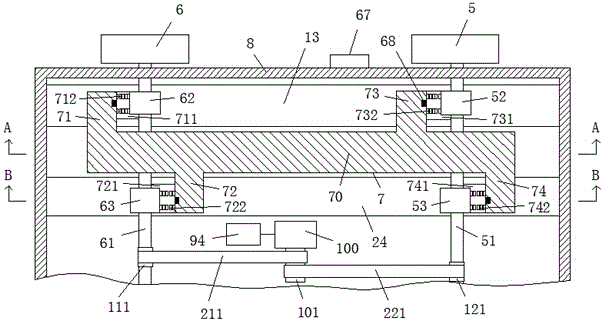

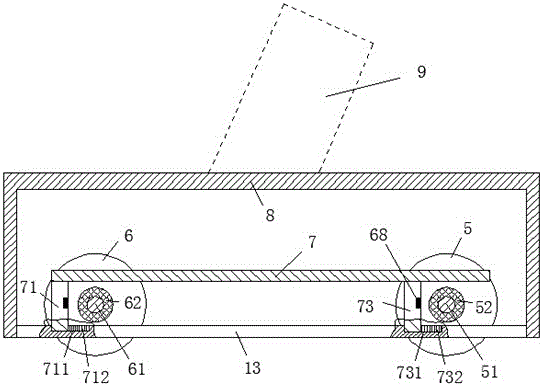

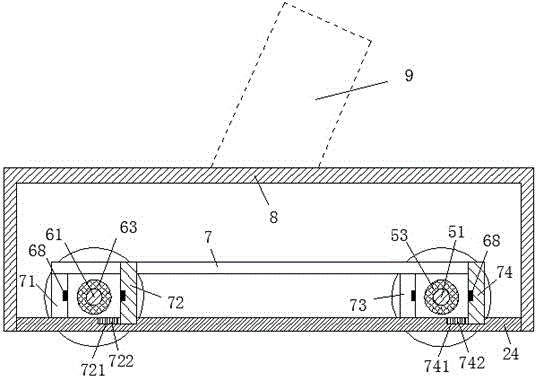

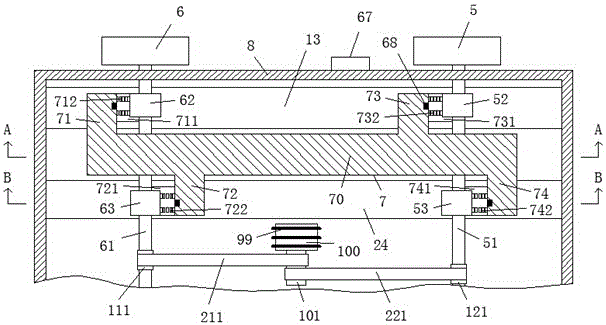

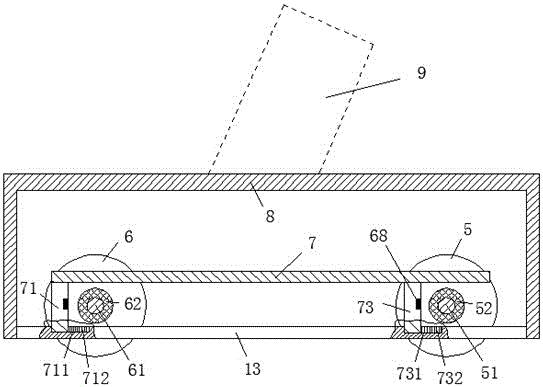

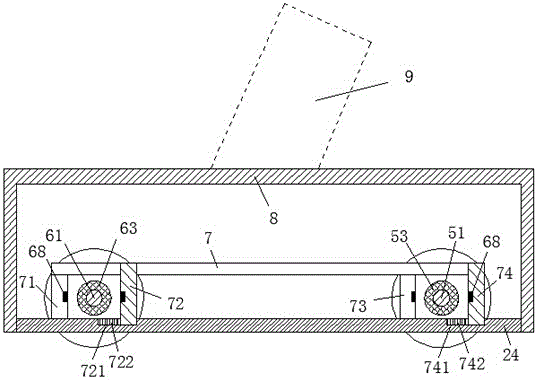

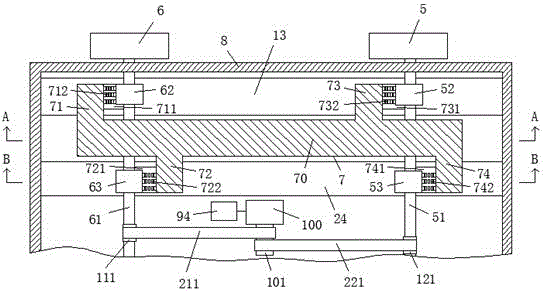

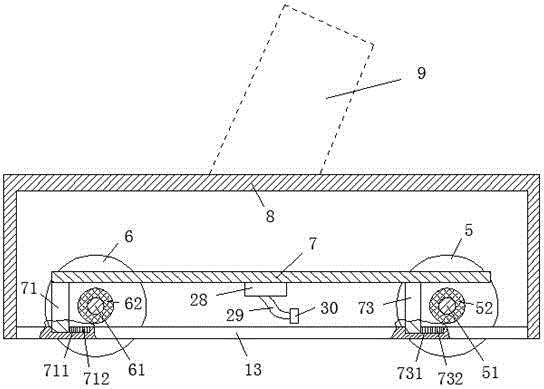

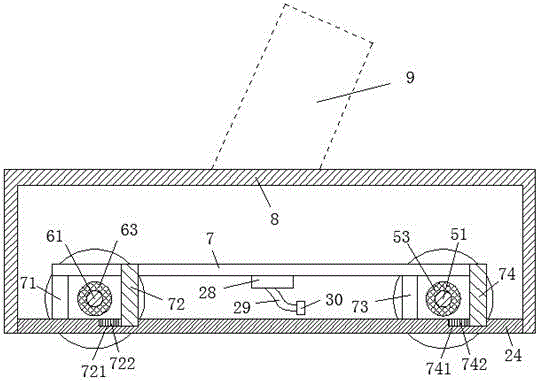

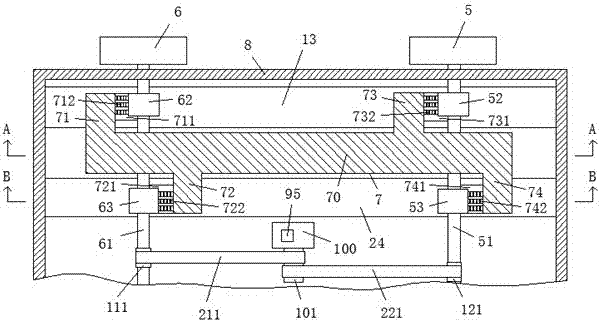

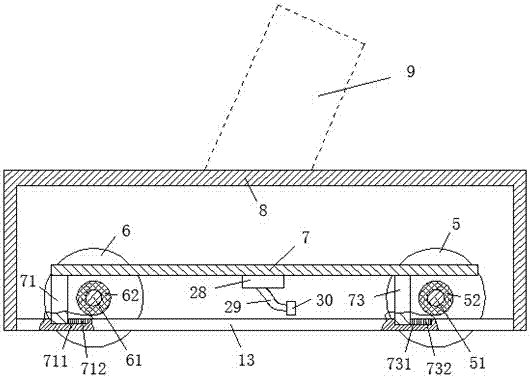

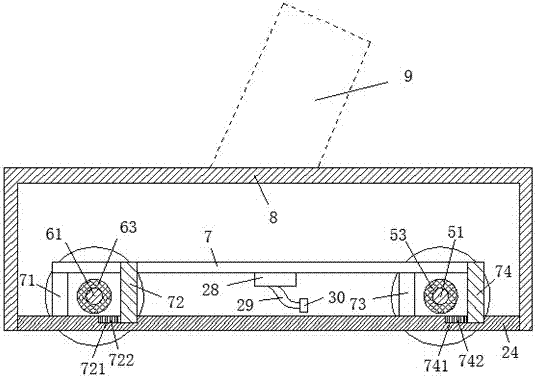

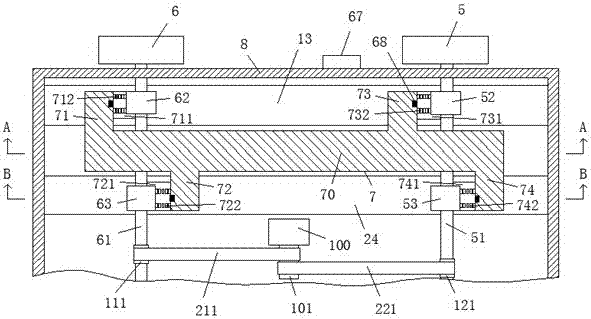

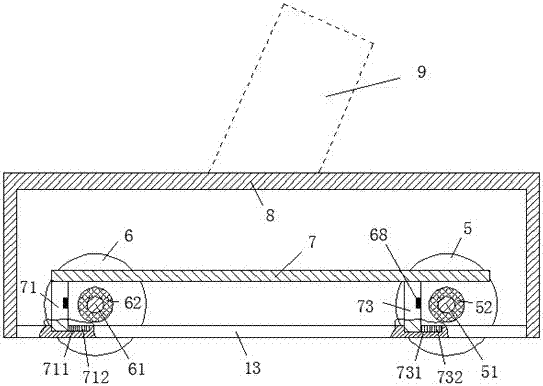

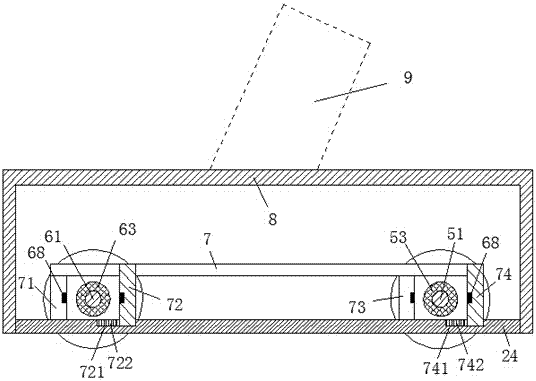

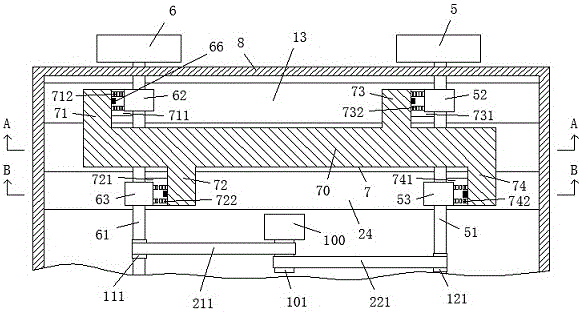

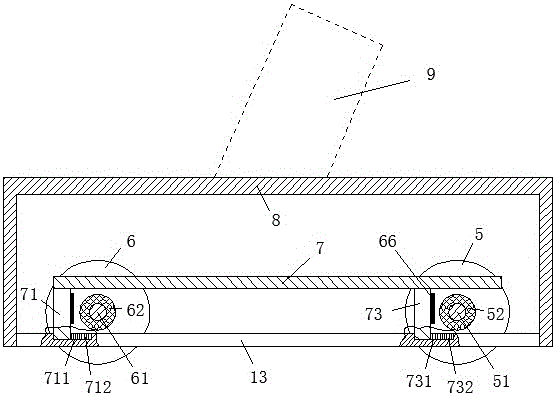

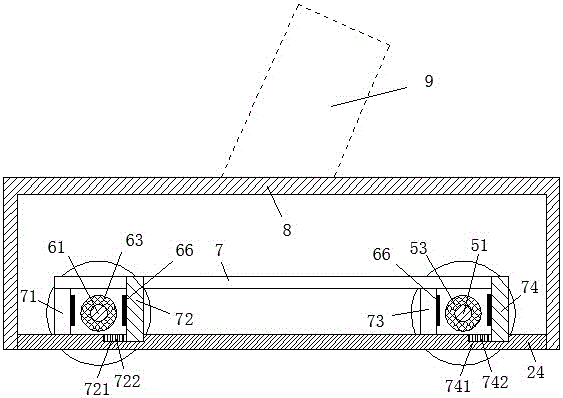

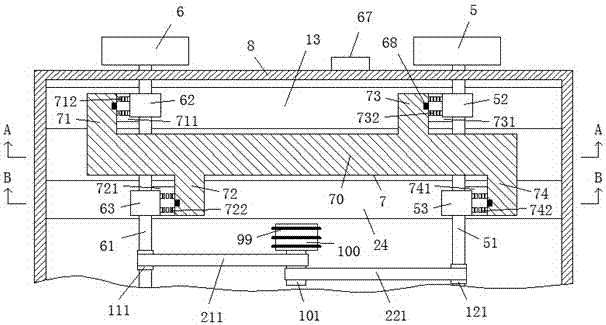

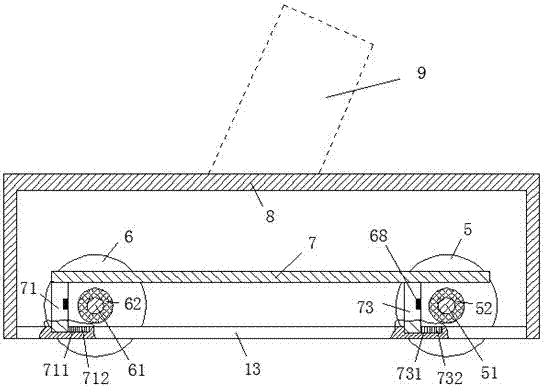

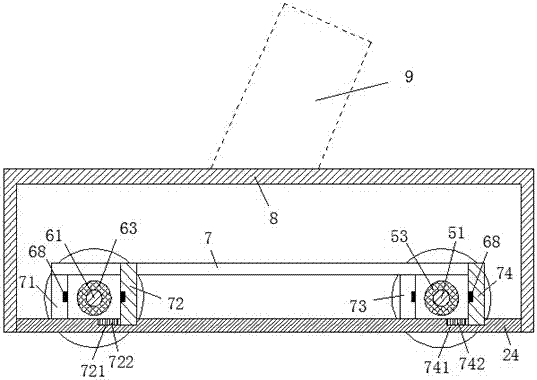

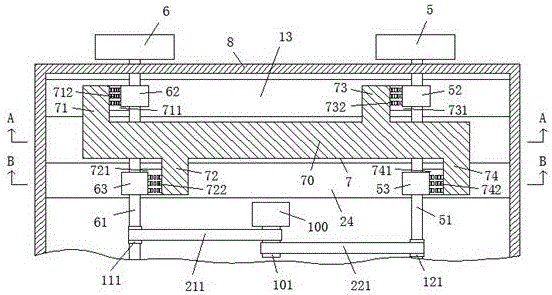

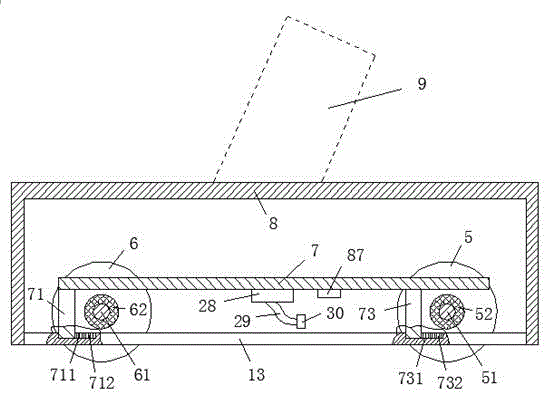

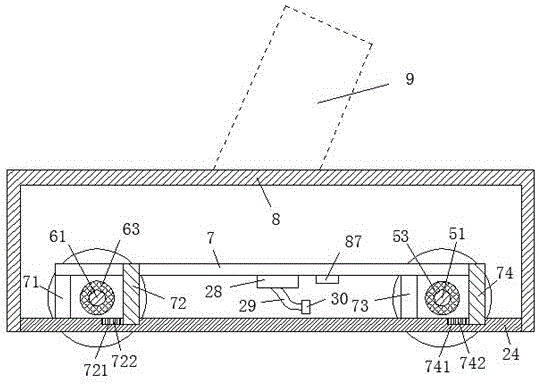

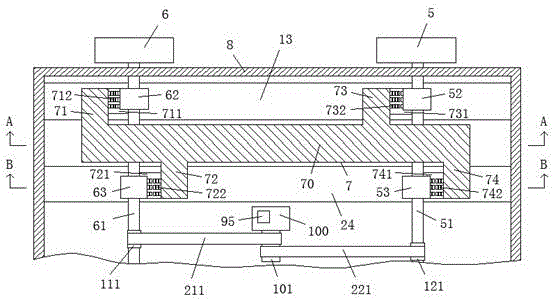

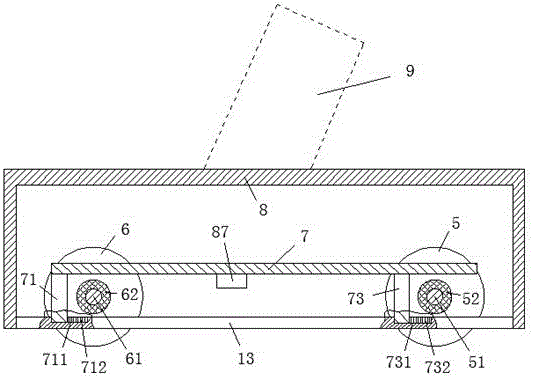

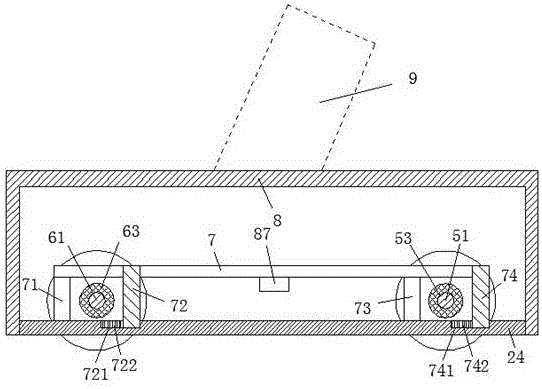

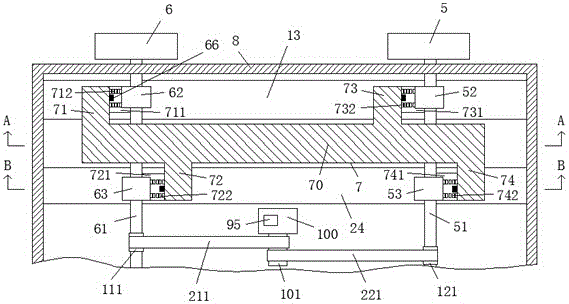

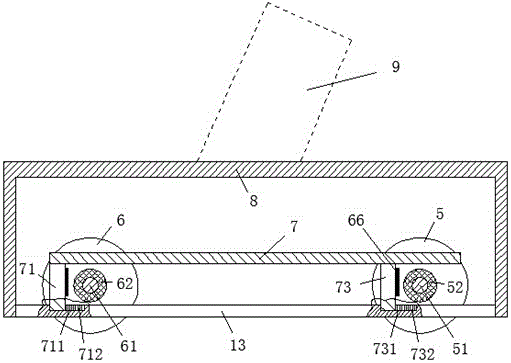

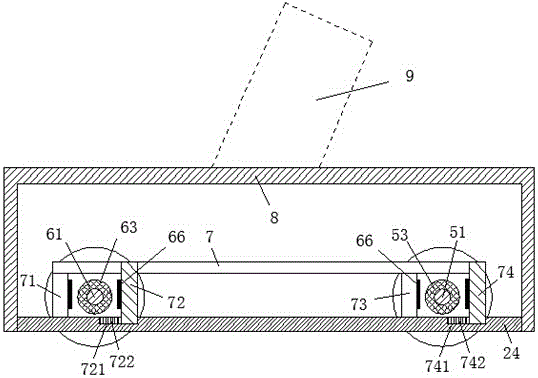

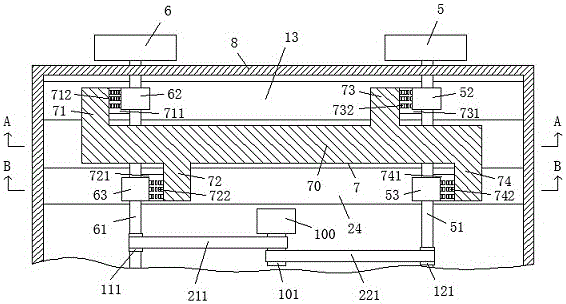

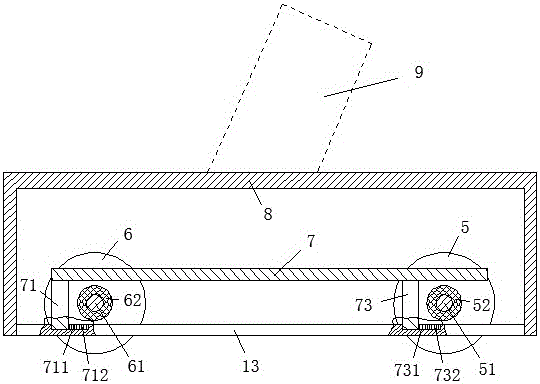

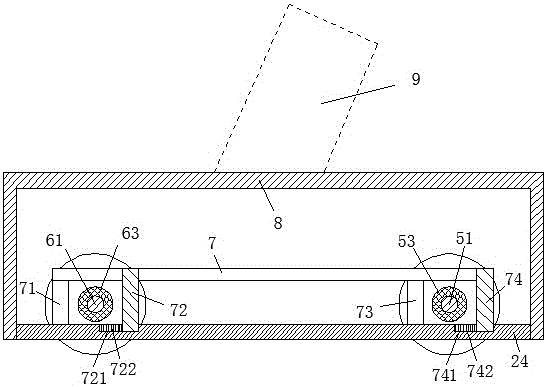

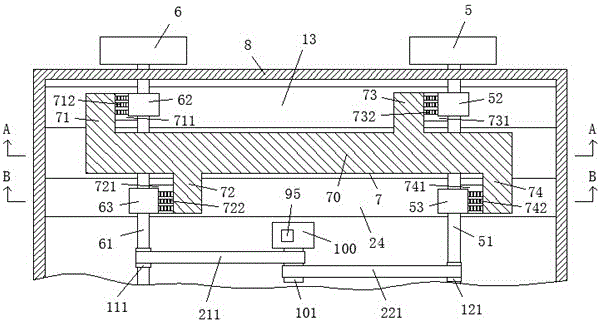

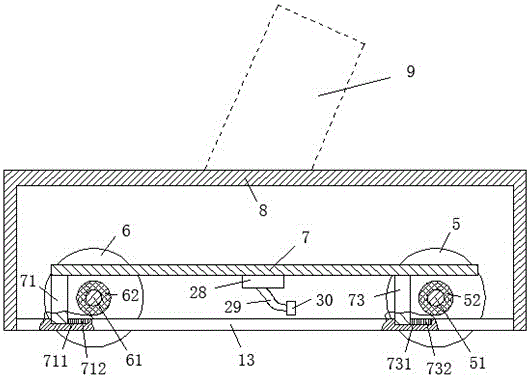

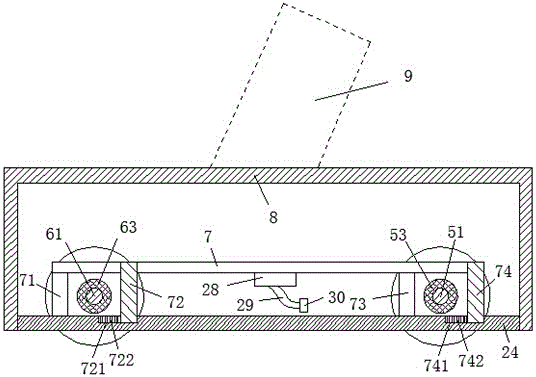

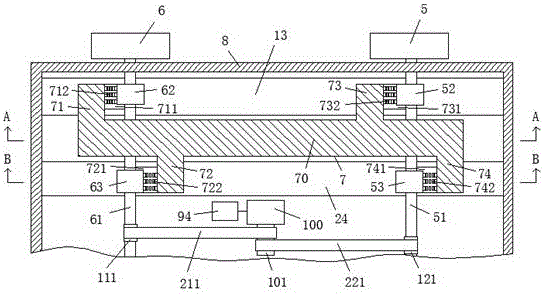

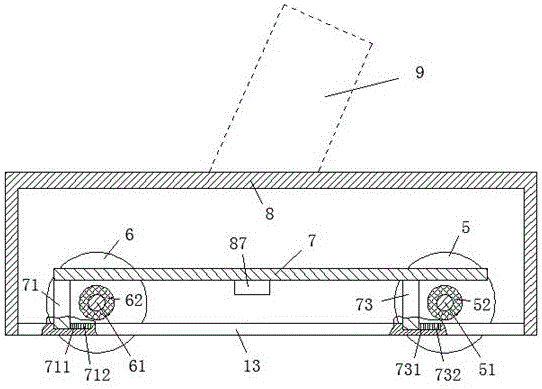

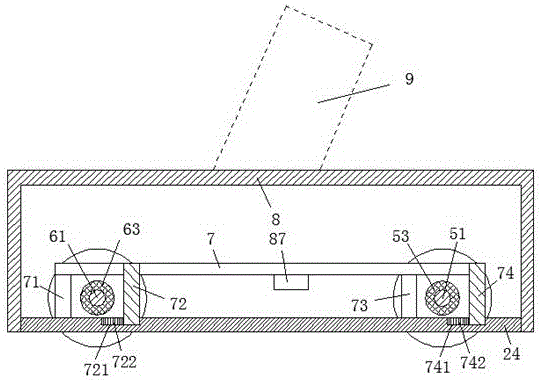

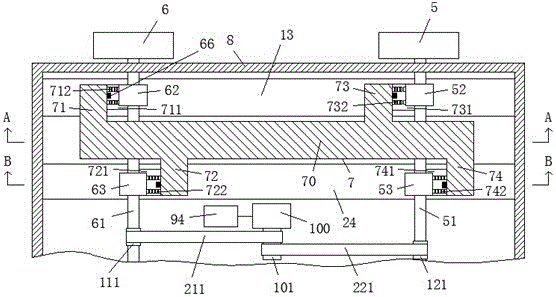

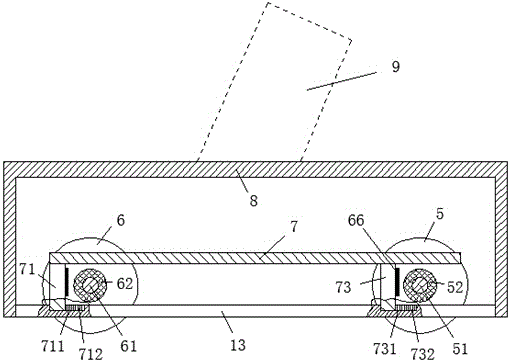

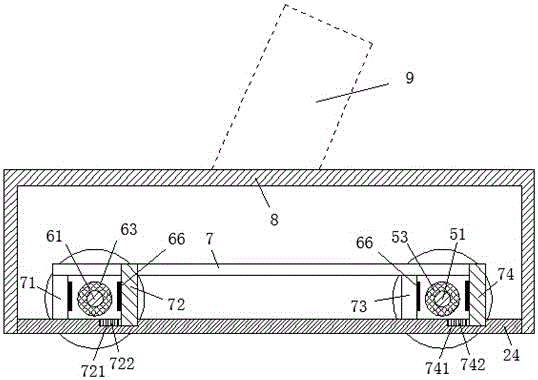

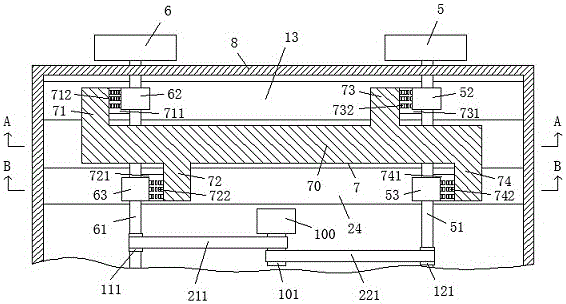

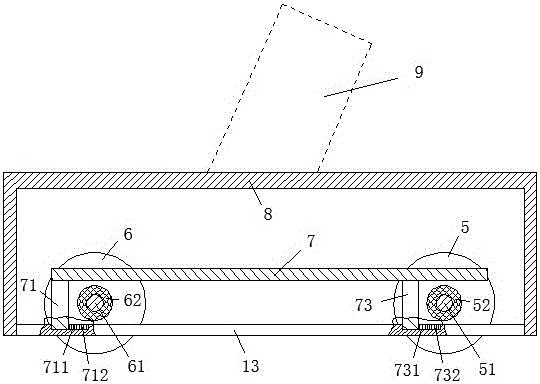

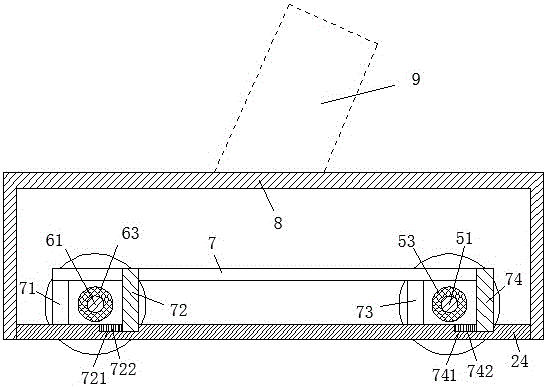

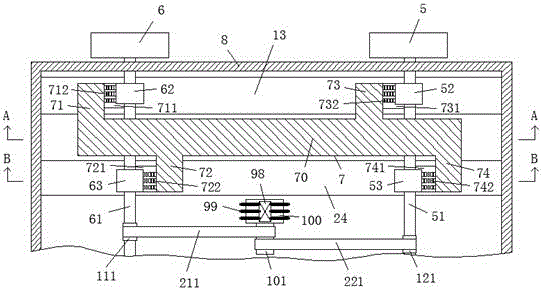

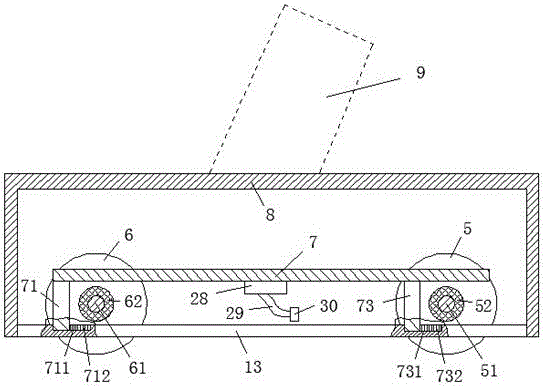

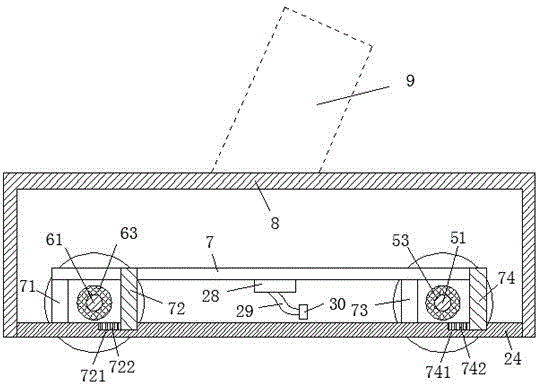

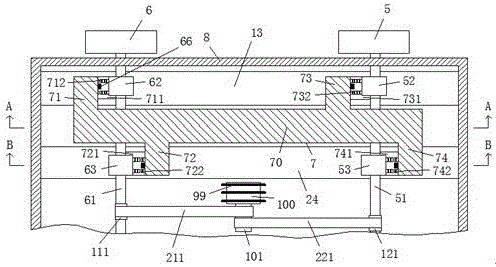

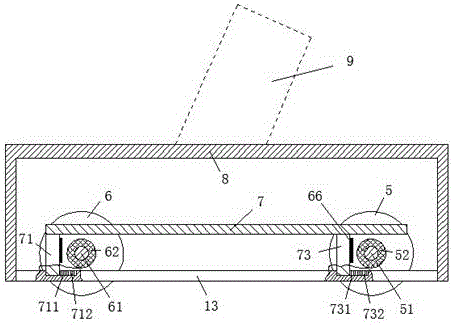

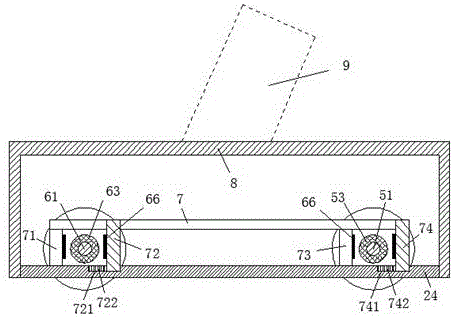

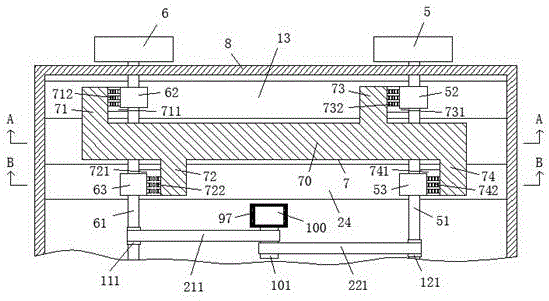

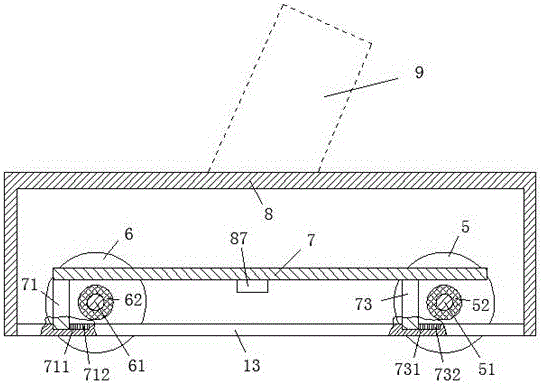

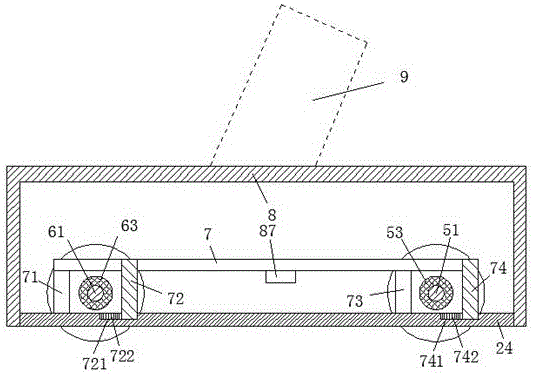

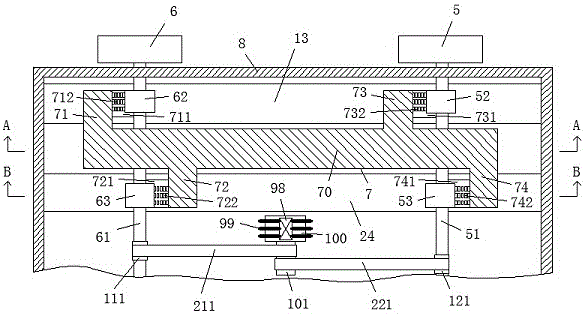

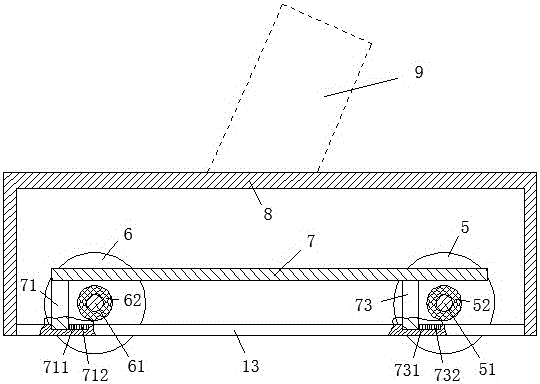

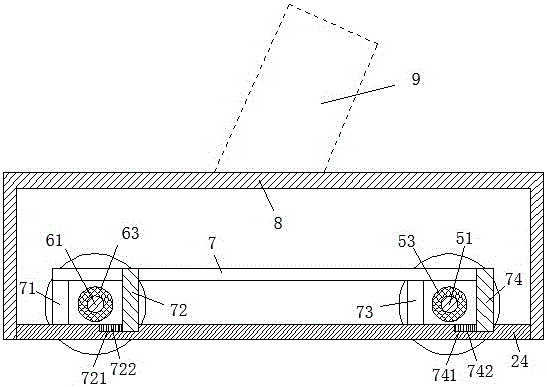

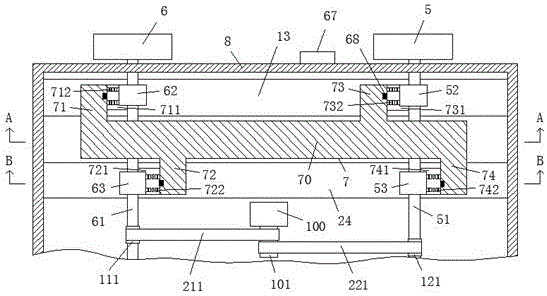

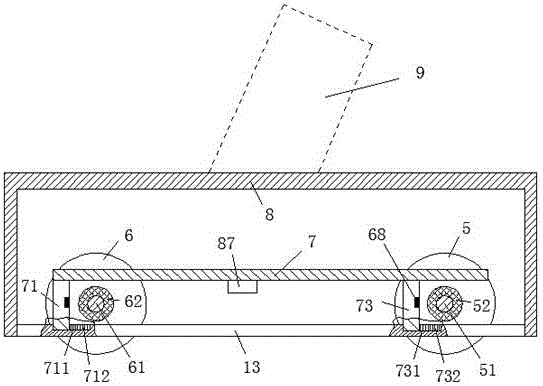

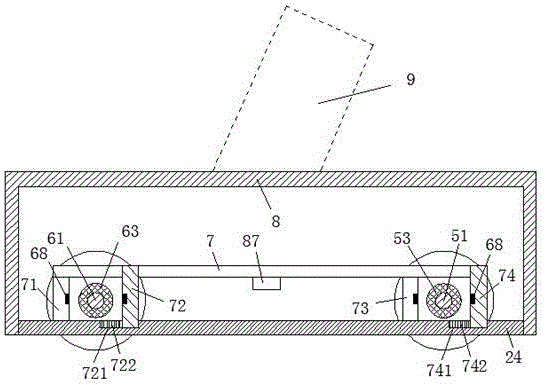

A welding device, comprising a frame body (8) for carrying a welding torch (9), a front wheel shaft (61) fixedly mounted with a front wheel (6) and rotatably connected to the frame body (8) and a fixed The rear wheel shaft (51) is installed with the rear wheel (5) and is rotatably connected with the frame body (8), and the front wheel shaft (61) is separately installed with the front wheel shaft (61) which can rotate in the opposite direction in the axial direction. The first one-way bearing (62) of the axle and the second one-way bearing (63) of the front axle, the first one-way bearing of the rear axle (51) which can be rotated in the opposite direction is installed separately in the axial direction (52) and the second one-way bearing (53) of the rear axle. The front wheel shaft (61) is also provided with a front drive wheel (111), and the front drive wheel (111) is connected with the motor by the front drive belt (211). The drive wheel (101) driven by (100) is power-connected, and the rear wheel shaft (51) is also provided with a rear drive wheel (121).

Owner:俞升洋

Welding car capable of removing dust for continuous welding process

InactiveCN105798499AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

The invention discloses a welding car capable of removing dust for a continuous welding process. The welding car comprises a frame body (8) for bearing a welding gun (9), a front wheel shaft (61) fixedly provided with a front wheel (6) and rotationally connected with the frame body (8), and a rear wheel shaft (51) fixedly provided with a rear wheel (5) and rotationally connected with the frame body (8); a front shaft first one-way bearing (62) and a front shaft second one-way bearing (63), with opposite rotating directions, are mounted in the axial direction of the front wheel shaft (61) at intervals; a back shaft first one-way bearing (52) and a rear shaft second one-way bearing (53), with opposite rotating directions, are mounted in the axial direction of the rear wheel shaft (51) at intervals; a front driving wheel (111) is arranged on the front wheel shaft (61), and is in power connection with a driving wheel (101) driven by a motor (100) through a front conveying belt (211); and a rear driving wheel (121) is arranged on the rear wheel shaft (51).

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

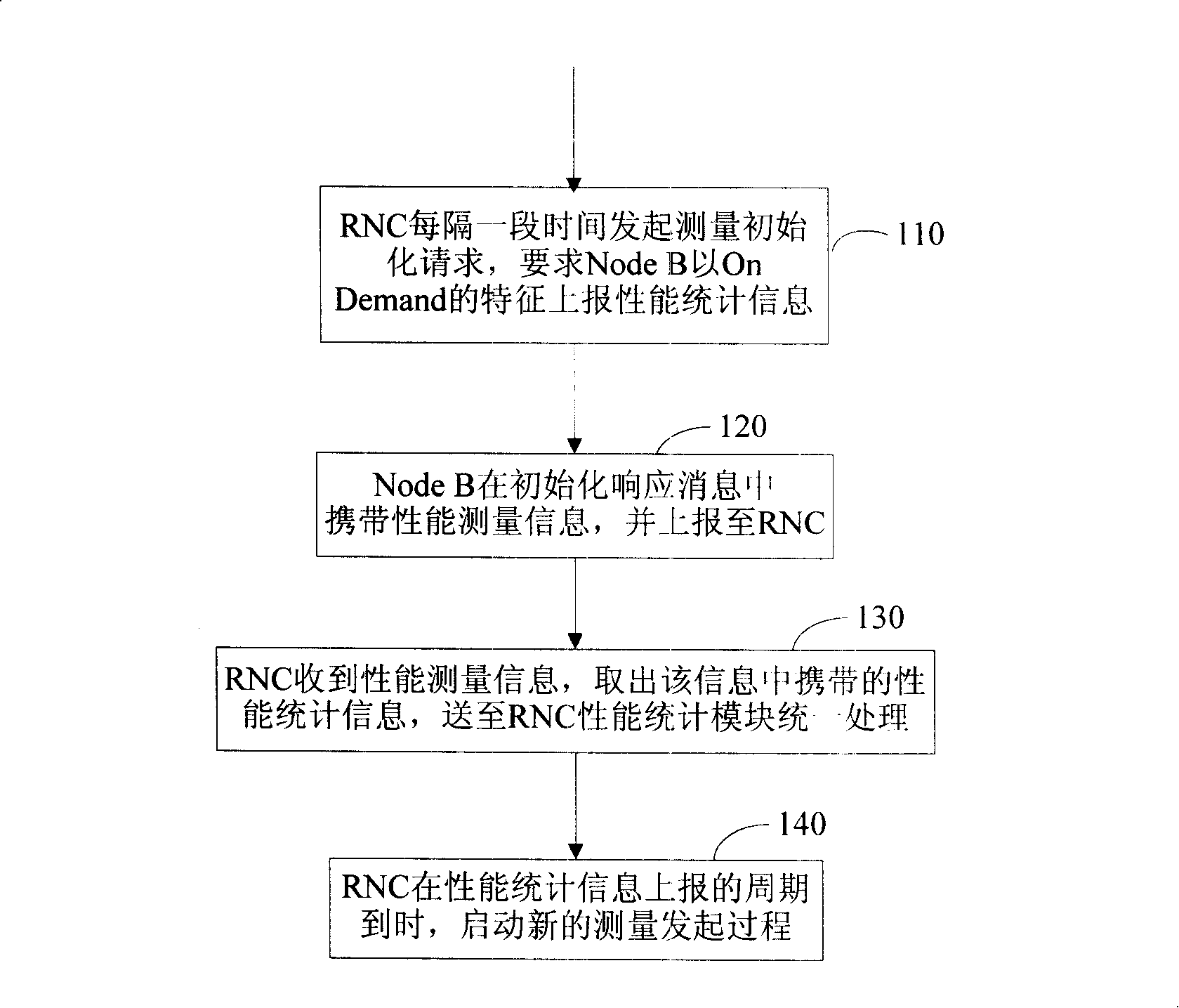

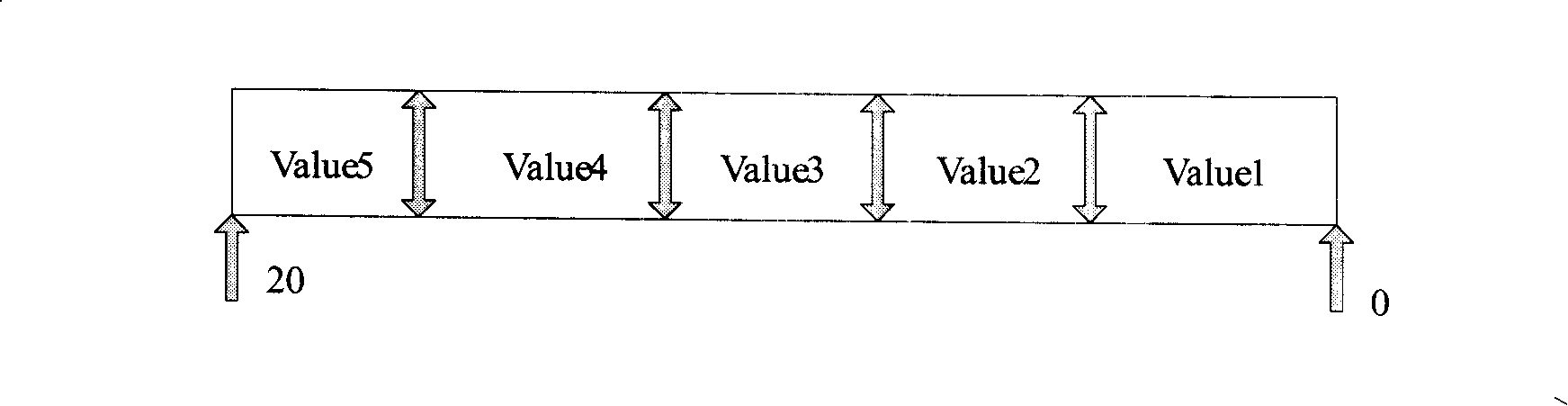

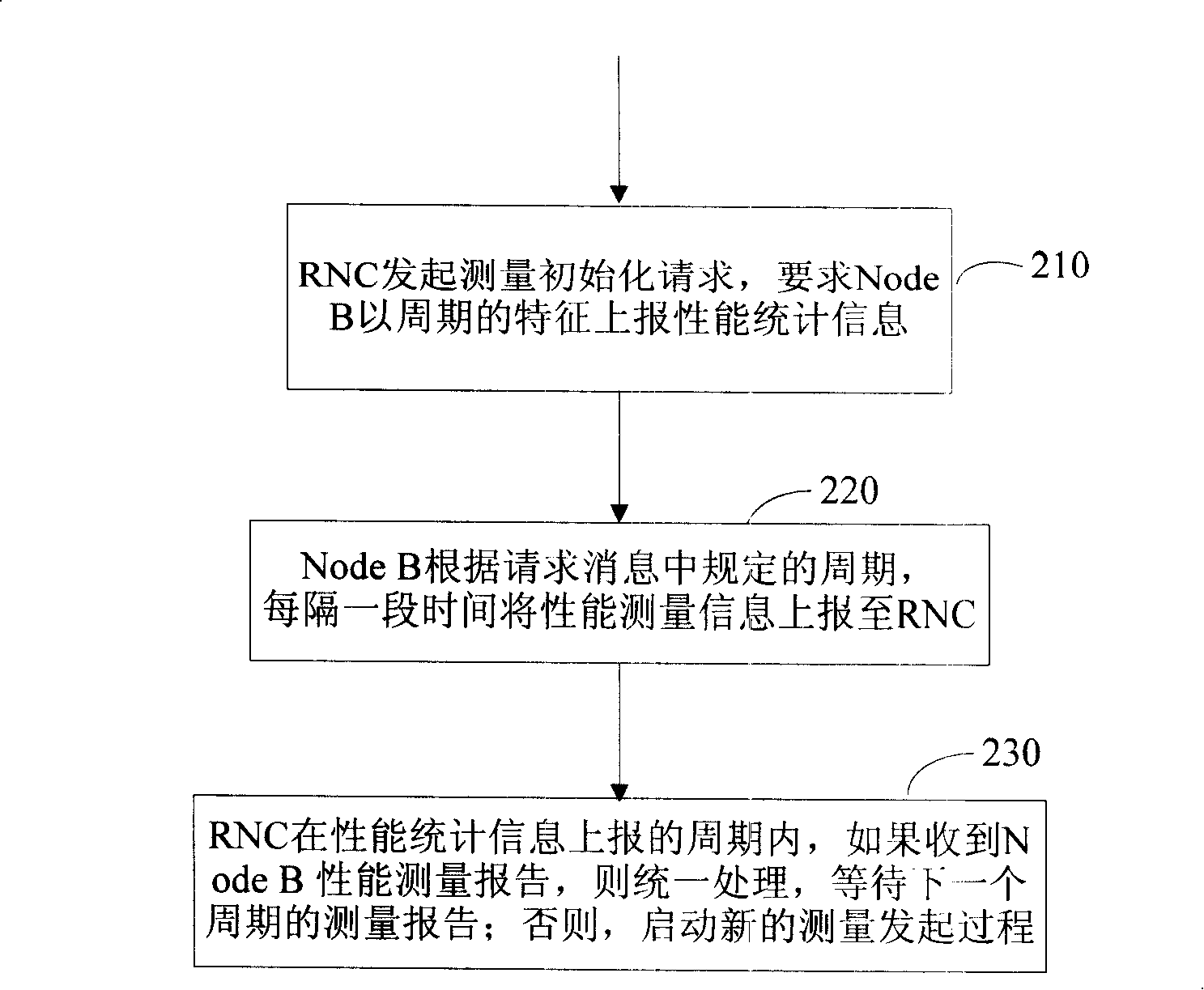

Common measuring method supporting node B performance statistics in WCDMA system

InactiveCN101222724AMeet needsDoes not affect load controlRadio/inductive link selection arrangementsRadio transmission for post communicationCode division multiple accessRadio Network Controller

The invention provides a public measuring method for performance statistics of support node B in a wideband code division multiple access system, which comprises the following steps: (1) after a cell is established on the radio network controller RNC, the cell initiates a TDD public measuring initialization request of a UL Timeslot ISCP type, and a required report mode is specified in the request; (2) the node B receives a message of the measuring initialization request, according to the specified report mode in the request, performance measuring information of the node B is sent to the RNC.

Owner:ZTE CORP

Multifunctional welding tractor

InactiveCN105773020AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesTractorWelding

The invention discloses a multifunctional welding tractor which comprises a tractor frame (8), a front axle (61) and a rear axle (51).The tractor frame (8) is used for bearing a welding fun (9), the front axle (61) is fixedly provided with a front wheel (6) and rotationally connected with the tractor frame (8), and the rear axle (51) is fixedly provided with a rear wheel (5) and rotationally connected with the tractor frame (8).A front axle first one-way bearing (62) and a front axle second one-way bearing (63) in the opposite rotating directions are installed in the axial direction of the front axle (61) in a spaced mode.A rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) in the opposite rotating directions are installed in the axial direction of the rear axle (51) in a spaced mode.The front axle (61) is further provided with a front driving wheel (111).The front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) through a front driving belt (211).The rear axle (51) is further provided with a rear driving wheel (121).

Owner:孙卫香

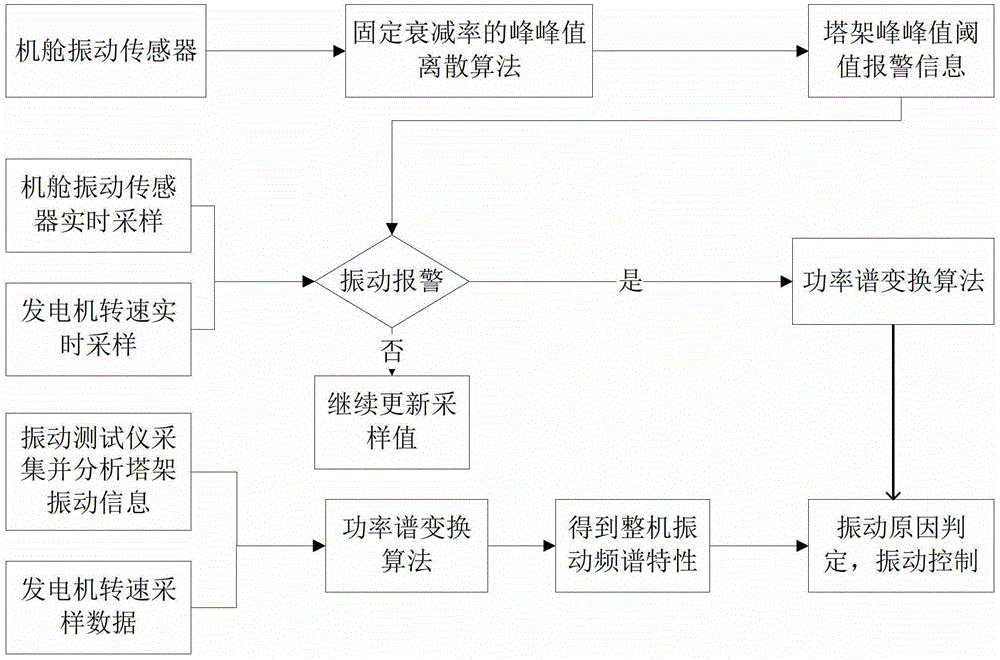

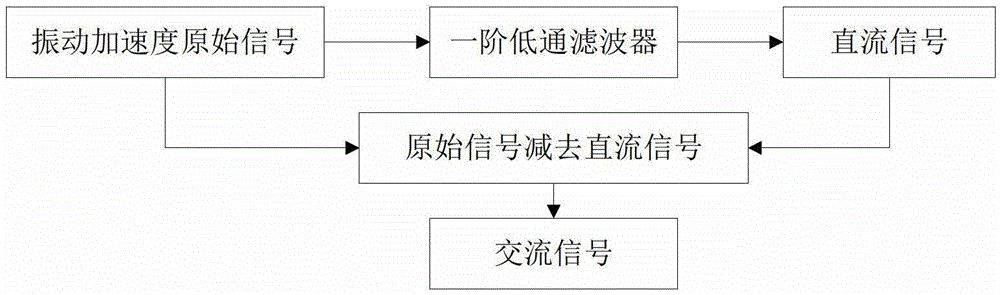

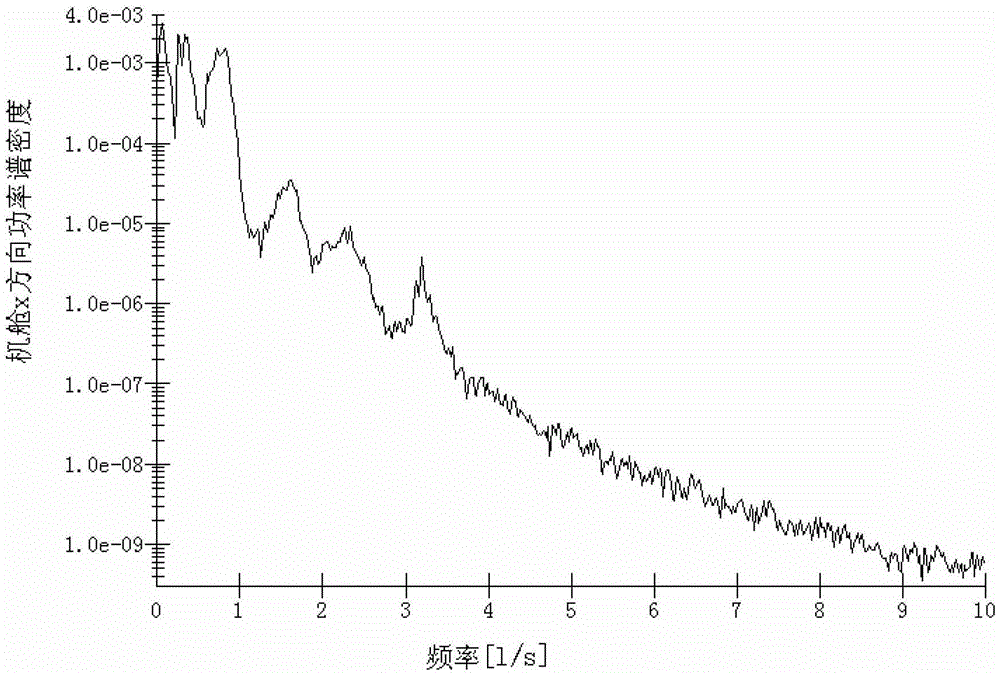

A method for controlling vibration of a tower of a wind power generating set

ActiveCN103321854BAvoid dependencyAvoid instabilityWind motor controlMachines/enginesMachining vibrationsFrequency spectrum

The invention discloses a vibration control method for a wind generator set tower. The method comprises the steps of collecting motor rotation speed data in real time and utilizing a cabin vibration sensor to collect vibration signals; converting the collected vibration signals into vibration signal peak-to-peak values, and when the vibration signal peak-to-peak values exceed a set alarm value, triggering vibration alarm and performing real-time frequency spectrum characteristic analysis; obtaining real-time frequency spectrum characteristics and a wind wheel rotating speed value at the time; comparing a complete machine vibration frequency point corresponding to the wind wheel rotating speed value in complete machine vibration frequency characteristics obtained in advance and energy concentration degree under the frequency in a real-time frequency spectrum characteristic spectrum, and analyzing vibration reasons and correspondingly performing vibration reduction processing according to the different reasons. According to the vibration control method, the reasons for causing complete machine vibration are distinguished through a spectral analysis algorithm, so that cabin vibration of a wind generator is controlled to guarantee complete machine safety, times of shutdown caused by vibration is reduced, and the wind generator set utilization rate is improved.

Owner:STATE GRID CORP OF CHINA +2

Welding carriage powered by solar energy

InactiveCN105817796AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesSolar powerAutomotive engineering

A welding carriage powered by solar energy comprises a frame body (8), a front axle (61) and a rear axle (51), wherein the frame body (8) is used for bearing a welding gun (9); front wheels (6) are fixedly mounted on the front axle (61) which is rotationally connected with the frame body (8); rear wheels (5) are fixedly mounted on the rear axle (51) which is rotationally connected with the frame body (8); a front axle first one-way bearing (62) and a front axle second one-way bearing (63) with opposite rotatable directions are mounted on the front axle (61) in the axial direction in a spaced manner; a rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) with opposite rotatable directions are mounted on the rear axle (51) in the axial direction in a spaced manner; a front drive wheel (111) is arranged on the front axle (61) and is in power connection with a driving wheel (101), driven by a motor, through a front driving belt (211); a rear drive wheel (121) is arranged on the rear axle (51).

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Welding trolley for factory workshop

InactiveCN105965187AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

A welding trolley for a factory workshop comprises a frame body (8) used for bearing a weld gun (9), a front wheel axle (61) and a rear wheel axle (51), wherein the front wheel axle (61) is fixedly provided with a front wheel (6) and rotationally connected with the frame body (8), and the rear wheel axle (51) is fixedly provided with a rear wheel (5) and rotationally connected with the frame body (8). A first front axle one-way bearing (62) and a second front axle one-way bearing (63) are arranged on the front wheel axle (61) in the axial direction in a spaced manner and are opposite in rotation direction. A first rear axle one-way bearing (52) and a second rear axle one-way bearing (53) are arranged on the rear wheel axle (51) in the axial direction in a spaced manner and are opposite in rotation direction. The front wheel axle (61) is further provided with a front drive wheel (111). The front drive wheel (111) is in power connection with a drive wheel (101) through a front transmission belt (211), wherein the drive wheel (101) is driven by a motor (100). The rear wheel axle (51) is further provided with a rear drive wheel (121).

Owner:俞升洋

Welding car for contact warning

ActiveCN105945473AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheel

The invention discloses a welding car for contact warning. The welding car for contact warning comprises a car frame body (8) for bearing a welding gun (9), a front wheel shaft (61) fixed with a front wheel (6) and rotationally connected with the car frame body (8), and a back wheel shaft (51) fixed with a back wheel (5) and rotationally connected with the car frame body (8); a front shaft first one-way bearing (62) and a front shaft second one-way bearing (63) with opposite rotating directions are spaced in the axial direction of the front wheel shaft (61); a back shaft first one-way bearing (52) and a back shaft second one-way bearing (53) with opposite rotating directions are spaced in the axial direction of the back wheel shaft (51); a front driving wheel (111) is arranged on the front wheel shaft (61), and is in power connection with a driving wheel (101) driven by a motor (100) through a front conveying belt (211); and a back driving wheel (121) is arranged on the back wheel shaft (51).

Owner:宁波协顺机电有限公司

Industrial welding device

InactiveCN106002016AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelWelding

The invention relates to an industrial welding device which comprises a frame body (8) used for bearing a welding gun (9), a front axle (61) which is fixedly provided with a front wheel (6) and rotatably connected with the frame body (8) and a rear axle (51) which is fixedly provided with a rear wheel (5) and rotatably connected with the frame body (8), wherein a front axle first unidirectional bearing (62) and a front axle second unidirectional bearing (63) with opposite rotation directions are arranged in the axial direction of the front axle (61) at an intervals, a rear axle first unidirectional bearing (52) and a rear axle second unidirectional bearing (53) with opposite rotation directions are arranged in the axial direction of the rear axle (51) at an interval, a front driving wheel (111) is arranged on the front axle (61), the front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) by a front driving belt (211), and a rear driving wheel (121) is arranged on the rear axle (51).

Owner:俞升洋

Speed-adjustable welding car for continuous welding process

InactiveCN106002021AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive wheel

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Welding car convenient for use

InactiveCN105945472AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

The invention discloses a welding car convenient for use. The welding car convenient for use comprises a car frame body (8) for bearing a welding gun (9), a front wheel shaft (61) fixed with a front wheel (6) and rotationally connected with the car frame body (8), and a back wheel shaft (51) fixed with a back wheel (5) and rotationally connected with the car frame body (8); a front shaft first one-way bearing (62) and a front shaft second one-way bearing (63) with opposite rotating directions are spaced in the axial direction of the front wheel shaft (61); a back shaft first one-way bearing (52) and a back shaft second one-way bearing (53) with opposite rotating directions are spaced in the axial direction of the back wheel shaft (51); a front driving wheel (111) is arranged on the front wheel shaft (61), and is in power connection with a driving wheel (101) driven by a motor (100) through a front conveying belt (211); and a back driving wheel (121) is arranged on the back wheel shaft (51).

Owner:孙卫香

Welding trolley

ActiveCN105773021AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheel

A welding trolley comprises a frame body (8) for bearing a welding gun (9), a front axle (61) fixedly provided with front wheels (6) and rotationally connected with the frame body (8), and a rear axle (51) fixedly provided with rear wheels (5) and rotationally connected with the frame body (8).A front axle first one-way bearing (62) and a front axle second one-way bearing (63) with opposite rotational directions are axially and separately installed on the front axle (61).A rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) with opposite rotational directions are axially and separately installed on the rear axle (51).A front driving wheel (111) is further arranged on the front axle (61) and is in power connection with a driving wheel (101) driven by a motor (100) through a front transmission belt (211).A rear driving wheel (121) is further arranged on the rear axle (51).

Owner:湖州佳灏信息技术有限公司

Solar power supply mobile welding tractor

InactiveCN106002017AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesTractorSolar power

The invention relates to a solar power supply mobile welding tractor which comprises a frame body (8) used for bearing a welding gun (9), a front axle (61) which is fixedly provided with a front wheel (6) and rotatably connected with the frame body (8) and a rear axle (51) which is fixedly provided with a rear wheel (5) and rotatably connected with the frame body (8), wherein a front axle first unidirectional bearing (62) and a front axle second unidirectional bearing (63) with opposite rotation directions are arranged in the axial direction of the front axle (61) at an intervals, a rear axle first unidirectional bearing (52) and a rear axle second unidirectional bearing (53) with opposite rotation directions are arranged in the axial direction of the rear axle (51) at an interval, a front driving wheel (111) is arranged on the front axle (61), the front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) by a front driving belt (211), and a rear driving wheel (121) is arranged on the rear axle (51).

Owner:俞升洋

An industrial welding trolley

ActiveCN106002020BReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTractor

The invention relates to an industrial welding tractor which comprises a frame body (8) used for bearing a welding gun (9), a front axle (61) which is fixedly provided with a front wheel (6) and rotatably connected with the frame body (8) and a rear axle (51) which is fixedly provided with a rear wheel (5) and rotatably connected with the frame body (8), wherein a front axle first unidirectional bearing (62) and a front axle second unidirectional bearing (63) with opposite rotation directions are arranged in the axial direction of the front axle (61) at an intervals, a rear axle first unidirectional bearing (52) and a rear axle second unidirectional bearing (53) with opposite rotation directions are arranged in the axial direction of the rear axle (51) at an interval, a front driving wheel (111) is arranged on the front axle (61), the front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) by a front driving belt (211), and a rear driving wheel (121) is arranged on the rear axle (51).

Owner:泰安智慧谷产业园运营管理有限公司

A welding trolley with contact alarm

ActiveCN105945473BReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

The invention discloses a welding car for contact warning. The welding car for contact warning comprises a car frame body (8) for bearing a welding gun (9), a front wheel shaft (61) fixed with a front wheel (6) and rotationally connected with the car frame body (8), and a back wheel shaft (51) fixed with a back wheel (5) and rotationally connected with the car frame body (8); a front shaft first one-way bearing (62) and a front shaft second one-way bearing (63) with opposite rotating directions are spaced in the axial direction of the front wheel shaft (61); a back shaft first one-way bearing (52) and a back shaft second one-way bearing (53) with opposite rotating directions are spaced in the axial direction of the back wheel shaft (51); a front driving wheel (111) is arranged on the front wheel shaft (61), and is in power connection with a driving wheel (101) driven by a motor (100) through a front conveying belt (211); and a back driving wheel (121) is arranged on the back wheel shaft (51).

Owner:宁波协顺机电有限公司

Welding tractor used for continuous welding process and capable of increasing friction

InactiveCN105798503AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTransmission belt

The invention relates to a welding tractor used for a continuous welding process and capable of increasing friction. The welding tractor comprises a tractor frame body (8) used for bearing a welding gun (9), a front axle (61) fixedly provided with front wheels (6) and rotationally connected with the tractor frame body (8) and a back axle (51) fixedly provided with back wheels (5) and rotationally connected with the tractor frame body (8); a first front axle one-way bearing (62) and a second front axle one-way bearing (63) which are opposite in rotation direction are arranged on the front axle (61) in a spaced manner in the axial direction, and a first back axle one-way bearing (52) and a second back axle one-way bearing (53) which are opposite in rotation direction are arranged on the back axle (51) in a spaced manner in the axial direction; the front axle (61) is further provided with a front driving wheel (111) which is in power connection with a driving wheel (101) driven by a motor (100) through a front transmission belt (211); and the back axle (51) is further provided with a back driving wheel (121).

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

A welding trolley

ActiveCN105773021BReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheel

A welding trolley comprises a frame body (8) for bearing a welding gun (9), a front axle (61) fixedly provided with front wheels (6) and rotationally connected with the frame body (8), and a rear axle (51) fixedly provided with rear wheels (5) and rotationally connected with the frame body (8).A front axle first one-way bearing (62) and a front axle second one-way bearing (63) with opposite rotational directions are axially and separately installed on the front axle (61).A rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) with opposite rotational directions are axially and separately installed on the rear axle (51).A front driving wheel (111) is further arranged on the front axle (61) and is in power connection with a driving wheel (101) driven by a motor (100) through a front transmission belt (211).A rear driving wheel (121) is further arranged on the rear axle (51).

Owner:湖州佳灏信息技术有限公司

Welding seam welding vehicle

InactiveCN105965188AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesWeld seamSeam welding

A welding seam welding vehicle comprises a frame body (8) for carrying a welding gun (9), a front wheel axle (61) and a rear wheel axle (51), wherein a front wheel (6) is fixedly mounted on the front wheel axle (61), and the front wheel axle (61) is rotationally connected with the frame body (8); a rear wheel (5) is fixedly mounted on the rear wheel axle (51), and the rear wheel axle (51) is rotationally connected with the frame body (8); a front axle first one-way bearing (62) and a front axle second one-way bearing (63) which rotate in the opposite direction are mounted on the front wheel axle (61) in the axial direction in a spaced manner; a rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) which rotate in the opposite direction are mounted on the rear wheel axle (51) in the axial direction in a spaced manner; a front driving wheel (111) is further arranged on the front wheel axle (61) and is in power connection with a driving wheel (101) driven by a motor (100) by the aid of a front transmission belt (211); and a rear driving wheel (121) is further arranged on the rear wheel axle (51).

Owner:俞升洋

Welding tractor for continuously welding weld joint

InactiveCN105773018AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelWeld seam

The invention discloses a welding tractor for continuously welding a weld joint.The welding tractor comprises a tractor frame (8), a front axle (61) and a rear axle (51).The tractor frame (8) is used for bearing a welding fun (9), the front axle (61) is fixedly provided with a front wheel (6) and rotationally connected with the tractor frame (8), and the rear axle (51) is fixedly provided with a rear wheel (5) and rotationally connected with the tractor frame (8).A front axle first one-way bearing (62) and a front axle second one-way bearing (63) in the opposite rotating directions are installed in the axial direction of the front axle (61) in a spaced mode.A rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) in the opposite rotating directions are installed in the axial direction of the rear axle (51) in a spaced mode.The front axle (61) is further provided with a front driving wheel (111).The front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) through a front driving belt (211).The rear axle (51) is further provided with a rear driving wheel (121).

Owner:俞升洋

Adjustable welding tractor

InactiveCN105773019AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTransmission belt

An adjustable welding tractor comprises a tractor frame body (8) for bearing a welding gun (9), a front wheel axle (61) fixedly provided with front wheels (6) and rotationally connected with the tractor frame body (8), and a rear wheel axle (51) fixedly provided with rear wheels (5) and rotationally connected with the tractor frame body (8).A first front wheel axle one-way bearing (62) and a second front wheel axle one-way bearing (63) with opposite rotational directions are installed in the axial direction of the front wheel axle (61) in a spaced mode.A first rear wheel axle one-way bearing (52) and a second rear wheel axle one-way bearing (53) with opposite rotational directions are installed in the axial direction of the rear wheel axle (51) in a spaced mode.A front drive wheel (111) is further arranged on the front wheel axle (61) and is in power connection with a driving wheel (101) driven by a motor (100) through a front transmission belt (211).A rear drive wheel (121) is further arranged on the rear wheel axle (51).

Owner:孙卫香

Welding tractor used for continuous welding process

InactiveCN105798504AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesTransmission beltEngineering

The invention relates to a welding tractor used for a continuous welding process. The welding tractor comprises a tractor frame body (8) used for bearing a welding gun (9), a front axle (61) fixedly provided with front wheels (6) and rotationally connected with the tractor frame body (8) and a back axle (51) fixedly provided with back wheels (5) and rotationally connected with the tractor frame body (8); a first front axle one-way bearing (62) and a second front axle one-way bearing (63) which are opposite in rotation direction are arranged on the front axle (61) in a spaced manner in the axial direction, and a first back axle one-way bearing (52) and a second back axle one-way bearing (53) which are opposite in rotation direction are arranged on the back axle (51) in a spaced manner in the axial direction; the front axle (61) is further provided with a front driving wheel (111) which is in power connection with a driving wheel (101) driven by a motor (100) through a front transmission belt (211); and the back axle (51) is further provided with a back driving wheel (121).

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Industrial welding tractor

ActiveCN106002020AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesTractorWelding

The invention relates to an industrial welding tractor which comprises a frame body (8) used for bearing a welding gun (9), a front axle (61) which is fixedly provided with a front wheel (6) and rotatably connected with the frame body (8) and a rear axle (51) which is fixedly provided with a rear wheel (5) and rotatably connected with the frame body (8), wherein a front axle first unidirectional bearing (62) and a front axle second unidirectional bearing (63) with opposite rotation directions are arranged in the axial direction of the front axle (61) at an intervals, a rear axle first unidirectional bearing (52) and a rear axle second unidirectional bearing (53) with opposite rotation directions are arranged in the axial direction of the rear axle (51) at an interval, a front driving wheel (111) is arranged on the front axle (61), the front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) by a front driving belt (211), and a rear driving wheel (121) is arranged on the rear axle (51).

Owner:泰安智慧谷产业园运营管理有限公司

Solar welding carriage

InactiveCN105855768AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTransmission belt

The invention provides a solar welding carriage. The solar welding carriage comprises a frame body (8), a front axle (61) and a rear axle (51), wherein the frame body is used for bearing a welding gun (9); a front wheel (6) is fixedly installed on the front axle, and the front axle is connected with the frame body (8) in a rotatable manner; a rear wheel (5) is fixedly installed on the rear axle, and the rear axle is connected with the frame body (8) in a rotatable manner; a front axle first one-way bearing (62) and a front axle second one-way bearing (63), which have opposite rotatable directions, are installed on the front axle (61) in the axial direction at intervals; a rear axle first one-way bearing (52) and a rear axle second one-way bearing (53), which have opposite rotatable directions, are installed on the rear axle (51) in the axial direction at intervals; a front driving wheel (111) is also arranged on the front axle (61) and is in power connection with a drive wheel (101) driven by a motor (100) via a front transmission belt (211); and a rear driving wheel (121) is also arranged on the rear axle (51).

Owner:俞升洋

Novel welding tractor

InactiveCN105904120AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

The invention discloses a novel welding tractor. The novel welding tractor comprises a tractor frame body (8) used for bearing a weld gun (9), a front wheel shaft (61) which is fixedly equipped with a front wheel (6) and is rotatably connected with the tractor frame body (8), and a back wheel shaft (51) which is fixedly equipped with a back wheel (5) and is rotatably connected with the tractor frame body (8), wherein a front shaft first one-way bearing (62) and a front shaft second one-way bearing (63) with reverse rotation directions are mounted on the front wheel shaft (61) at intervals in the axial direction; a back shaft first one-way bearing (52) and a back shaft second one-way bearing (53) with reverse rotation directions are mounted on the back wheel shaft (51) at intervals in the axial direction; a front driving wheel (111) is further arranged on the front wheel shaft (61); the front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) through a front driving belt (211); and a back driving wheel (121) is further arranged on the back wheel shaft (51).

Owner:孙卫香

Welding carriage control system for continuous welding technology

InactiveCN105817803AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelControl system

A welding carriage control system for a continuous welding technology comprises a DSP controller, a motor drive circuit and a welding carriage, wherein the welding carriage comprises a frame body (8), a front axle (61) and a rear axle (51); the frame body (8) is used for bearing a welding gun (9); front wheels (6) are fixedly mounted on the front axle (61) which is rotationally connected with the frame body (8); rear wheels (5) are fixedly mounted on the rear axle (51) which is rotationally connected with the frame body (8); a front axle first one-way bearing (62) and a front axle second one-way bearing (63) with opposite rotatable directions are mounted on the front axle (61) in the axial direction in a spaced manner; a rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) with opposite rotatable directions are mounted on the rear axle (51) in the axial direction in a spaced manner; a front drive wheel (111) is arranged on the front axle (61) and is in power connection with a driving wheel (101), driven by a motor, through a front driving belt (211); a rear drive wheel (121) is arranged on the rear axle (51).

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Movable welding tractor

InactiveCN105817799AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelEngineering

The invention discloses a movable welding tractor. The movable welding tractor comprises a frame body (8) for bearing a welding gun (9), a front wheel axle (61) and a rear wheel axle (51), wherein the front wheel axle (61) is fixedly provided with a front wheel (6) and is rotationally connected with the frame body (8); the rear wheel axle (51) is fixedly provided with a rear wheel (5) and is rotationally connected with the frame body (8); a front axle first one-way bearing (62) and a front axle second one-way bearing (63) of which rotational directions are opposite to each other are arranged in the axial direction of the front wheel axle (61) in a spacing way; a rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) of which rotational directions are opposite to each other are arranged in the axial direction of the rear wheel axle (51) in a spacing way; a front driving wheel (111) is also arranged on the front wheel axle (61) and is in powered connection with a driving wheel (101) driven by a motor (100) through a front conveying belt (211); and a rear driving wheel (121) is also arranged on the rear wheel axle (51).

Owner:俞升洋

Welding device for continuous welding technology

InactiveCN105773022AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTransmission belt

A welding device for a continuous welding technology comprises a frame body (8) for bearing a welding gun (9), a front wheel axle (61) fixedly provided with a front wheels (6) and rotationally connected with the frame body (8), and a rear wheel axle (51) fixedly provided with rear wheels (5) and rotationally connected with the frame body (8).A first front axle one-way bearing (62) and a second front axle one-way bearing (63) with the opposite rotational directions are installed on the front wheel axle (61) in the axial direction in a spaced mode.A first rear axle one-way bearing (52) and a second rear axle one-way bearing (53) with the opposite rotational directions are installed on the rear wheel axle (51) in the axial direction in a space mode.A front drive wheel (111) is further arranged on the front wheel axle (61) and is in power connection with a driving wheel (101) through a front transmission belt (211), wherein the driving wheel (101) is driven by a motor (100).A rear drive wheel (121) is further arranged on the rear wheel axle (51).

Owner:尚庆光

Welding seam welding vehicle

InactiveCN105921920AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelVehicle frame

The invention provides a welding seam welding vehicle. The welding seam welding vehicle comprises a vehicle frame body (8), a front wheel shaft (61) and a back wheel shaft (51), wherein the vehicle frame body (8) is used for bearing a welding gun (9); a front wheel (6) is fixedly installed on the front wheel shaft (61), and the front wheel shaft (61) is rotationally connected with the vehicle frame body (8); and a back wheel (6) is fixedly installed on the back wheel shaft (61), and the back wheel shaft (61) is rotationally connected with the vehicle frame body (8). A first front shaft one-way bearing (62) and a second front shaft one-way bearing (63) which are opposite in rotatable direction are installed in the axial direction of the front wheel shaft (61) in a spaced mode. A first back shaft one-way bearing (52) and a second back shaft one-way bearing (53) which are opposite in rotatable direction are installed in the axial direction of the back wheel shaft (51) in a spaced mode. The front wheel shaft (61) is further provided with a front driving wheel (111). The front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) through a front conveying belt (211). The back wheel shaft (51) is further provided with a back driving wheel (121).

Owner:俞升洋

Welding carriage with efficient heat dissipation function

InactiveCN105817802AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesAutomotive engineeringEngineering

A welding carriage with an efficient heat dissipation function comprises a frame body (8), a front axle (61) and a rear axle (51), wherein the frame body (8) is used for bearing a welding gun (9); front wheels (6) are fixedly mounted on the front axle (61) which is rotationally connected with the frame body (8); rear wheels (5) are fixedly mounted on the rear axle (51) which is rotationally connected with the frame body (8); a front axle first one-way bearing (62) and a front axle second one-way bearing (63) with opposite rotatable directions are mounted on the front axle (61) in the axial direction in a spaced manner; a rear axle first one-way bearing (52) and a rear axle second one-way bearing (53) with opposite rotatable directions are mounted on the rear axle (51) in the axial direction in a spaced manner; a front drive wheel (111) is arranged on the front axle (61) and is in power connection with a driving wheel (101), driven by a motor, through a front driving belt (211); a rear drive wheel (121) is arranged on the rear axle (51).

Owner:XIAOGAN BUJI ELECTRONICS COMMERCE CO LTD

Durable welding tractor

InactiveCN106002018AReduce lossDoes not affect power controlWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTractor

The invention relates to a durable welding tractor which comprises a frame body (8) used for bearing a welding gun (9), a front axle (61) which is fixedly provided with a front wheel (6) and rotatably connected with the frame body (8) and a rear axle (51) which is fixedly provided with a rear wheel (5) and rotatably connected with the frame body (8), wherein a front axle first unidirectional bearing (62) and a front axle second unidirectional bearing (63) with opposite rotation directions are arranged in the axial direction of the front axle (61) at an intervals, a rear axle first unidirectional bearing (52) and a rear axle second unidirectional bearing (53) with opposite rotation directions are arranged in the axial direction of the rear axle (51) at an interval, a front driving wheel (111) is arranged on the front axle (61), the front driving wheel (111) is in power connection with a driving wheel (101) driven by a motor (100) by a front driving belt (211), and a rear driving wheel (121) is arranged on the rear axle (51).

Owner:俞升洋

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com