A multifunctional stepless pressure changing device and abs combined relay valve

A technology of a voltage transformer and a relay valve is applied in the field of ABS combined relay valve and multi-functional stepless voltage transformer, which can solve the problems of prolonged braking time, hidden danger of traffic safety, slow braking response speed, etc. Brake control function, the effect of improving braking sensitivity and shortening braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

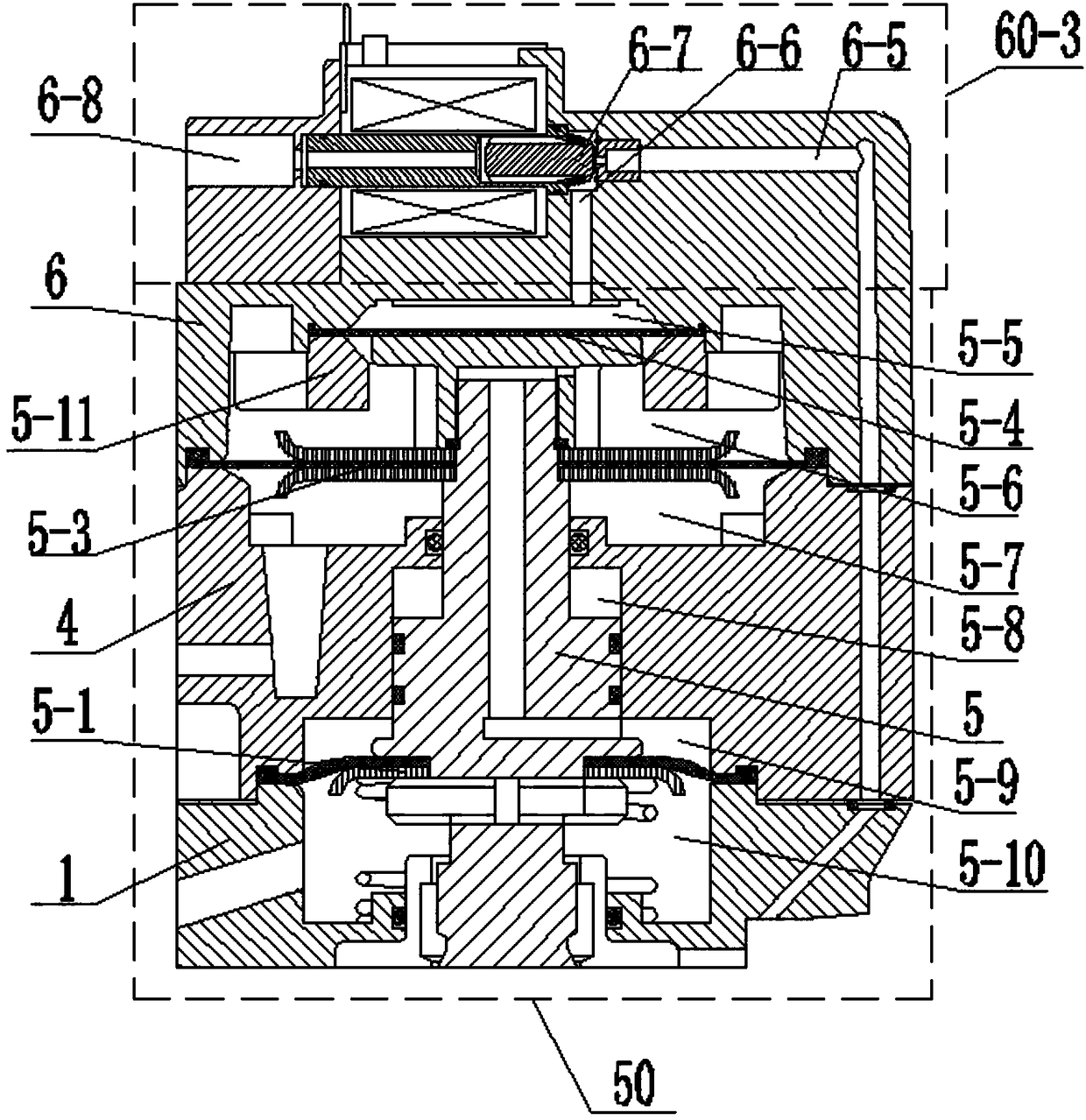

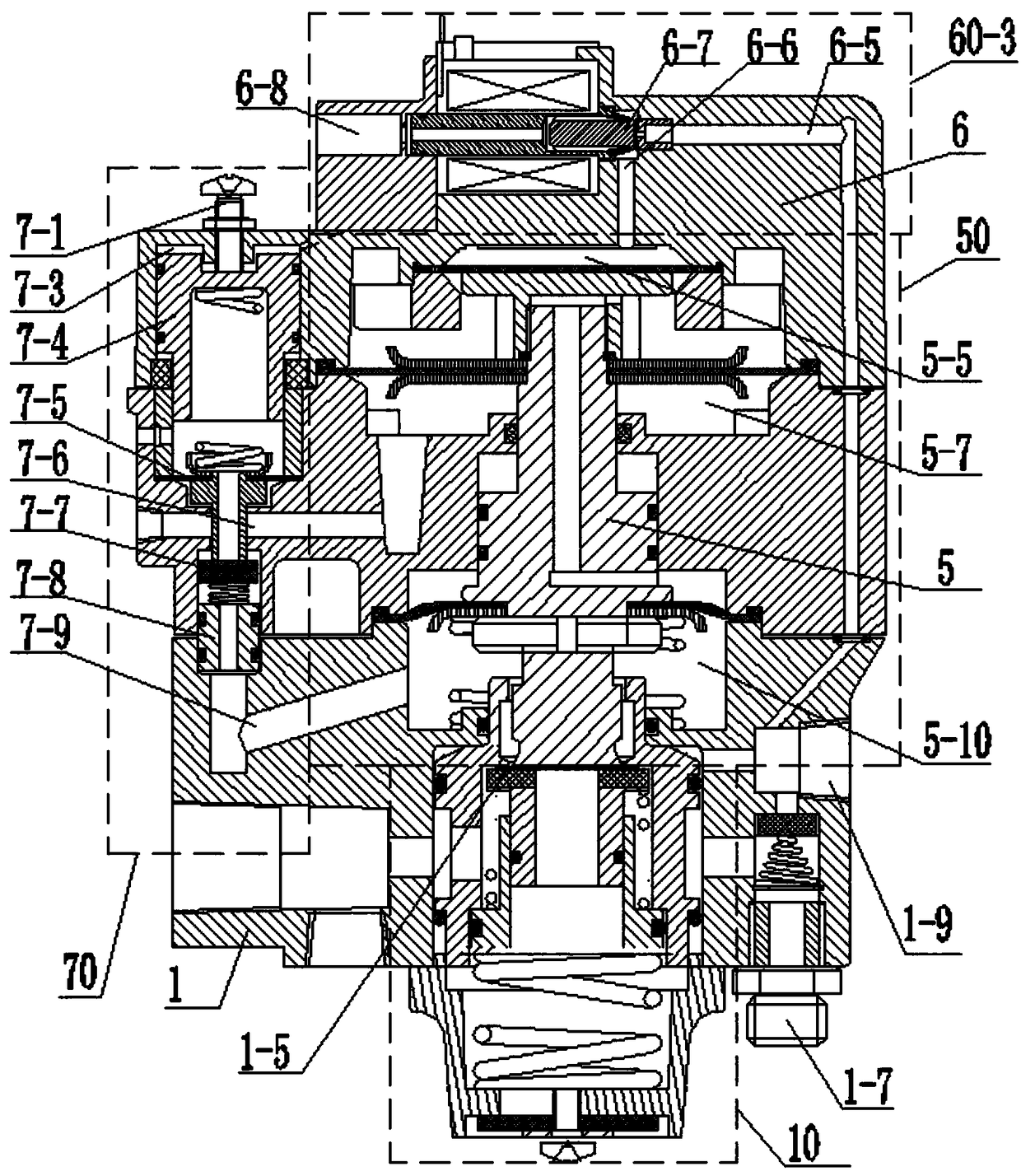

[0068] See figure 2 : figure 2 It is a cross-sectional view of an ABS combined relay valve including a multifunctional stepless pressure changing device, showing the multifunctional stepless pressure changing device, the switch assembly 10, the voltage stabilizing and regulating device 70, and the position and installation relationship of each part.

[0069] Depend on figure 1 It can be seen that the lower end surface of the main valve stem 5 of the multi-functional stepless pressure changing device is in contact with the valve 1-5 of the switch assembly 10, the passage 6-5 in front of the valve is connected with the normally open air inlet 1-9, and the normally open air inlet The air holes 1-9 are externally connected to the air storage tank of the main vehicle; the voltage stabilizing and regulating device 70 is connected in series between the two negative pressure chambers of the multifunctional stepless voltage changing device.

[0070] The specific structure of the sw...

Embodiment 2

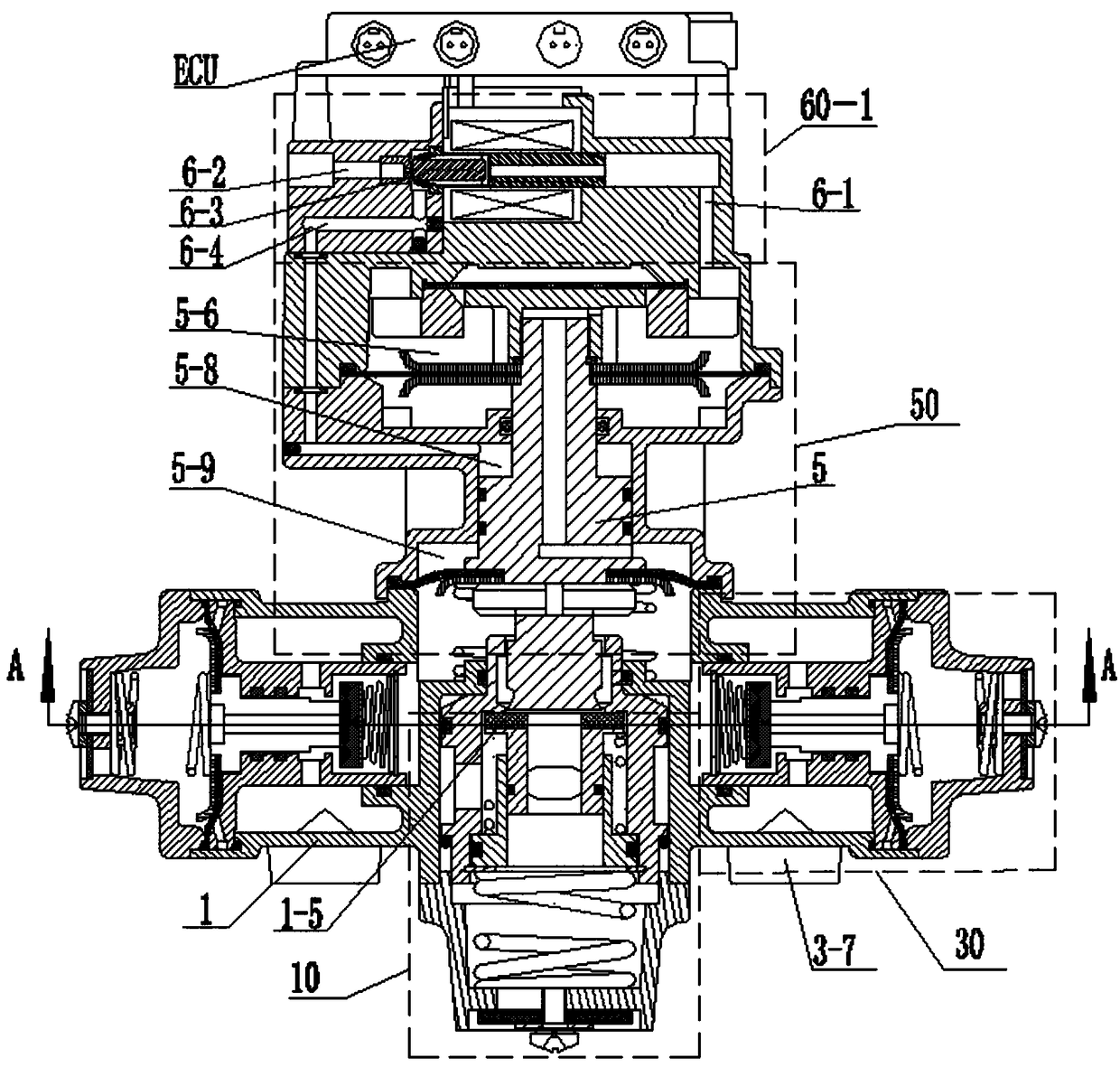

[0076] See image 3 , on the above-mentioned ABS combination relay valve, a first-level anti-locking response device 60 - 1 can also be added, and this device is arranged on the upper cover 6 .

[0077] The first-stage anti-lock braking response device 60-1 of this embodiment includes a pre-valve channel 6-1 communicated with the first working chamber 5-6, and a post-valve channel 6 communicated with the third working chamber 5-8. -4, the pressure relief hole 6-2 directly leading to the atmosphere; a normally closed solenoid valve 6-3 is connected in series between the pressure relief hole 6-2 and the valve front passage 6-1 and the valve rear passage 6-4, and the solenoid valve 6- 3. Controlled by the ECU in the ABS, it controls the communication or isolation of the channel 6-1 before the valve, the channel 6-4 after the valve and the pressure relief hole 6-2. In the ECU control unit of ABS, a first-level anti-lock braking system is added. The system controls the solenoid v...

Embodiment 3

[0083] See Figure 4 , on the above-mentioned ABS combination relay valve, an input air pressure configuration pressure adjustment response device 60 - 2 can also be added, and this device is arranged on the upper cover 6 in this embodiment.

[0084]Input air pressure configuration pressure adjustment response device 60-2 includes control air inlet hole 6-10, control air pressure channel 6-9, configuration valve 6-11, valve stem 6-12, configuration valve diaphragm 6-14, valve front channel 6-13, solenoid valve 6-16, upper valve rear passage 6-15, lower valve rear passage 7-2; among them, control air pressure passage 6-9 and valve front passage 6-13 and first working chamber 5-6 The channel 7-2 after the lower valve communicates with the upper chamber 7-3 of the pressure stabilizing valve of the pressure stabilizing and regulating device 70; the solenoid valve 6-16 is controlled by the ECU in the ABS. In the ECU control unit of ABS, a secondary anti-lock braking system is adde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap