A kind of immobilization method of enzyme

An enzyme immobilization and immobilization time technology, applied in the field of bioengineering, can solve the problems of loss of enzyme activity, limitation of three-dimensional conformation flexibility, and increase of cell immobilization cost, and achieve the effect of improving enzyme activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Add 0.9ml of CaCl with a concentration of 0.2mol / L to 45ml of ALDC with a concentration of 1.2mg / ml in PBS (4mmol / L, pH=7.4) buffer solution 2 In the solution, react at 25°C for 12 hours, centrifuge at 12000rpm for 10min, and wash three times with distilled water to obtain Ca 3 (PO 4 ) 2 – ALDC nanoflowers.

[0045] (2) Calculating the supernatant obtained in step (1) and the enzyme content in the washing liquid with a UV-visible spectrophotometer can obtain Ca 3 (PO 4 ) 2 – Enzyme loading on ALDC nanoflowers is 1.9 mg / Ca 3 (PO 4 ) 2 (1 mg). The nanoflowers loaded with 17 mg of ALDC enzyme were dispersed in 10 ml of 0.03 mol / L sodium alginate solution, and stirred for 1 hour to obtain a uniform dispersion.

[0046] (3) The concentration of 100ml of the dispersion obtained in step (2) is 2.0mol / L CaCl dripped into 100ml with a syringe at a speed of 3ml / min. 2 solution, stirred and solidified for 15 min, centrifuged and washed three times with distilled wate...

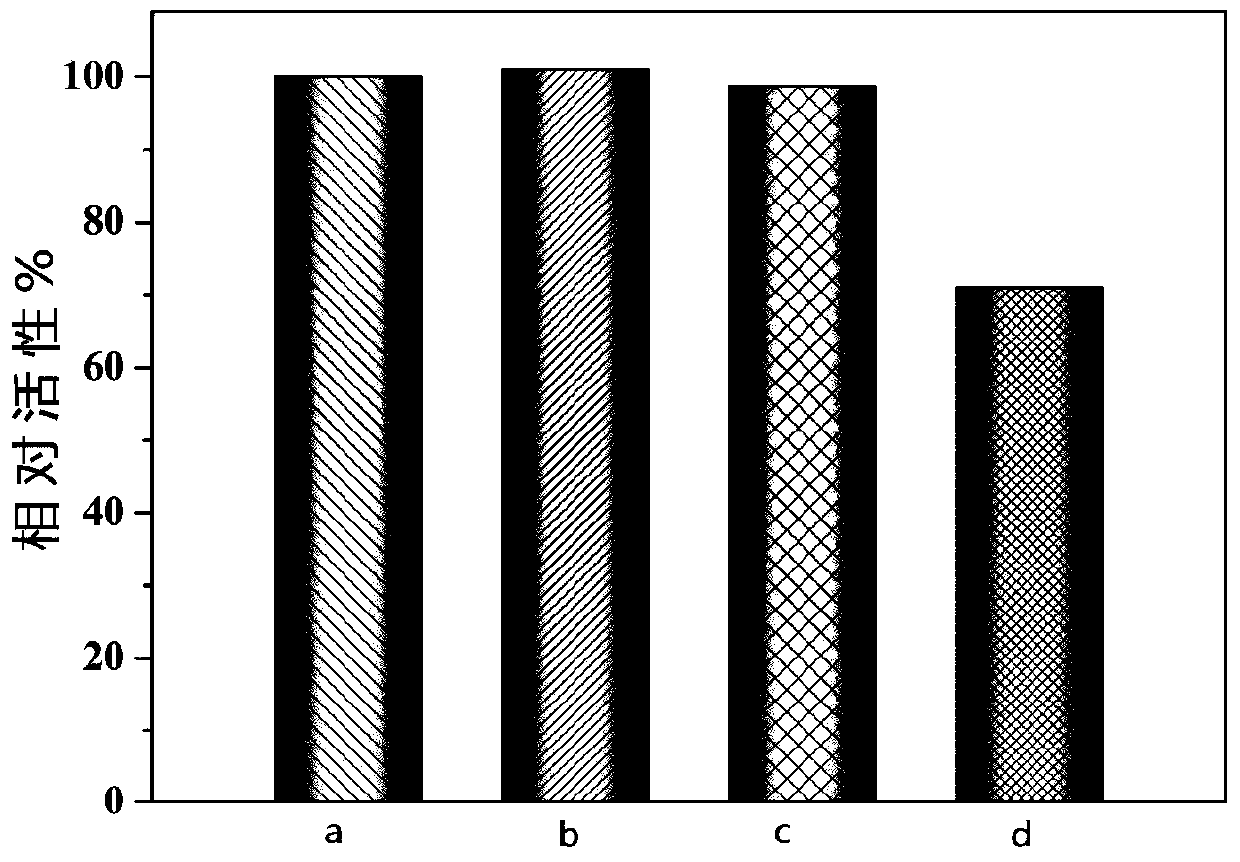

Embodiment 2

[0050] Except that the concentration of ALDC in the PBS (4 mmol / L, pH=7.4) buffer solution of ALDC in step (1) is set to 0 mg / ml, that is, ALDC is not included, the calcium alginate coating is prepared according to the same method as in Example 1 Ca 3 (PO 4 ) 2 Nanoflower microspheres.

Embodiment 3

[0052] Except that the concentration of ALDC in the PBS (4 mmol / L, pH=7.4) buffer of ALDC in step (1) was set to 0.05 mg / ml, the calcium alginate-coated Ca 3 (PO 4 ) 2 – ALDC nanoflower microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com