Multi-core core-spun yarn and double-twist yarn and core-spun yarn thereof, and glove and fabric woven with the multi-core core-spun yarn

A core yarn and core-wrapped technology, which is applied in the field of core-spun yarn and its woven gloves and fabrics, multi-core core-spun yarn and its two-fold twisted yarn, can solve potential safety hazards, affect product strength and comfort, Reduced service life and other issues, achieve good flex resistance, improve stiffness, improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

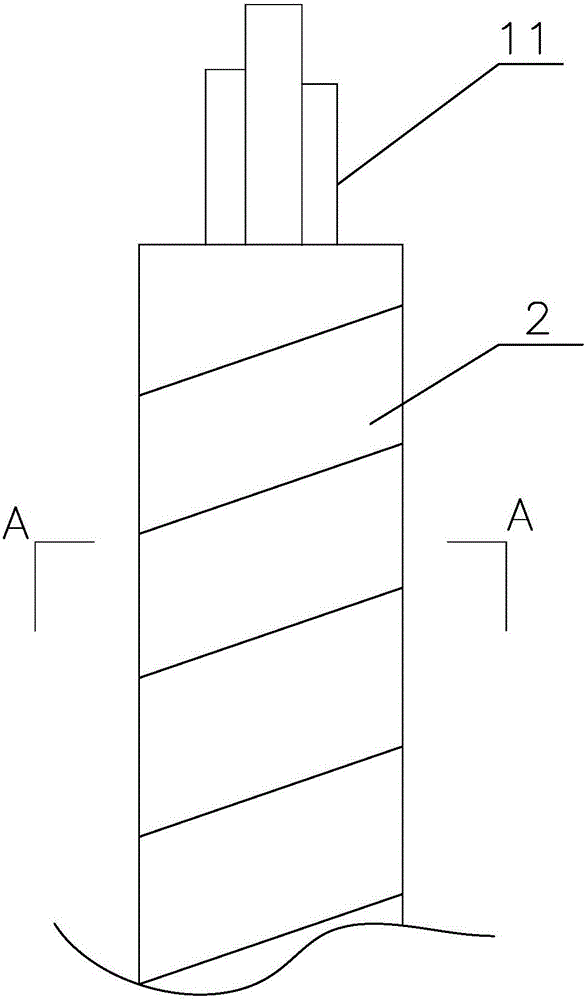

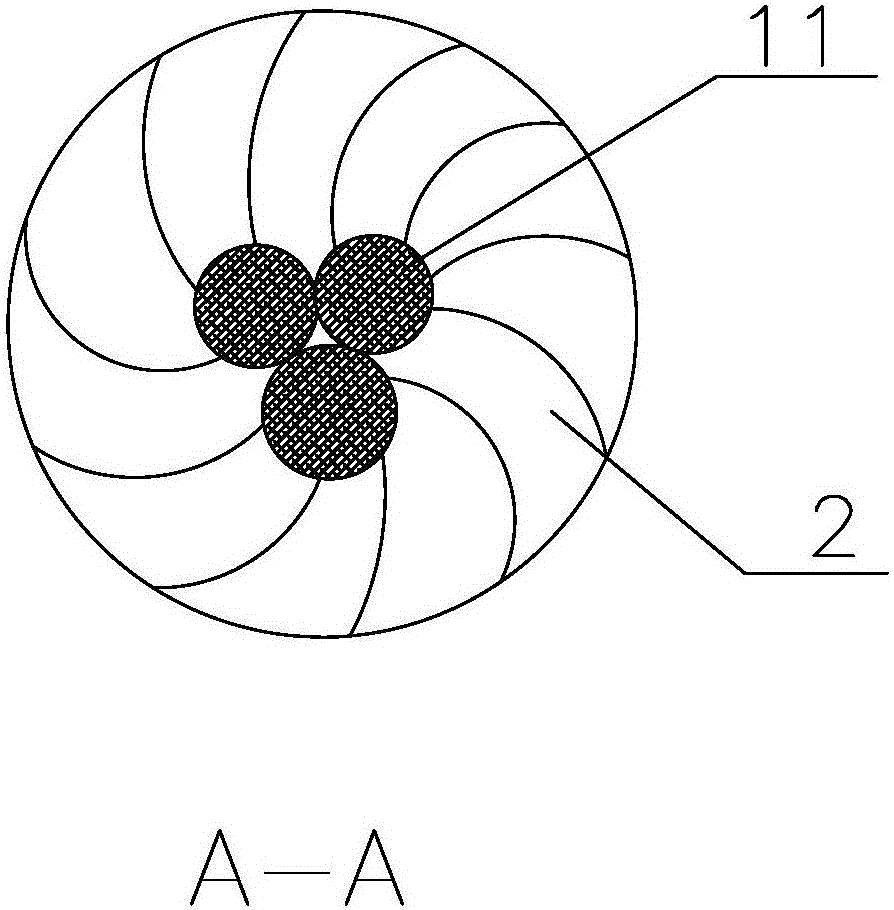

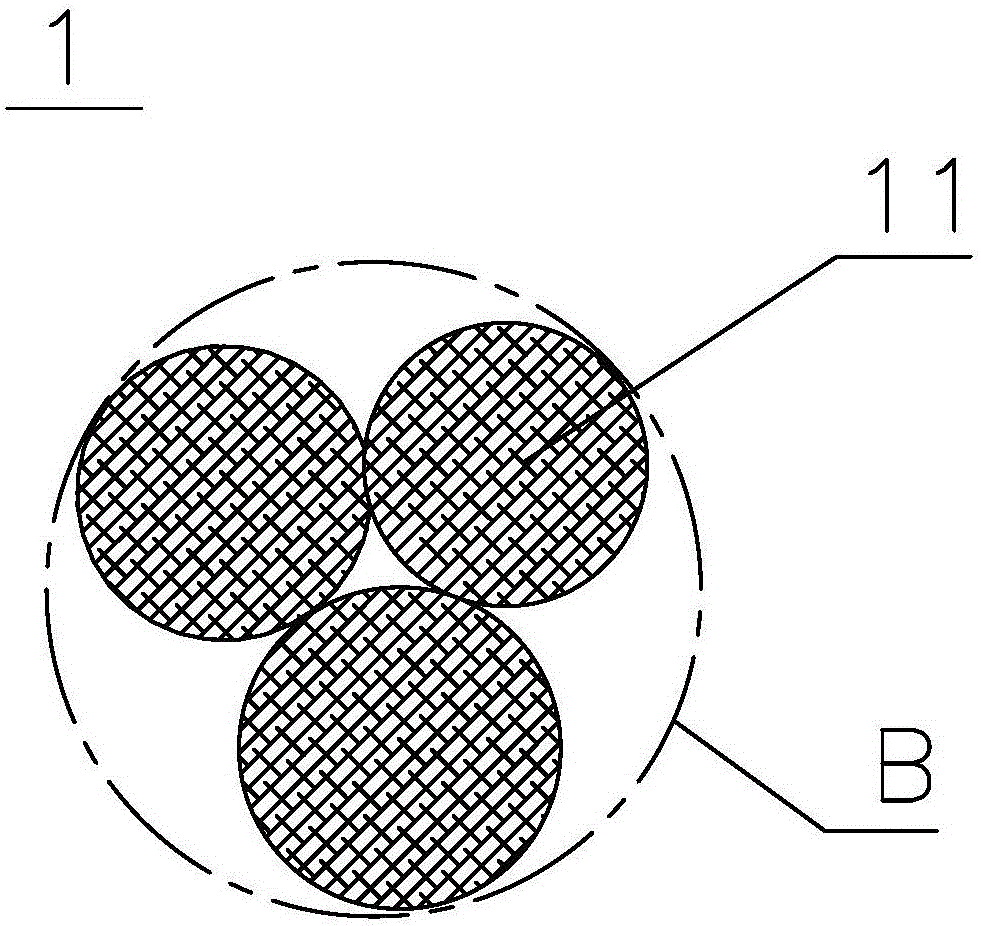

[0030] A multi-core core-spun yarn, comprising a core layer 1 and an outer cladding layer 2, the cross-sectional outer contour of the core layer 1 is roughly circular, the outer diameter of the cross-sectional outer contour of the core layer 1 is 9 μm, and the core layer 1 includes two core yarns 11 The core yarn 11 is a hard core yarn whose breaking elongation is less than 50% as measured by the ISO2062 method, and the outer covering fiber of the outer covering layer 2 is wound and wrapped outside the core layer 1 by a ring spinning core wrapping process. The core yarn 11 has a diameter of 4.5 μm.

[0031] The core yarn 11 is made of glass filaments.

[0032] The outer covering yarn 2 adopts one or more mixtures containing man-made fibers, synthetic fibers or natural fibers.

[0033] A two-for-one twisted yarn, the two-for-one-twisted yarn is formed by two-for-one twisting of four single yarns, and two of the single yarns use the multi-core core-spun yarn described in the se...

Embodiment 3

[0038] A multi-core core-spun yarn, comprising a core layer 1 and an outer cladding layer 2, the cross-sectional outer contour of the core layer 1 is roughly circular, the outer diameter of the cross-sectional outer contour of the core layer 1 is 750 μm, and the core layer 1 includes two core yarns 11 The core yarn 11 is a hard core yarn whose elongation at break is less than 50% as measured by the ISO2062 method, and the outer covering fiber of the outer covering layer 2 is wound and wrapped outside the core layer 1 by a ring spinning core wrapping process. The core yarn 11 has a diameter of 375 μm.

[0039] The core yarn 11 is all made of basalt filaments.

[0040] The outer covering yarn 2 adopts one or more mixtures containing man-made fibers, synthetic fibers or natural fibers.

[0041] A two-for-one twisted yarn, the two-for-one-twisted yarn is formed by two-for-one twisting of three single yarns, and two of the single yarns use the multi-core core-spun yarn described i...

Embodiment 4

[0046] A multi-core core-spun yarn, comprising a core layer 1 and an outer cladding layer 2, the cross-sectional outer contour of the core layer 1 is roughly circular, the outer diameter of the cross-sectional outer contour of the core layer 1 is 24 μm, and the core layer 1 includes two core yarns 11 The core yarn 11 is a hard core yarn whose elongation at break is less than 50% as measured by the ISO2062 method, and the outer covering fiber of the outer covering layer 2 is wound and wrapped outside the core layer 1 by a ring spinning core wrapping process. The core yarn 11 has a diameter of 10 μm.

[0047] Core yarn 11 all adopts metal filament.

[0048] The outer covering yarn 2 adopts one or more mixtures containing artificial fibers, synthetic fibers or natural fibers.

[0049] A two-for-one twisted yarn, the two-for-one-twisted yarn is formed by two-for-one twisting of five single yarns, and three of the single yarns use the multi-core core-spun yarn described in Embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com