Vibration damping structure, vibration damping pad and using method thereof

A technology of vibration-damping structure and vibration-damping pad, which is applied in the field of vibration-damping, can solve problems such as unsatisfactory application, increased vertical dynamic displacement of rails, large damage to rails and fastener springs, etc., so as to reduce train operation safety and Hidden dangers of stability, high comprehensive damping performance, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

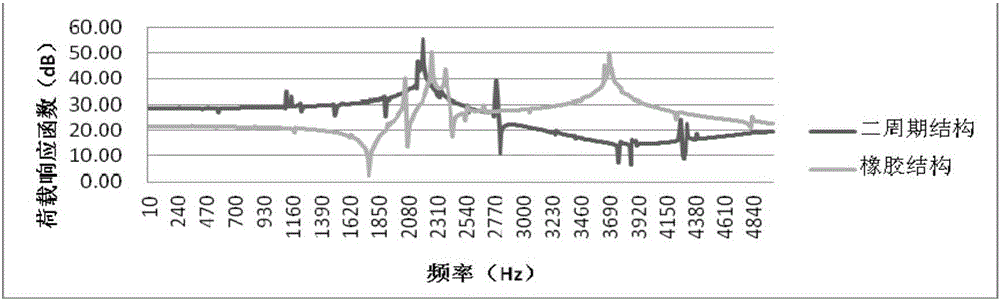

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

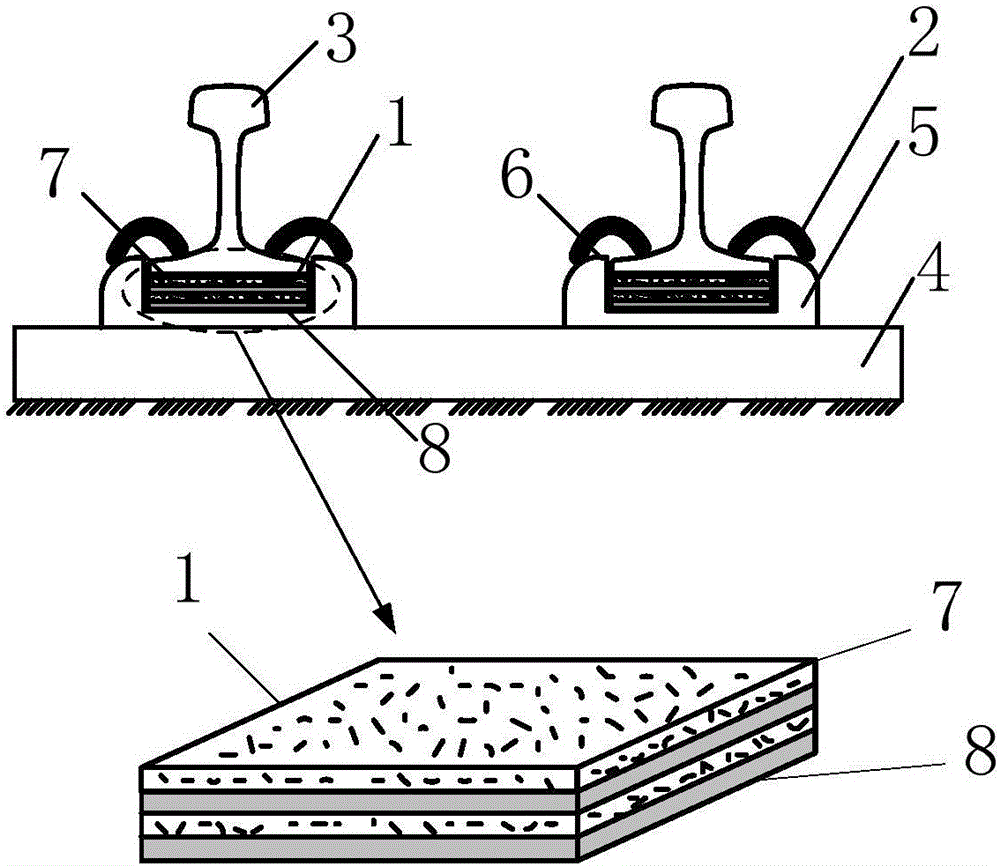

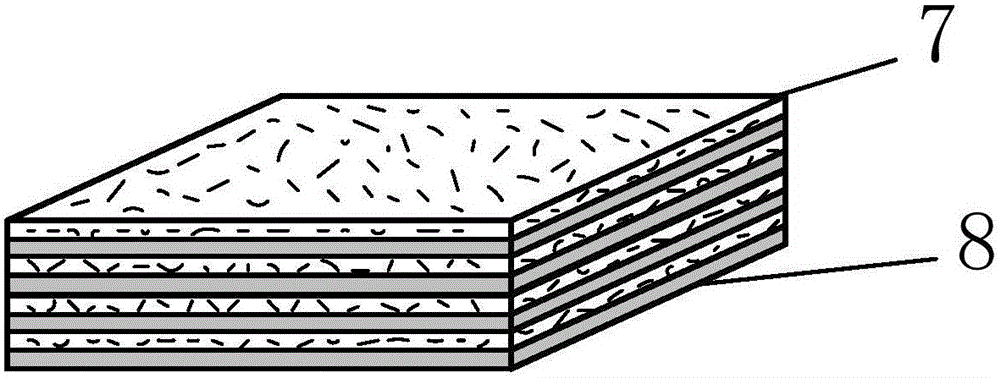

[0029] Embodiment 1: The rail damping pad 1 is composed of several layered periodic units in the thickness direction, and the layered periodic units are formed by overlapping several layers of periodic substructures, and the composition materials of adjacent periodic substructures are different; The constituent materials of the periodic substructure are divided into elastic material 7 and rigid material 8 , preferably, the elastic material 7 can be rubber material or resin material, and the rigid material can be alloy material or metal material 8 . Such as figure 1 shown.

[0030] The thickness dimension of the periodic substructure of each layer in the periodic unit of the rail damping pad 1 is consistent with the vibration wavelength of interest to improve the vibration damping effect, and its width and length match the size of the rail bearing part of the iron backing plate under the rail.

[0031] The shape of the periodic substructure of the rail damping pad 1 is a cuboi...

Embodiment 2

[0034] Embodiment 2: The periodic substructure of the rail vibration damping pad 1 can also be provided with several periodic substructures in the length and width directions. These periodic substructures include holes 9 and fillers 10. The holes must be It is the same structural size, the same regular distribution, and equal intervals in all directions; several columns or cones and filling bodies 10 of other shapes can be arranged in these holes 9, and then laminated with the periodic track plate 1 to form a whole. The longitudinal length and the horizontal width are arranged at regular intervals, such as Figure 5 shown. Preferably, in addition to the form of the columnar periodic slave structure 9, a conical periodic slave structure can also be used, which has a good vibration damping effect and low construction difficulty.

[0035] The period of the rail damping pad 1 should be greater than 3 from the number of holes 9 in the structure and the number of structures in the ...

Embodiment 3

[0037]Embodiment 3: The application of the present invention is not limited to rail transit, and can be put into use in fields requiring vibration reduction measures such as mechanical equipment and buildings after slightly adjusting the structural size. For example, a layer of vibration damping pads with layered periodic structure characteristics can be added to the floor of a residential building to weaken the vibration of the floor and greatly reduce the noise impact of the living activities of the upstairs residents on the downstairs residents. ;The vibration of the hull caused by the operation of the marine machine will not only affect the crew's sense of body, cause ocean noise, but also weaken the strength of the hull. A layer of vibration damping pad with layered periodic structure characteristics is added between the installation plate of the machine and the hull base plate , can effectively weaken the damage caused by the vibration of marine machinery; and the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com