Initial heat supply network station for waste heat utilization of coal-fired power plant

A technology for coal-fired power plants and heating networks, which is applied in applications, household heating, heating methods, etc., and can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention is described in detail below in conjunction with specific examples. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

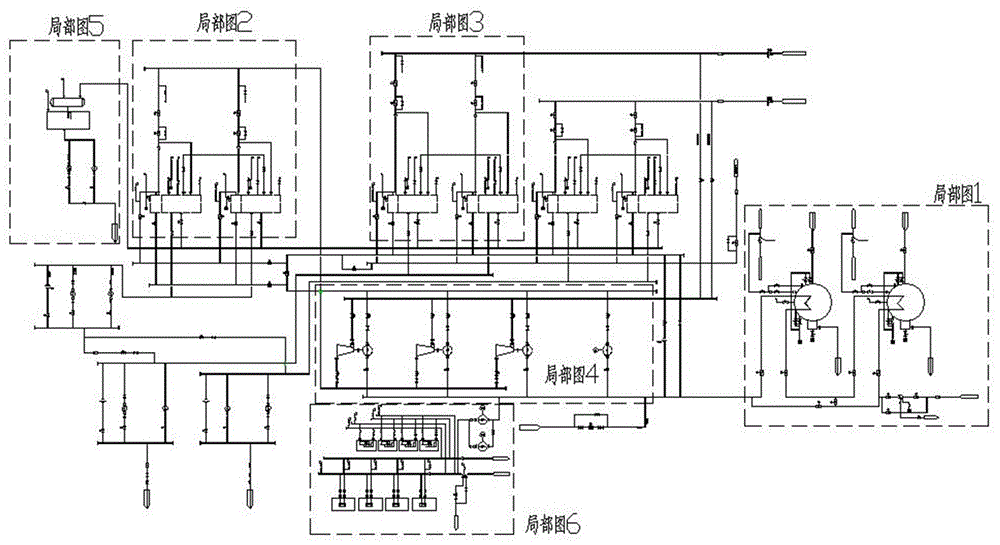

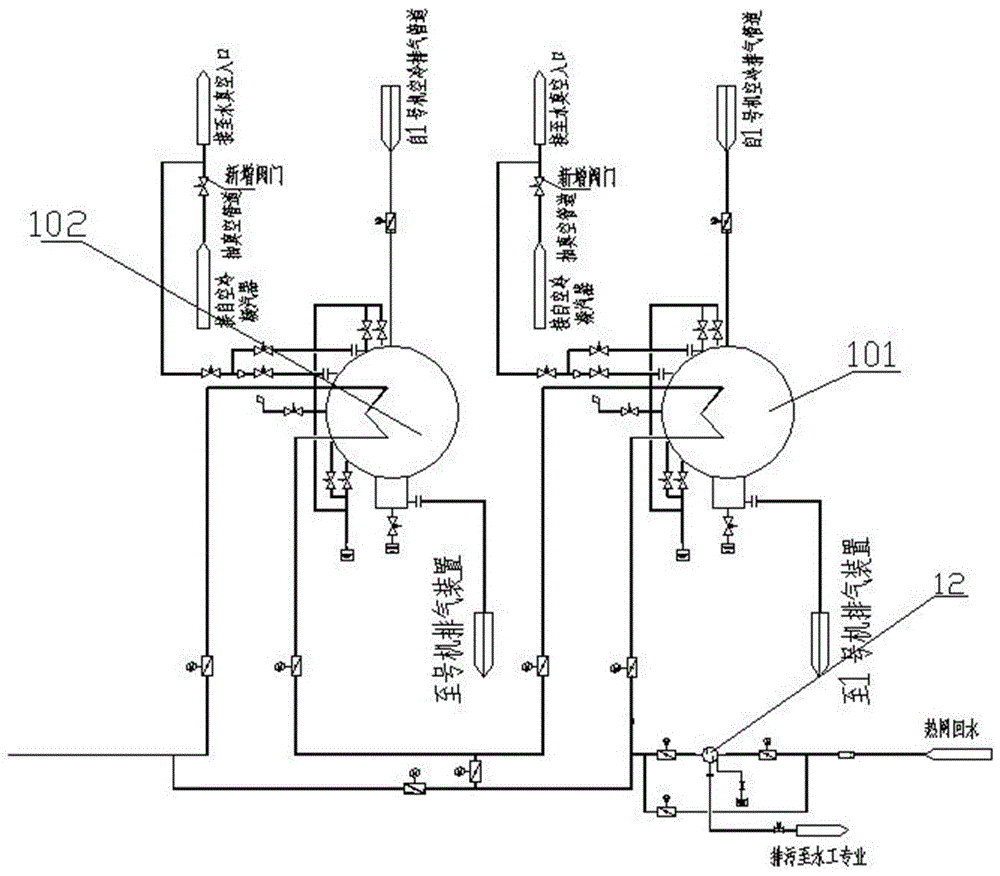

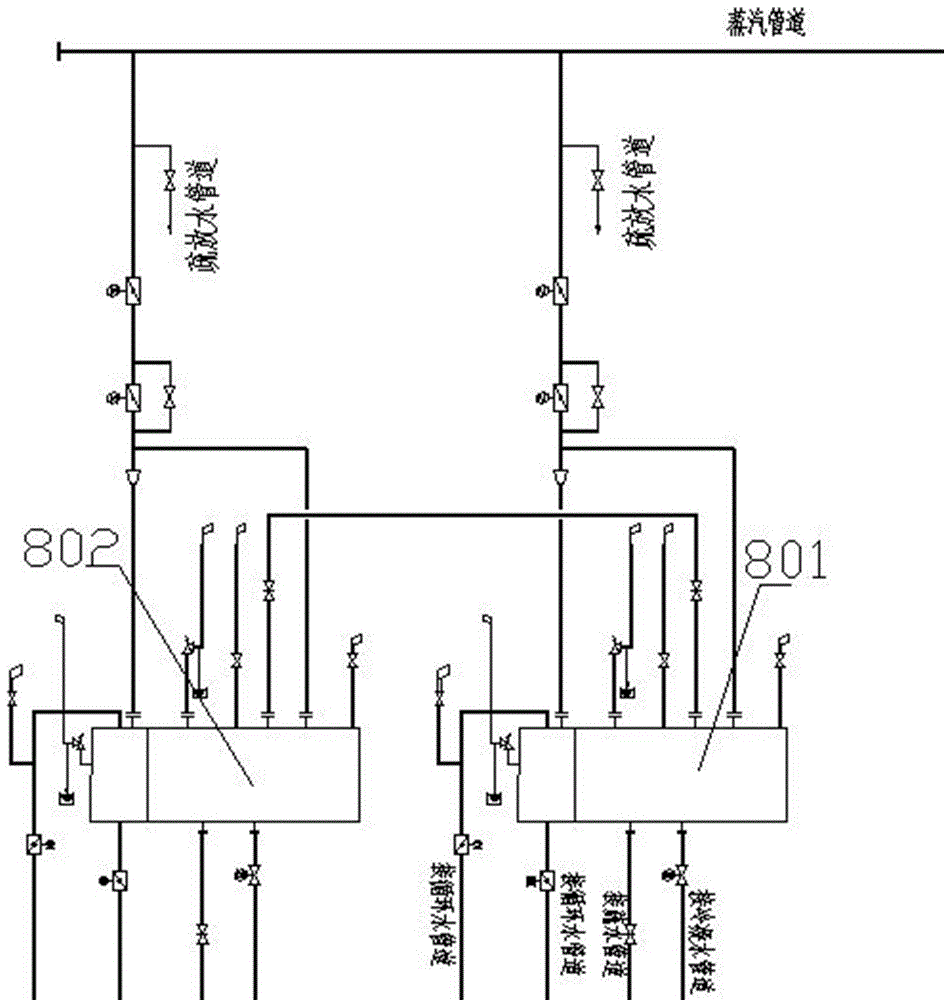

[0016] As shown in the figure, a coal-fired power plant waste heat utilization heat network first station includes a condenser (1) and a heat network. The condenser (1) uses high back pressure steam turbine exhaust steam to heat circulating water. The heat The plant is mainly composed of a heat network circulating water pump, an exhaust cooler (8) and a heat network heater (2). The exhaust cooler (8), heat network heater (2) and the condenser (1) are connected in series The heating network circulating water pump has three back pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com