A method of measuring and visualizing mine shaft material level based on a small unmanned aerial vehicle

A technology of small unmanned aerial vehicle and chute material level, which is applied in the direction of measuring device, engine lubrication, liquid/fluid solid measurement, etc. It can solve the problems of potential safety hazards, poor inspection effect, complicated detection process, etc., and achieve a wide range of applications , wide application range, fast scanning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

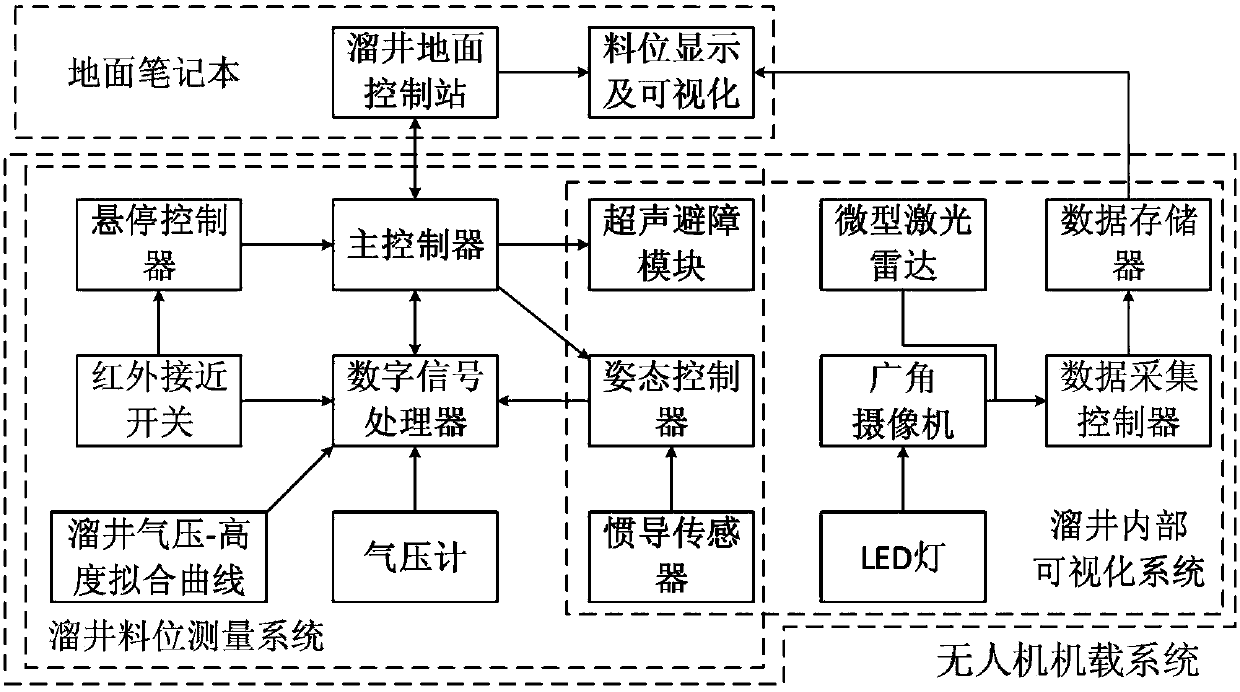

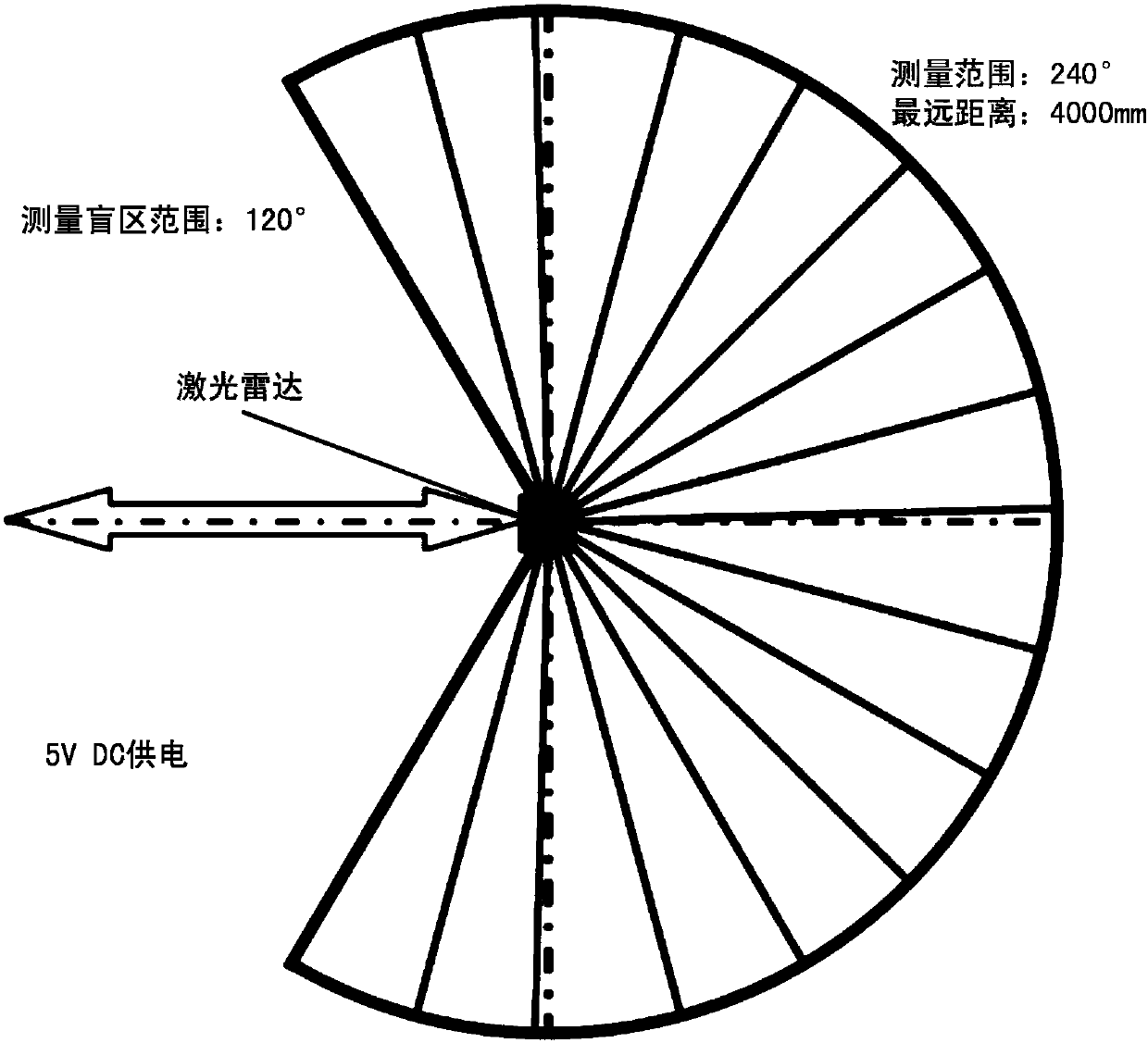

[0022] The stated purpose of the present invention is realized by the small-sized four-rotor unmanned aerial vehicle platform carrying two-dimensional laser radar proposed below. In addition to flight parts, flight control system and battery, the UAV platform also includes ultrasonic obstacle avoidance system, barometer with temperature compensation function, infrared proximity switch, miniature laser radar, miniature wide-angle camera, 256GB high-speed flash memory card, digital signal processor. The technical scheme adopted in the present invention is that the UAV approaches the material level downward along the chute, and the infrared proximity switch directly below it can hover at a certain distance after sensing the material level. The signal processor obtains the depth information of the chute; a small lidar and a miniature wide-angle camera installed on the UAV can provide a complete scan and visualization of the chute wall.

[0023] Technical scheme of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com