Power machinery closed loop face-to-face double gear case inclination type excitation test stand

A technology of power machinery and gearbox, which is applied in the field of power machinery closed-loop face-to-face dual-gearbox side-tilting excitation test bench, can solve problems such as energy waste, reduce the number of tests, save energy, and ensure correctness and authenticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

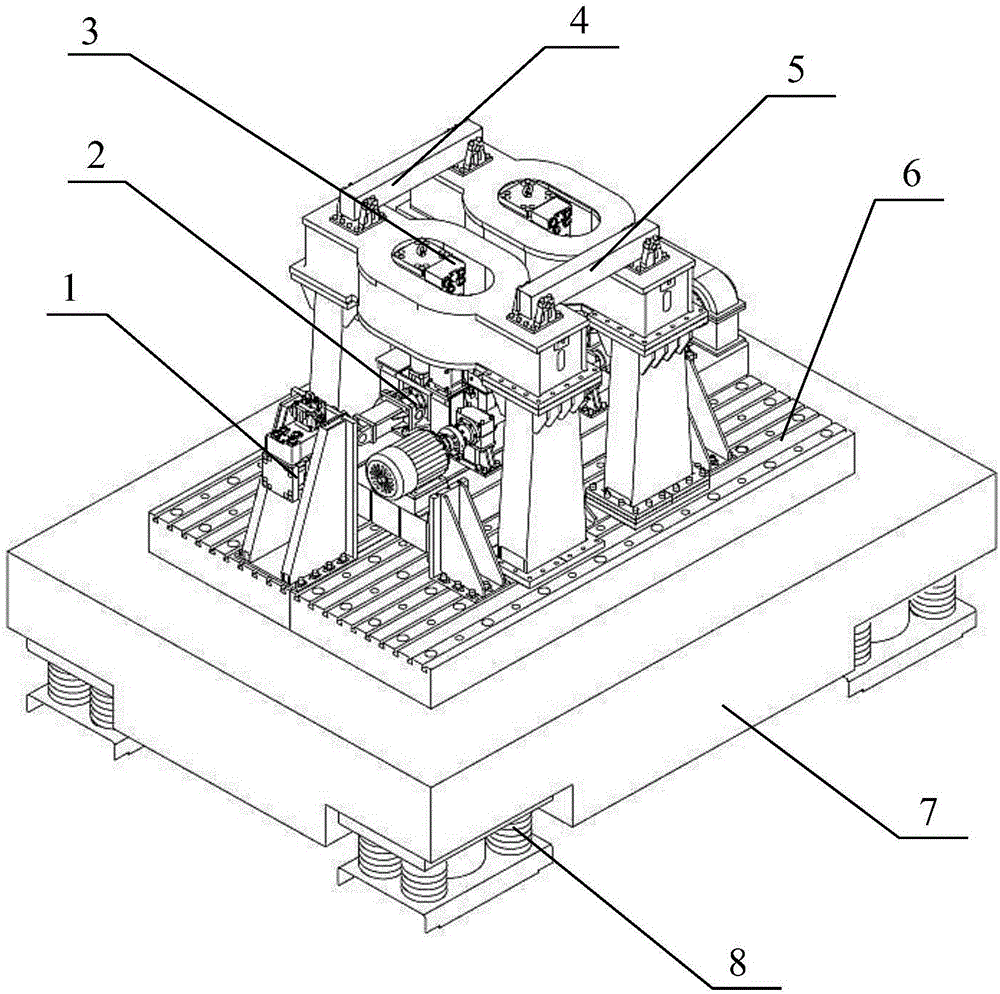

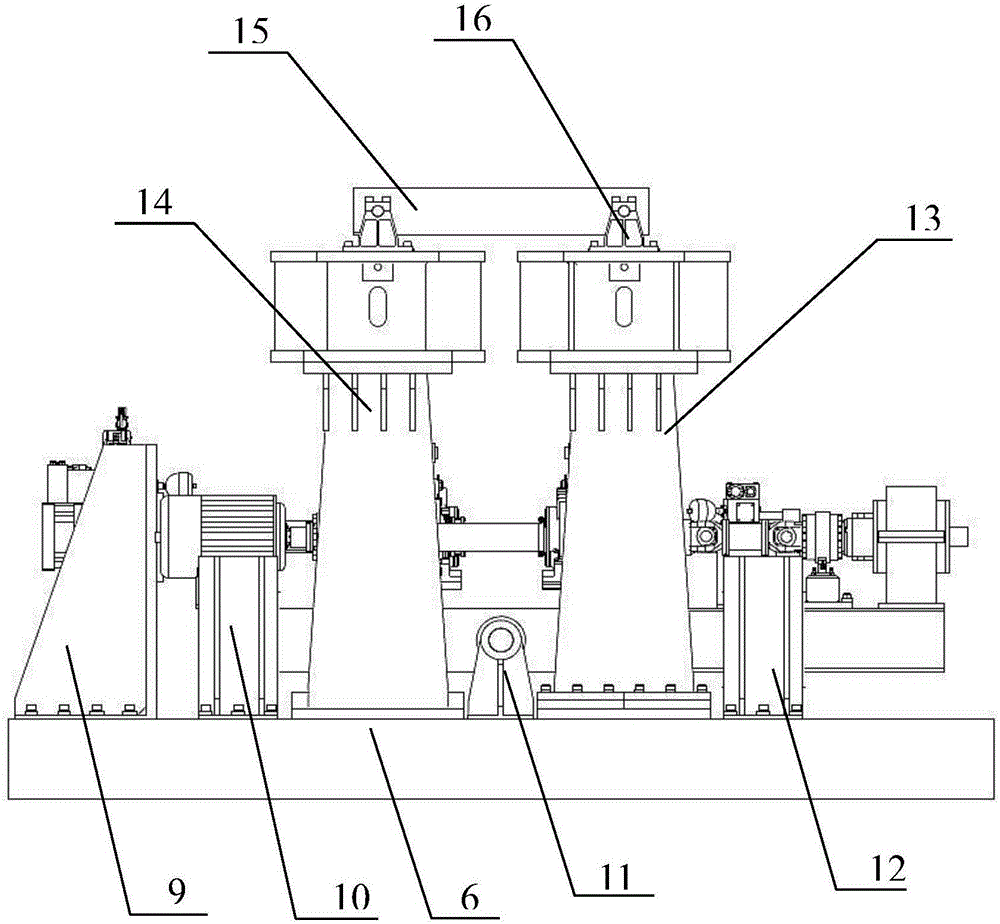

[0057] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0058] The purpose of the present invention is to provide a power machinery closed-loop face-to-face dual gear box side-tilting vibration test bench, which solves the problem that it is difficult to carry out gearbox reliability tests in the actual operation of existing rail vehicles, so as to meet the needs of rail vehicles in various operating conditions. The need for reliability parameter testing under certain conditions.

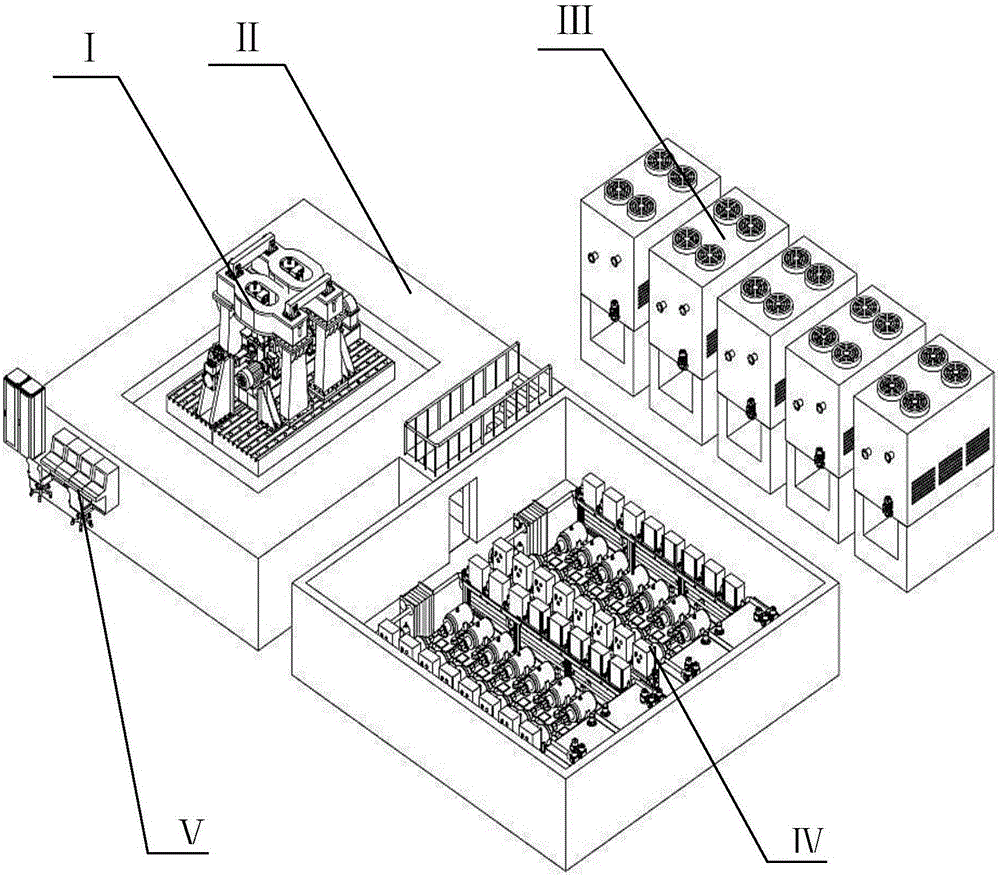

[0059] like figure 1 As shown in the present invention, the power machinery closed-loop face-to-face dual gear box side-tilting vibration test bench I, the test bench foundation II, the oil source cooling system for the vibration actuator III, the oil source system IV for the vibration actuator and the measurement and control system Ⅴ used together.

[0060] The test bench foundation II is used to provide an installation foundation for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com