A flexible tooling structure with variable stringer position

A technology of flexible tooling and stringers, applied in the field of experimental tooling design of main load-bearing components of aerospace structures, can solve problems such as structural asymmetry, structural deformation no longer satisfying the assumption of flat section, and experimental load distribution requirements, etc., to achieve Improve the force transmission path and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] The invention adopts aluminum alloy material to manufacture a flexible tooling structure with variable stringer positions, so as to realize the purpose of accurate simulation of experimental load distribution.

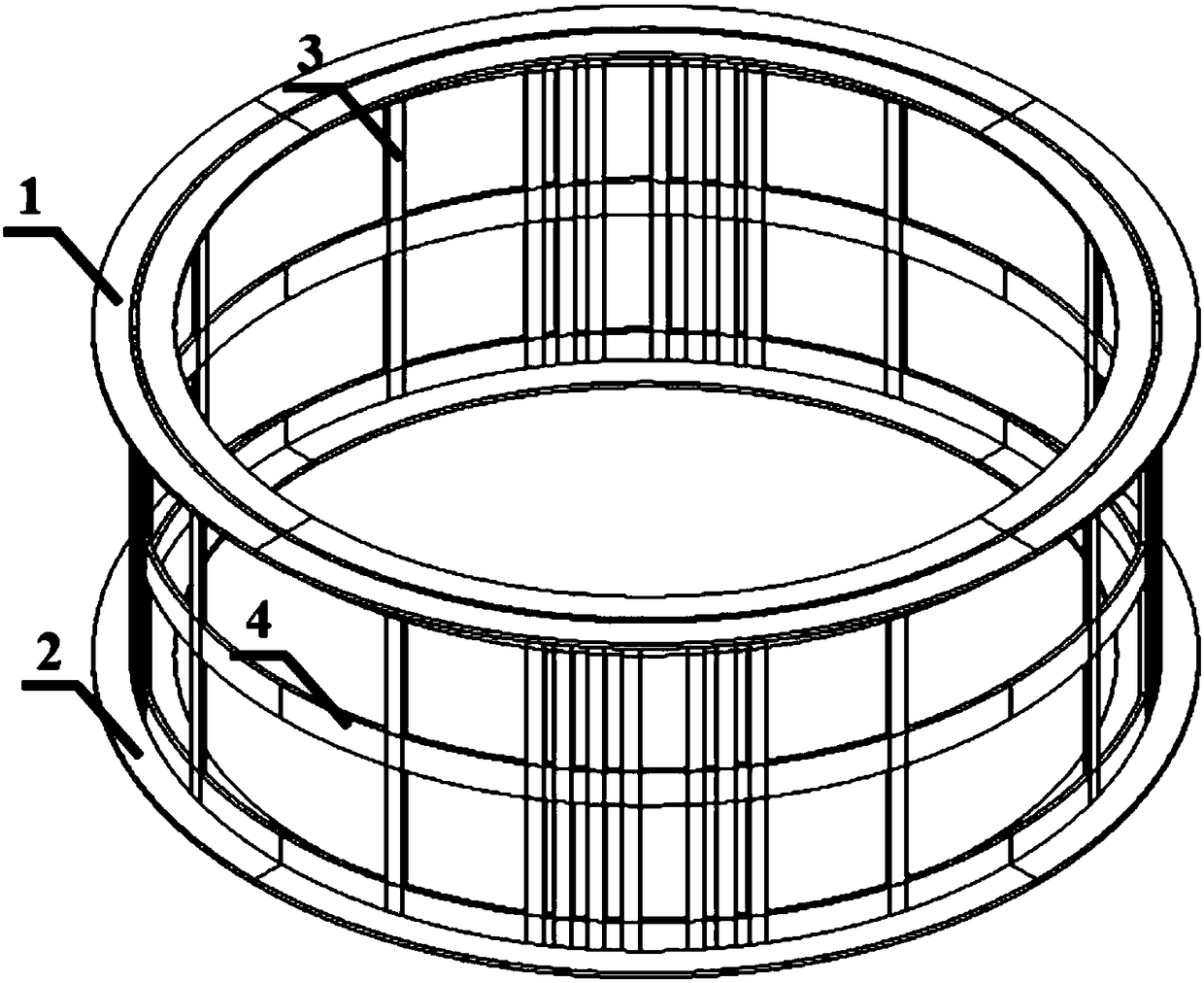

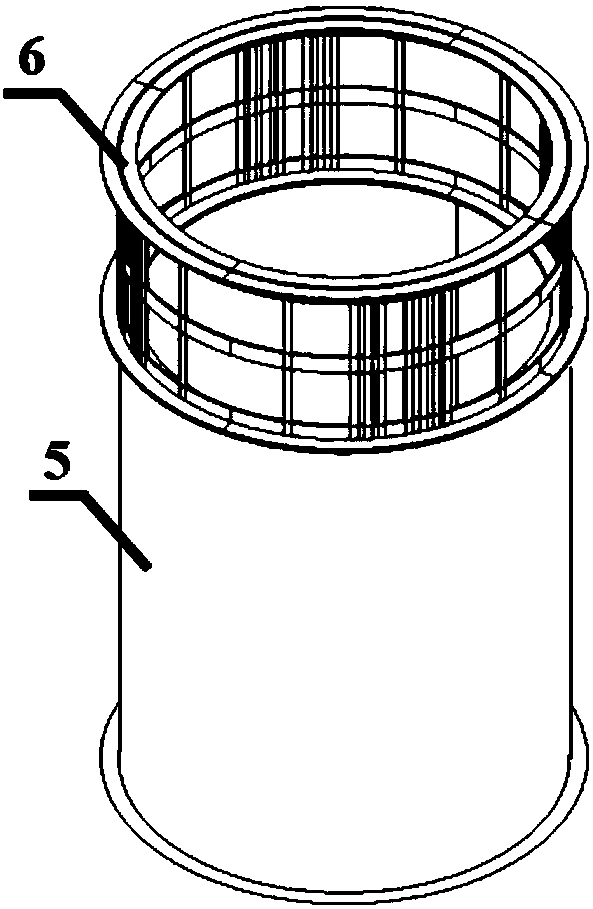

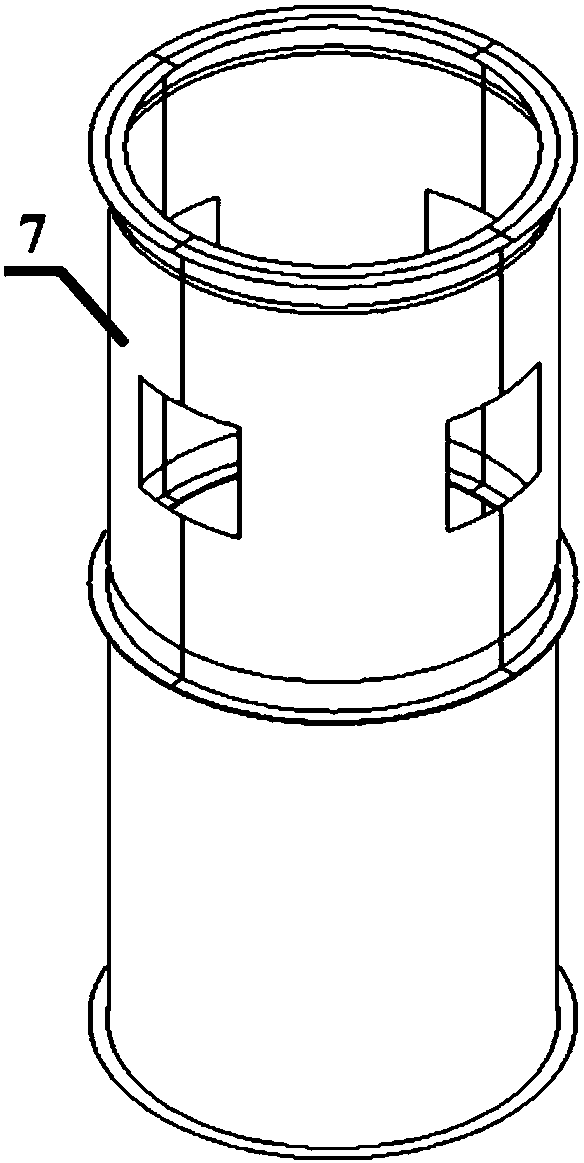

[0017] refer to figure 1 According to the present invention, the flexible tooling structure with variable stringer positions includes the upper end frame 1 of the flexible tooling, the lower end frame 2 of the flexible tooling, the transverse stringers 3 of the flexible tooling and the longitudinal stringers 4 of the flexible tooling. The flexible structure can be manufactured by welding process. The horizontal stringers and vertical stringers are distributed alternately, forming a grid pattern. The upper end of the transverse stringer extends out of the upper end frame, and the lower end of the transverse stringer extends out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com