Fire monitoring method and system for containment vessel of nuclear power station during bulge test

A nuclear power plant containment and pressure test technology, applied in nuclear power generation, fire alarms, nuclear reactor monitoring and other directions, can solve the problems of single judgment scheme, lack of redundancy, poor timeliness of monitoring means, etc., to improve timeliness and accuracy, The effect of reducing unpredictable losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

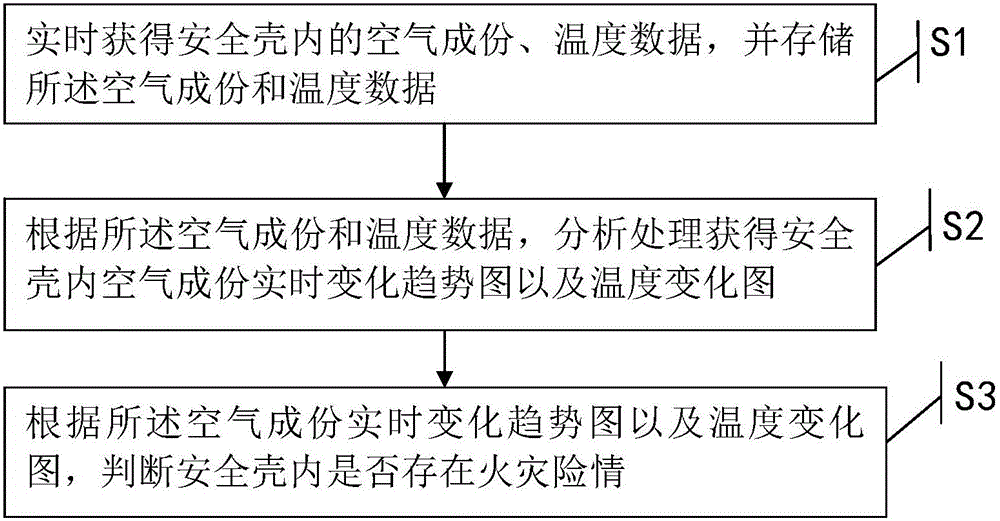

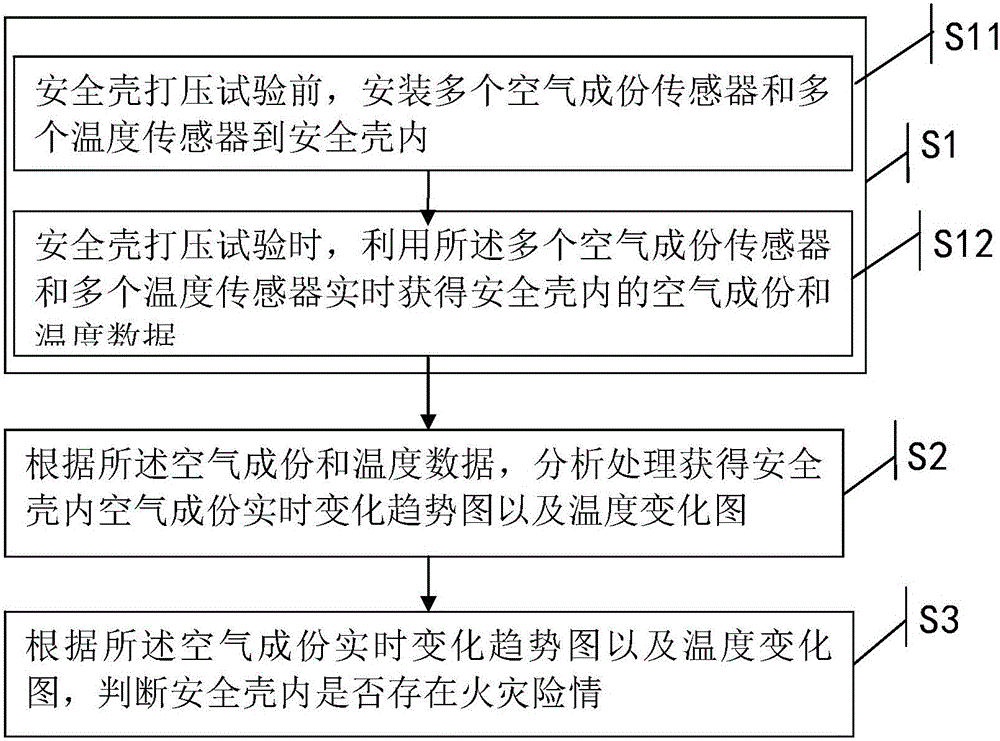

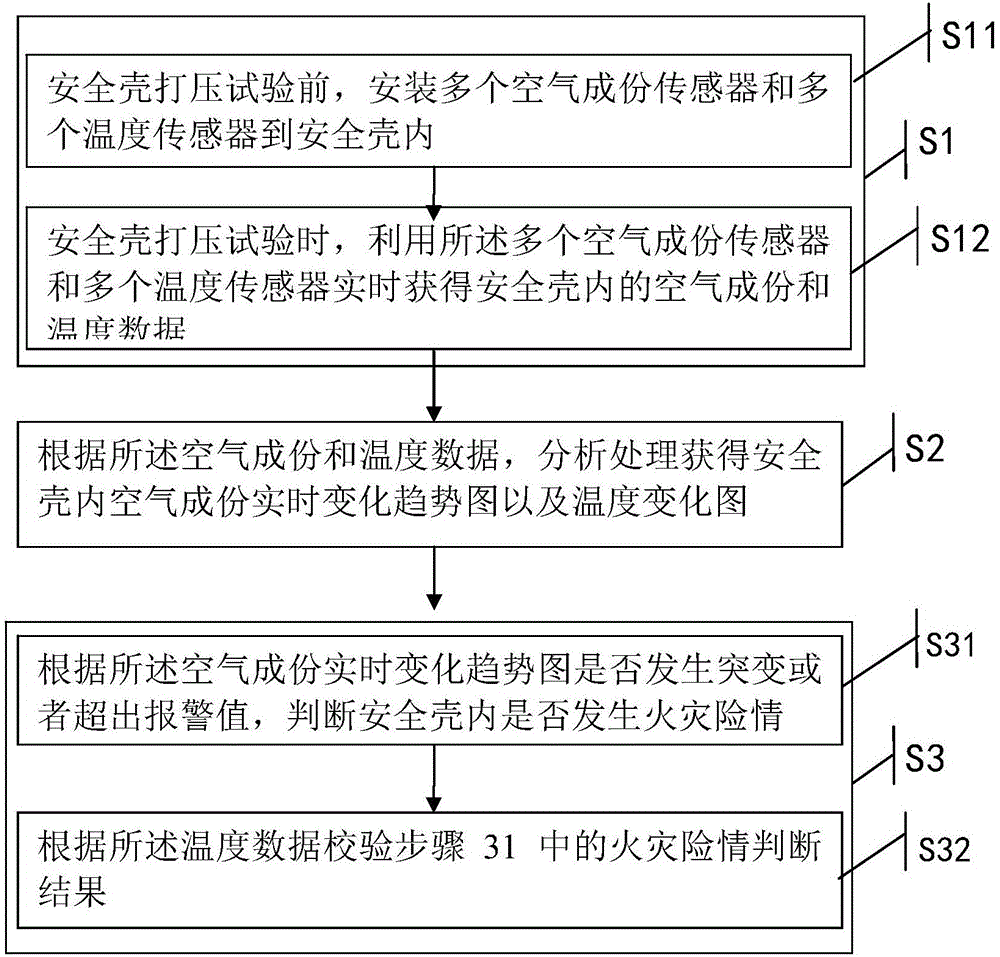

[0044] In the embodiment of the present invention, by providing a fire monitoring method during the containment pressure test of a nuclear power plant,

[0045] It solves the technical problems of poor timeliness, lack of redundancy, single judgment scheme and large error in the existing fire monitoring means during the containment suppression test of the nuclear power plant.

[0046] The technical solution of the embodiment of the present invention is to solve the above-mentioned technical problems, and the general idea is as follows:

[0047]Since the island is in a high-voltage state during the containment pressure test, this system uses smoke sensors and gas-sensitive resistance sensors as the main monitoring equipment, and sends the data on the island to the duty room through electrical penetrations. The gas sensitive resistor and the smoke sensor send the real-time collected signal to the monitor of the host computer in the duty room through the electrical penetration, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com