A coal preparation and desliming system

A technology of desliming and coal preparation, which is applied in the field of coal mines, can solve problems such as electricity waste, and achieve the effects of reducing costs, reducing investment, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions and effects of the present invention will be further described below through specific embodiments. The following embodiments are only used to illustrate the content of the present invention, and are not intended to limit the protection scope of the present invention. Simple changes made to the present invention by applying the concept of the present invention are all within the scope of protection of the present invention.

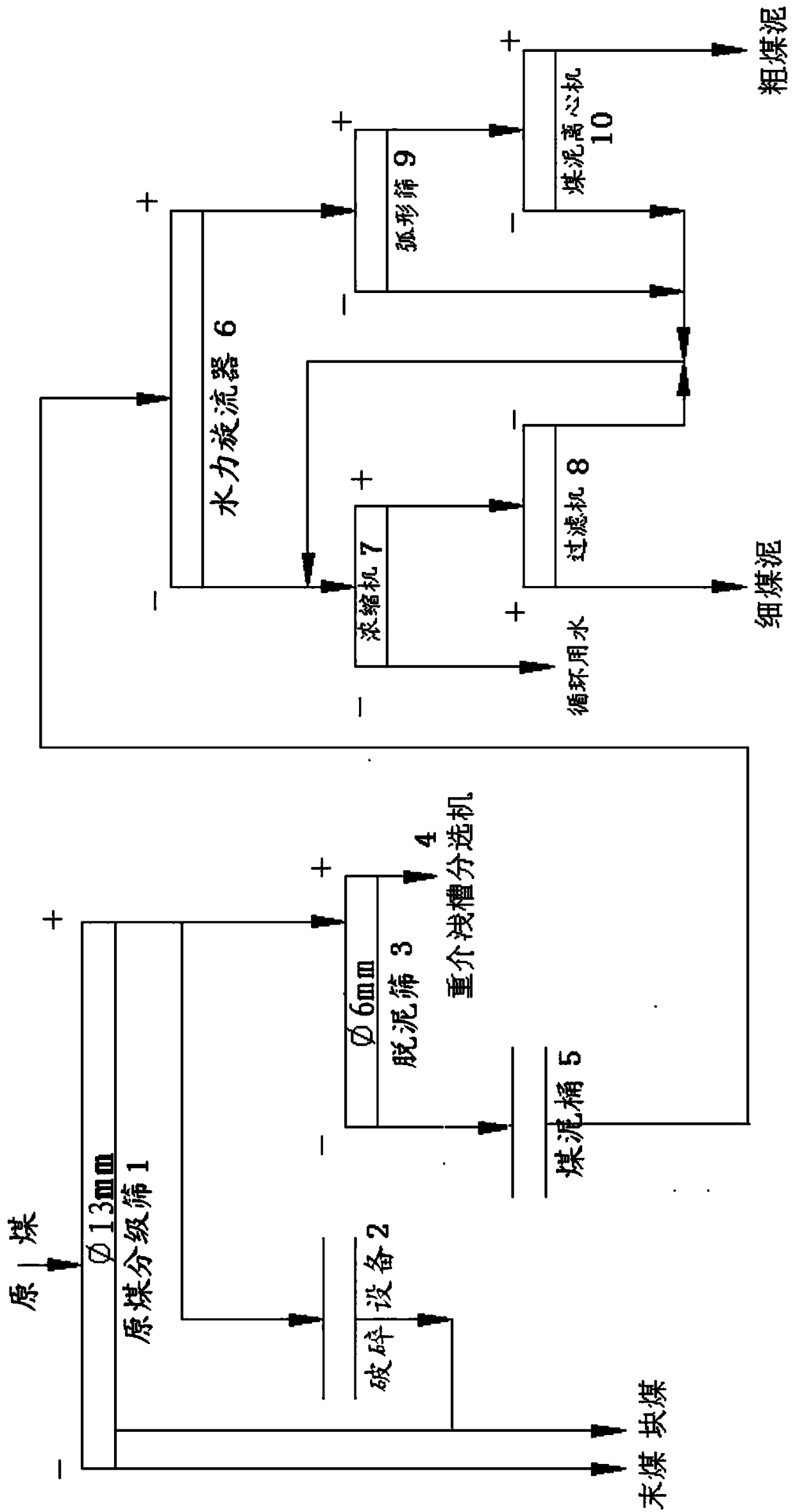

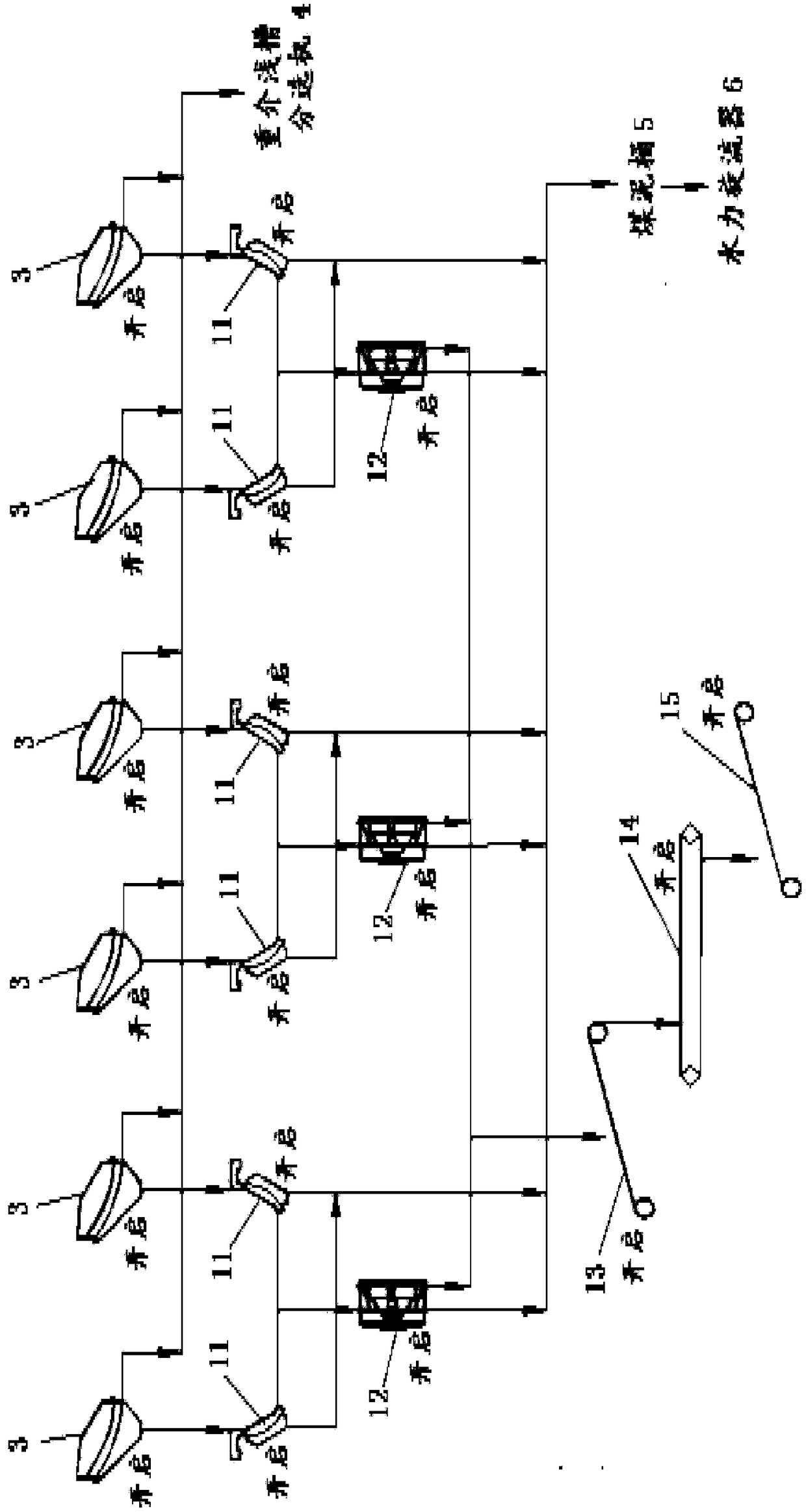

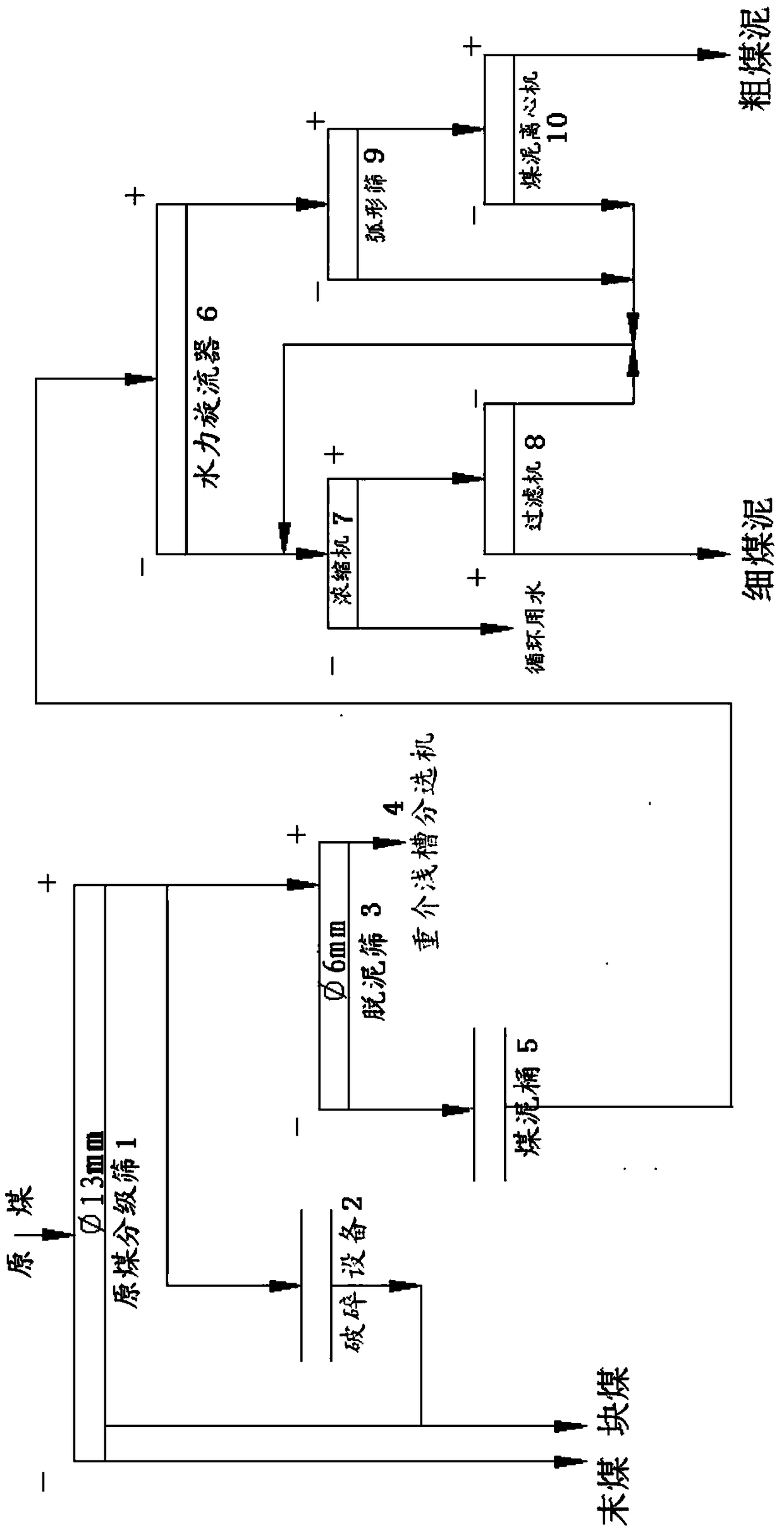

[0050] Coal preparation desliming system of the present invention, as Figure 3-5 shown, including:

[0051] Raw coal grading screen 1: used for 13mm grading of raw coal;

[0052] Desliming screen 3: used for desliming and screening the material larger than 13 mm from the raw coal grading screen 1, and the sieve plate of the desliming screen 3 is a 3 mm sieve plate;

[0053] Dense Medium Shallow Tank Separator 4: Used to receive the material on the screen from the desliming screen 3 to obtain shallow tank clean coal, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com