3D printer sprayer with rotation switching function

A technology of 3D printers and nozzles, applied in the direction of additive processing, etc., can solve problems such as the trouble of replacing nozzles of extruders, low printing efficiency of 3D printers, etc., and achieve the effects of reducing deformation, improving printing accuracy, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

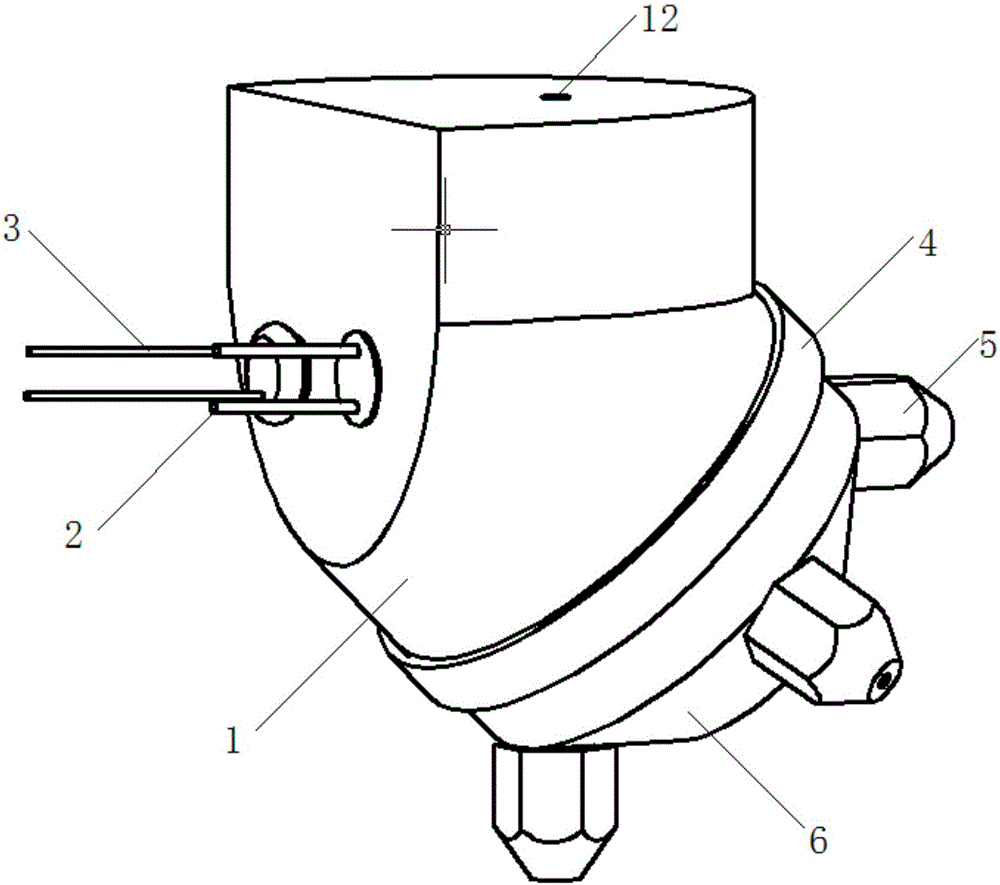

[0026] A rotatable and switchable 3D printer nozzle according to the present invention includes a fixed seat 1, a heating rod 2, a thermocouple 3, a retaining ring 4, a nozzle and a rotating seat 6; the nozzles include No. 1 nozzle 5 and No. 2 nozzle , No. 3 nozzle and No. 4 nozzle.

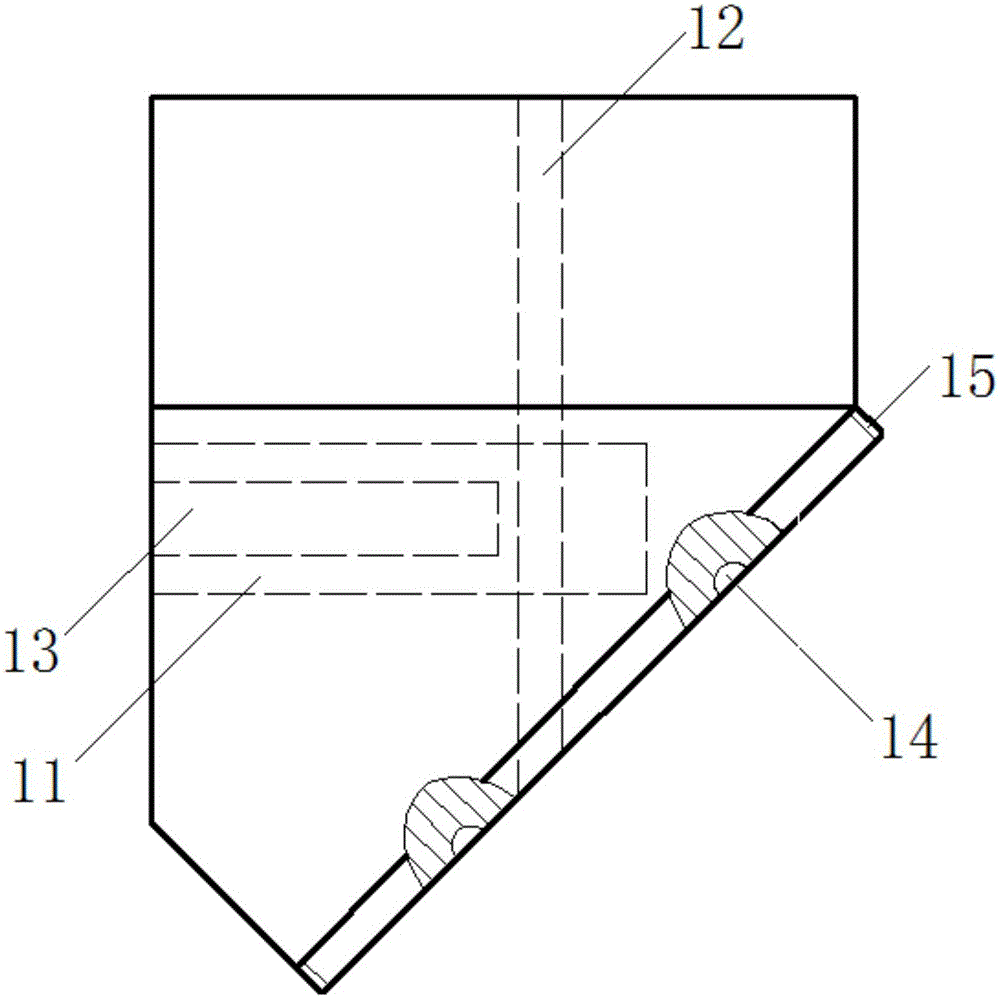

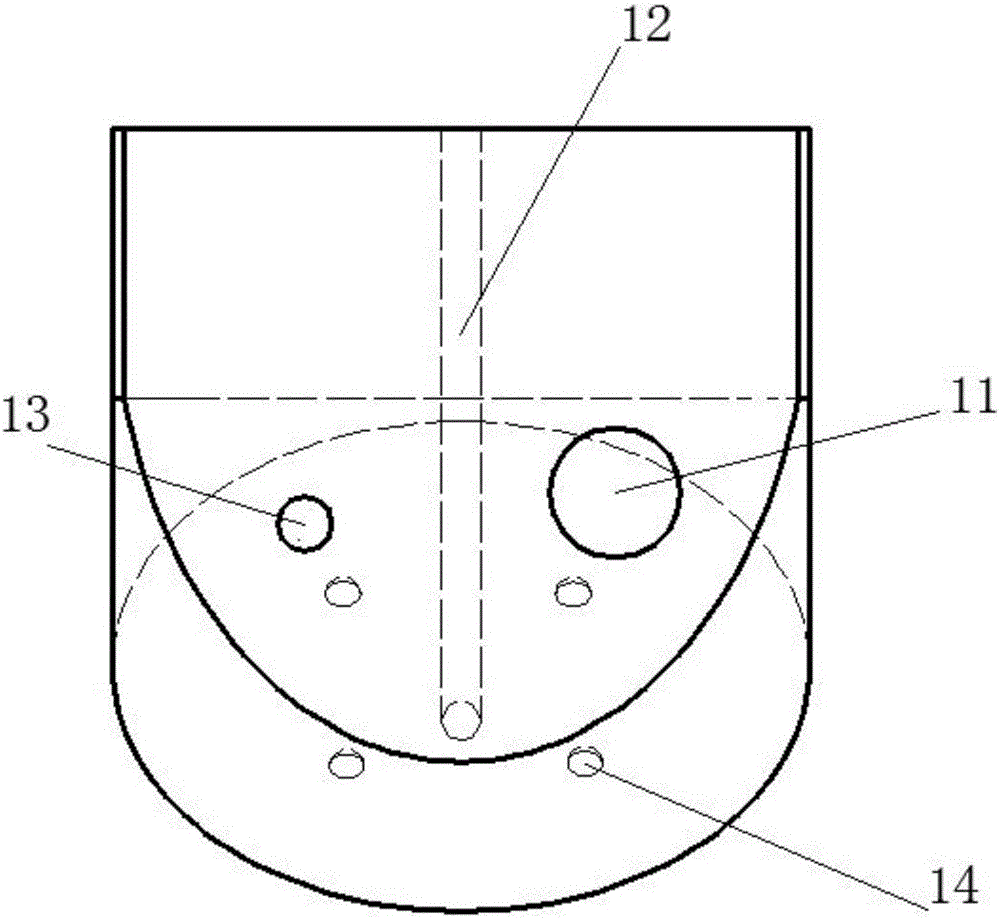

[0027] refer to figure 2 and image 3 , the fixed seat 1 is composed of two equal-diameter upper cylinders intersecting with the lower cylinder, the rotation axes of the upper cylinder and the lower cylinder intersect to form an included angle of 135 degrees, and a vertical Straight side, the vertical side is parallel to the axis of rotation of the upper cylinder, and perpendicular to the plane where the axis of rotation of the upper cylinder and the lower cylinder intersect, and the lower cylinder of the fixed seat 1 is provided with a horizontal heating rod installation hole 13 With the the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com