An automatic glazing assembly line for bathroom products

A bathroom product and assembly line technology, applied in the field of bathroom products, can solve the problems of high labor intensity, inability to spray bathroom products, and low spraying efficiency, and achieve the effect of reducing labor amount, eliminating human defects, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below through specific embodiments.

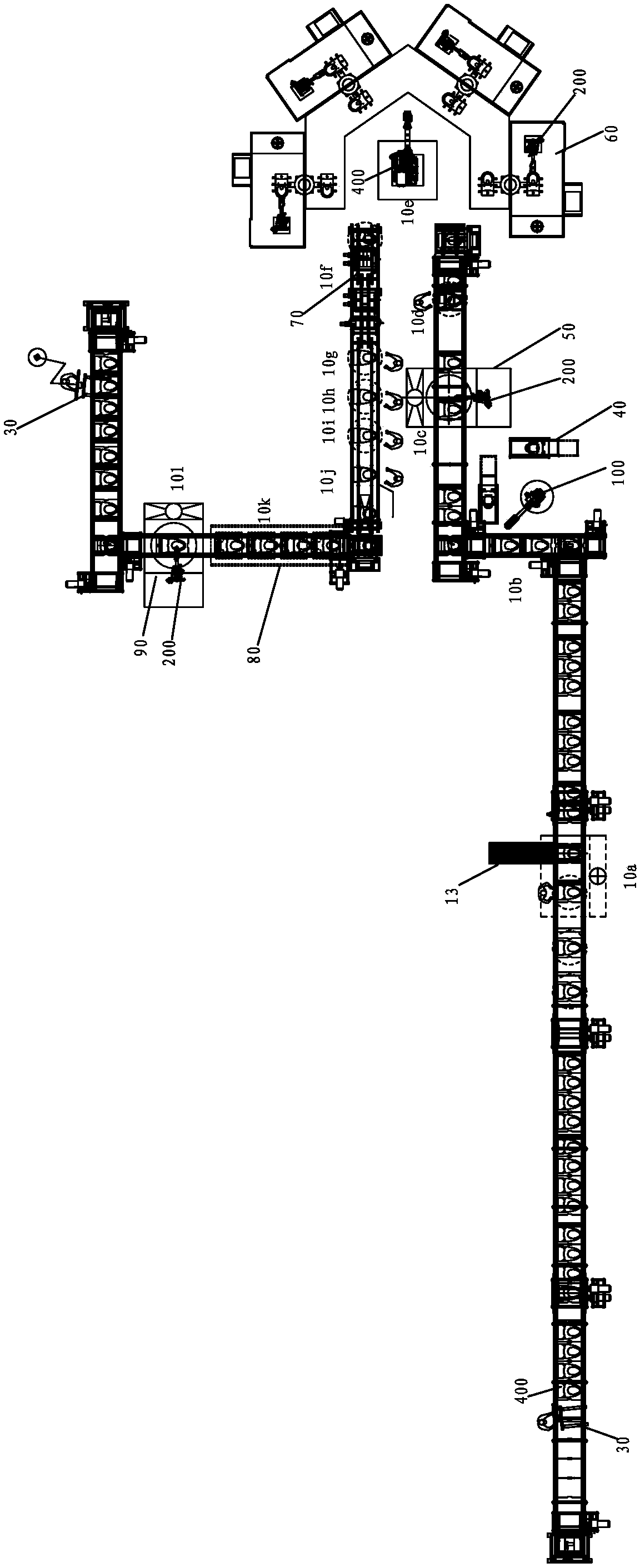

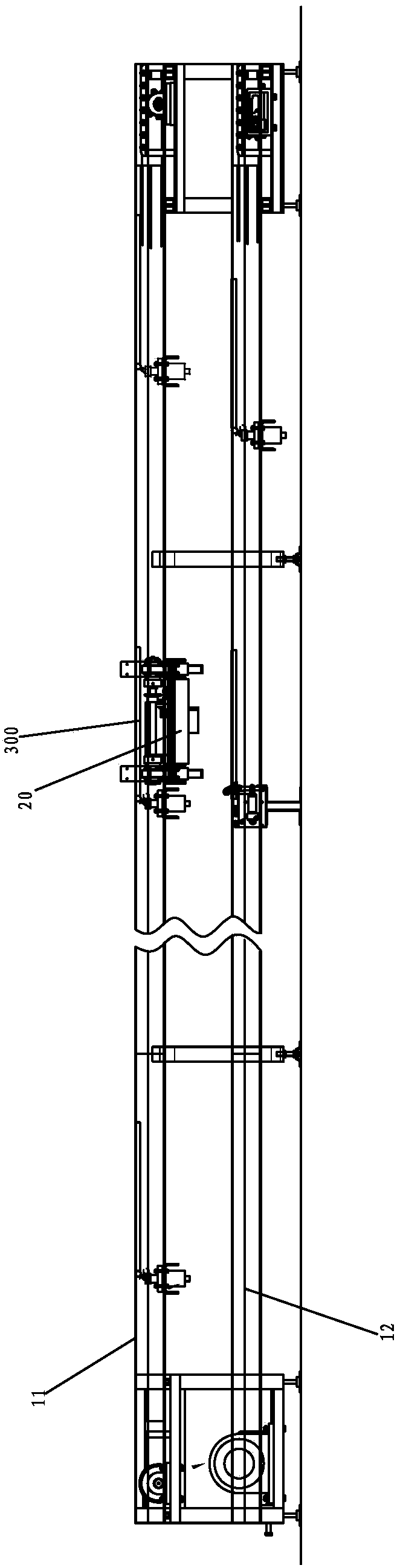

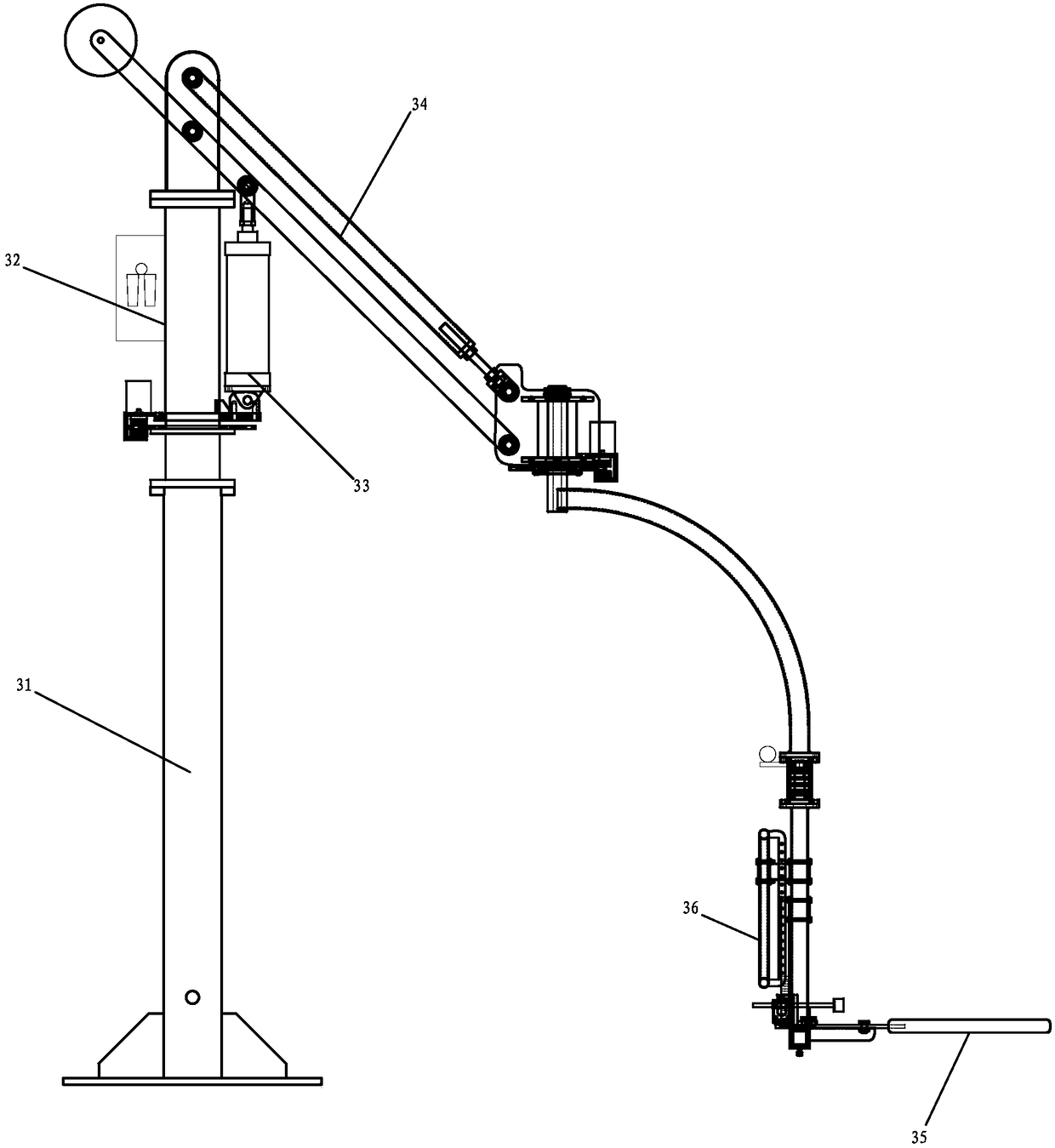

[0046] refer to Figure 1 to Figure 13 , an automatic glazing assembly line for bathroom products, including a product conveying line 10 and a control system connected thereto. 300 and the upper conveyor line 11 of the product 400 and the lower conveyor line 12 of the empty pallet 300. It drives the pallet 300 up or down to switch between the two layers through the automatic board returning device 20, which is connected with the control system. A translation mechanism is also provided at the corner of the product transmission line for guiding the product 400 and turning the pallet 300 to ensure that the product 400 is transplanted to another section of the transmission line smoothly and safely. The translation mechanism can adopt the existing translation machine to realize steering and translation. In addition, a booster device 30 is provided at the starting position of the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com