Improved recycling device for producing 3-amino-1-adamantanol

A technology for adamantanol and amino groups is applied in the field of recovery and improvement devices for the production of 3-amino-1-adamantanol, which can solve problems such as loss of raw materials, incomplete product centrifugation and the like, and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

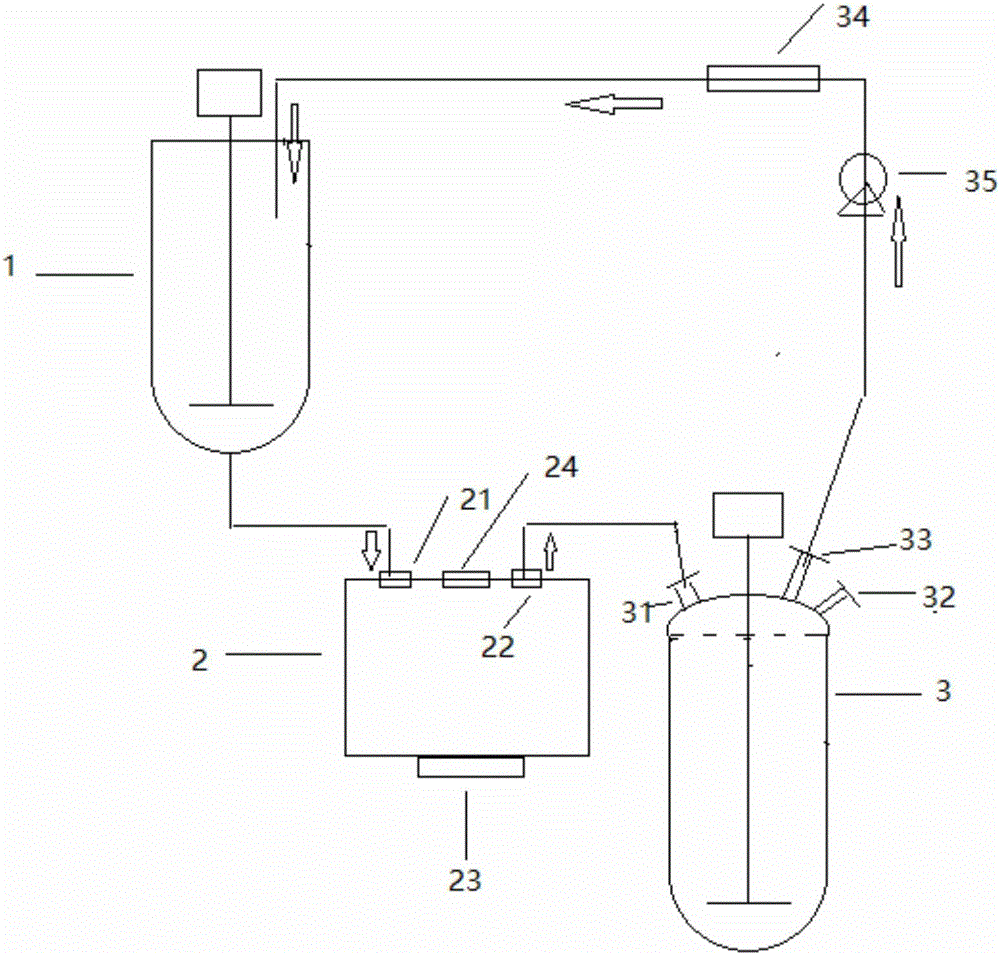

[0020] figure 1 Show a kind of recovery improvement device that produces 3-amino-1-adamantanol, comprise reactor 1, centrifuge and extractor 3; Described centrifuge comprises the centrifuge bucket 2 that slurry is centrifuged; Described The upper end of the centrifuge barrel is provided with a centrifugal feed port 21 for slurry and water to enter, and a centrifugal discharge port 24 for throwing out the discharge liquid when the slurry is centrifuged; the upper end of the centrifugal device is provided with a gas collector 24, and the The gas collector is connected with the tail gas absorption device. The lower end is provided with a centrifugal discharge port 23 for discharging the material generated after the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com