Reflective insulation colorful coating and preparation method thereof

A multi-color paint and color technology, which is applied in the direction of reflection/signal paint, multi-color effect paint, polyurea/polyurethane paint, etc., can solve the problems of affecting product performance, high price, and the decline of reflective heat insulation effect, so as to improve the energy saving effect , heat insulation effect is good, the effect of saving building air conditioning energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Preparation of reflective and heat-insulating colorful coatings

[0063] The present embodiment is made up of the following components, all are weight ratios, protective sol: dispersed phase base paint: continuous phase varnish=30:35:50, wherein,

[0064] The composition of the weight ratio of each component of the dispersed phase base paint:

[0065] Deionized water 21.4%

[0066] Hydroxyethyl Cellulose 0.9%

[0067] PH regulator 0.1%

[0068] Disperse wetting agent 0.3%

[0069] Defoamer 0.1%

[0070] Infrared reflective titanium dioxide 8%

[0071] Kaolin 5%

[0072] Coalescent 3%

[0073] Antifreeze 3%

[0074] Protective Colloidal Salt 8%

[0075] Glass beads 15%

[0076] Film-forming emulsion 35%

[0077] Preservatives 0.2%

[0078] The composition of the weight ratio of each component of the protective sol:

[0079] Deionized water 95%

[0080] Protective Colloidal Salt 5%

[0081] The continuous phase varnish consists of the following co...

Embodiment 2

[0097] Example 2 Preparation of reflective and heat-insulating colorful coatings

[0098] This embodiment is composed of components in the following proportions, all in weight ratio, protective sol: dispersed phase base paint: continuous phase varnish = 20:50:50.

[0099] The composition of the weight ratio of each component of the dispersed phase base paint:

[0100] Deionized water 30%

[0101] Hydroxyethyl Cellulose 0.7%

[0102] PH regulator 0.3%

[0103] Dispersed wetting agent 0.6%

[0104] Defoamer 0.2%

[0105] Infrared reflective titanium dioxide 3%

[0106] Kaolin 3%

[0107] Coalescent 5%

[0108] Antifreeze 3%

[0109] Protective Colloidal Salt 8%

[0110] Glass beads 8%

[0111] Film-forming emulsion 38%

[0112] Preservatives 0.2%

[0113] The composition of the weight ratio of each component of the protective sol:

[0114] Deionized water 88%

[0115] Protective Colloidal Salt 12%

[0116] The continuous phase varnish consists of the following com...

Embodiment 3

[0132] Embodiment 3 performance test

[0133] In the above-mentioned embodiment 1 and embodiment 2, after spraying, the color dot particles on the surface of the board are randomly distributed and are in a relatively uniform state. Various colors of colored dot particles decorate the surface of the board, making the surface of the board present the surface texture of natural granite. According to the color and proportion of different color point particles, different natural stones can be imitated. Due to the inclusion of hollow glass microspheres, the surface of the coating has a sandy feel, making the paint film closer to the texture of natural stone.

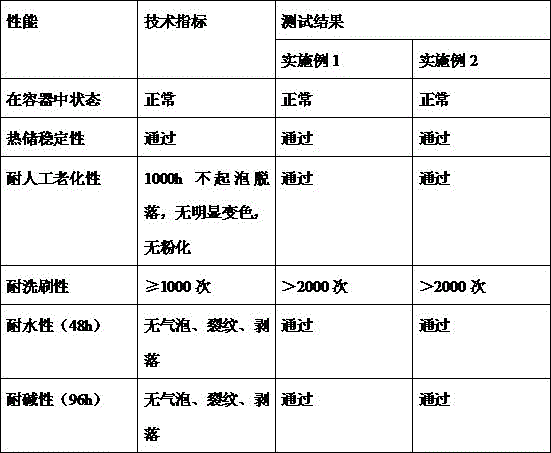

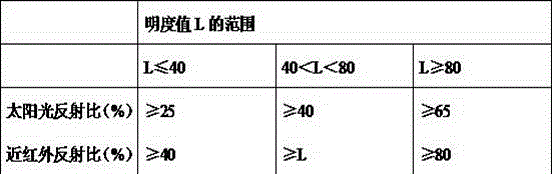

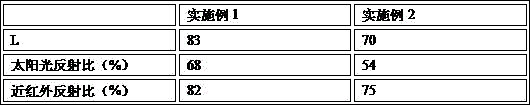

[0134] According to the standards of "HGT 4343-2012 Waterborne Colorful Architectural Coatings" and "JG / T 235-2008 Architectural Reflective and Heat-Insulating Coatings", Example 1 and Example 2 are tested, and the results are as follows:

[0135] Table 1 performance test result table

[0136]

[0137] It can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com