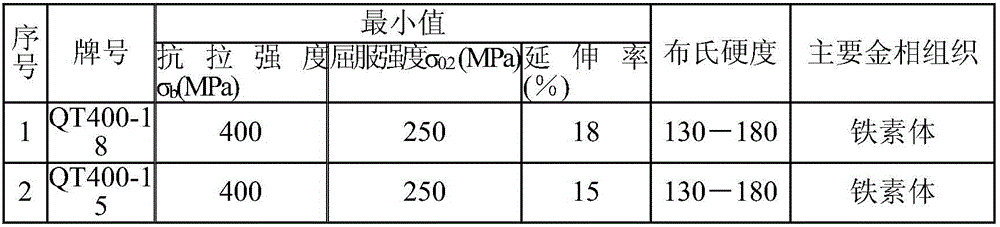

Light automobile steering gear aluminum alloy material replacing QT400 and gravity casting method of aluminum alloy material

A technology of automobile steering gear and aluminum alloy materials, which is applied in the field of aluminum alloy materials and their gravity casting, can solve the problems of low strength, low hardness, increased manufacturing cost, and failure to achieve the mechanical properties of ductile iron materials, etc., and achieve high product yield, Excellent casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method of an aluminum alloy material replacing a QT400 light-duty automobile steering gear, comprising the following steps:

[0060] (1) within the scope of the aforementioned Lewis acid-base pair and element ratio, select a group of material combinations, determine the weight ratio, and calculate the weight of each required material according to the total amount of alloy prepared as required;

[0061] (2) Add aluminum ingots or molten aluminum into the smelting furnace, heat and keep it above 700°C;

[0062] (3) Add manganese Mn, cadmium Cd, copper Cu, titanium Ti, stir, add selected Lewis acid-base pair, or add selected Lewis acid-base pair combination, and stir evenly;

[0063] (4) carrying out in-furnace refining to above-mentioned alloy melt then;

[0064] (5) After refining, remove slag, let it stand still, take samples to analyze the chemical composition of the alloy, and adjust the chemical composition to the specified deviation range according to...

Embodiment 1

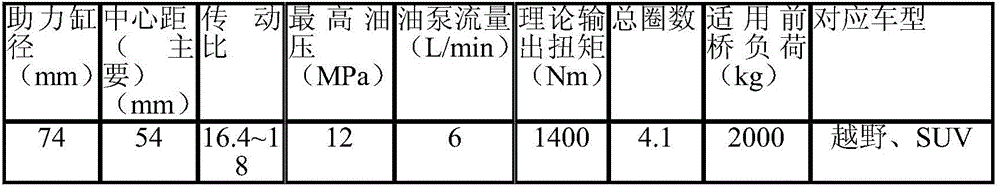

[0080] A kind of automobile K series aluminum alloy steering gear and its gravity casting method

[0081] 1. Steering gear parameters:

[0082]

[0083] 2. Production process: smelting → degassing → pouring → cooling → mold opening and picking → cleaning, sawing → solid solution → aging

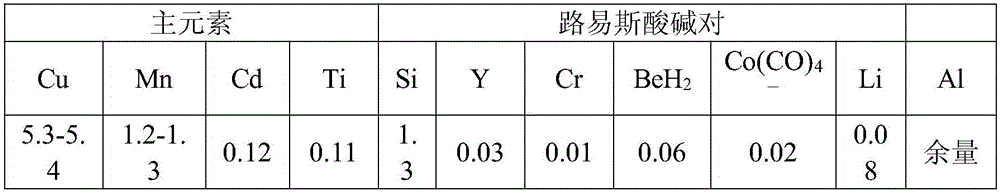

[0084] 3. Alloy formula

[0085] weight percentage (%)

[0086]

[0087] 4. The melt pouring temperature is 700-720°C;

[0088] 5. The mold preheating temperature is 320-400°C;

[0089] 6. Switch to pouring method, filling time is 8-12s;

[0090] 7. Cooling time: 240~360s;

[0091] 8. Solid solution temperature 530-550°C, heat preservation for 10 hours, rapid water cooling <10s, water temperature 40-55°C;

[0092] 9. The aging temperature is 145-175°C, heat preservation for 4 hours, and air cooling.

[0093] 10. The microstructure index of the casting: the metallographic structure is equiaxed grain, the average grain size is 40μm, and the number of combined phases (T+θH) in the g...

Embodiment 2

[0097] A kind of automobile M series aluminum alloy steering gear and its gravity casting method

[0098] 1. Steering gear parameters:

[0099]

[0100] 2. Production process: smelting → degassing → pouring → cooling → mold opening and picking → cleaning, sawing → solid solution → aging

[0101] 3. Alloy formula weight percentage (%)

[0102]

[0103] 4. Melt pouring temperature 710~740℃;

[0104] 5. The mold preheating temperature is 380-450°C;

[0105] 6. Tilting pouring method, the filling time is 12-15s;

[0106] 7. Cooling time: 240-400s;

[0107] 8. The solid solution temperature is 560-570°C, heat preservation for 8 hours, rapid water cooling <10s, water temperature 40-55°C;

[0108] 9. The aging temperature is 120-130 ℃, heat preservation for 6 hours, and air cooling.

[0109] 10. The microstructure index of the casting: the metallographic structure is equiaxed grain, the average grain size is 45μm, and the number of combined phases (T+θH) in the grain is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com