Continuous asphalt plant-mixing thermal regeneration mixture pre-mixing machine

A ready-mixer and thermal regeneration technology, which is applied in roads, road repairs, roads, etc., can solve problems such as difficulty in equipment installation, increase in the overall height of equipment, and loss of mixture temperature, so as to reduce the overall height and installation difficulty, and avoid The effect of flue gas leakage and increased feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical scheme and advantages of the present invention clearer, the following reference Attached picture Examples are also given to further describe the present invention in detail.

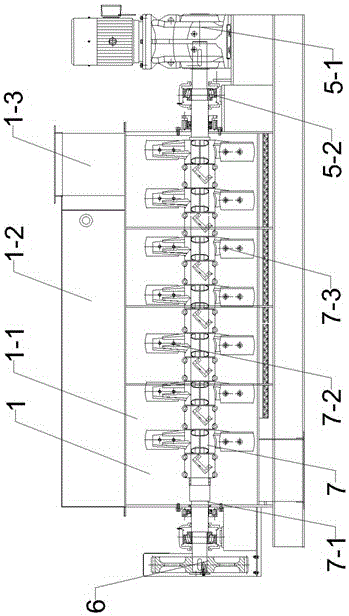

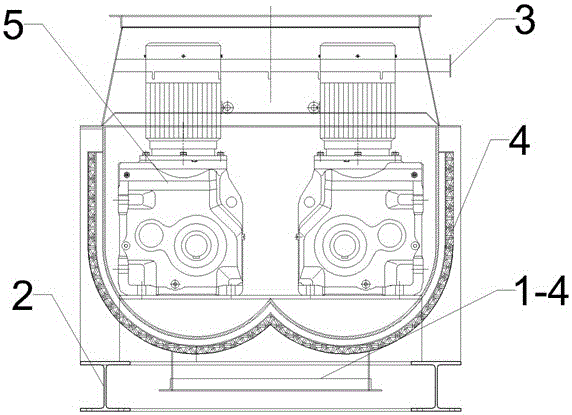

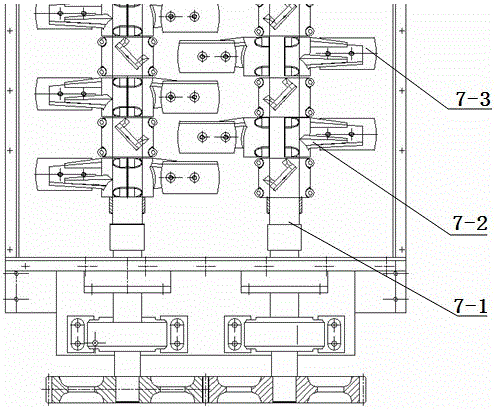

[0022] refer to picture 1 , picture 2 and picture 3 , a kind of continuous asphalt factory mixed hot recycled mixture premixer, including premixer main body 1, stirring device 7, driving device 5 and regeneration agent spraying device; premixer main body 1 includes support seat 2 and is located at support seat 2 The mixing tank 1-1 on the top is provided with a cover plate 1-2, a feed port 1-3 and a discharge port 1-4 on the mixing tank 1-1; the stirring device 7 includes two stirring shafts 7-1, and the stirring shaft 7-1 is connected with the driving device 5, the stirring shaft 7-1 is axially provided with a plurality of stirring arms, and the stirring arm 7-2 is provided with stirring teeth 7-3, wherein the arrangement direction of the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com