Lubricating cooling system for vehicle gear box

A lubricating cooling, gear box technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of poor gravity oil return, oil leakage, high oil viscosity, etc. life, reducing oil viscosity, reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

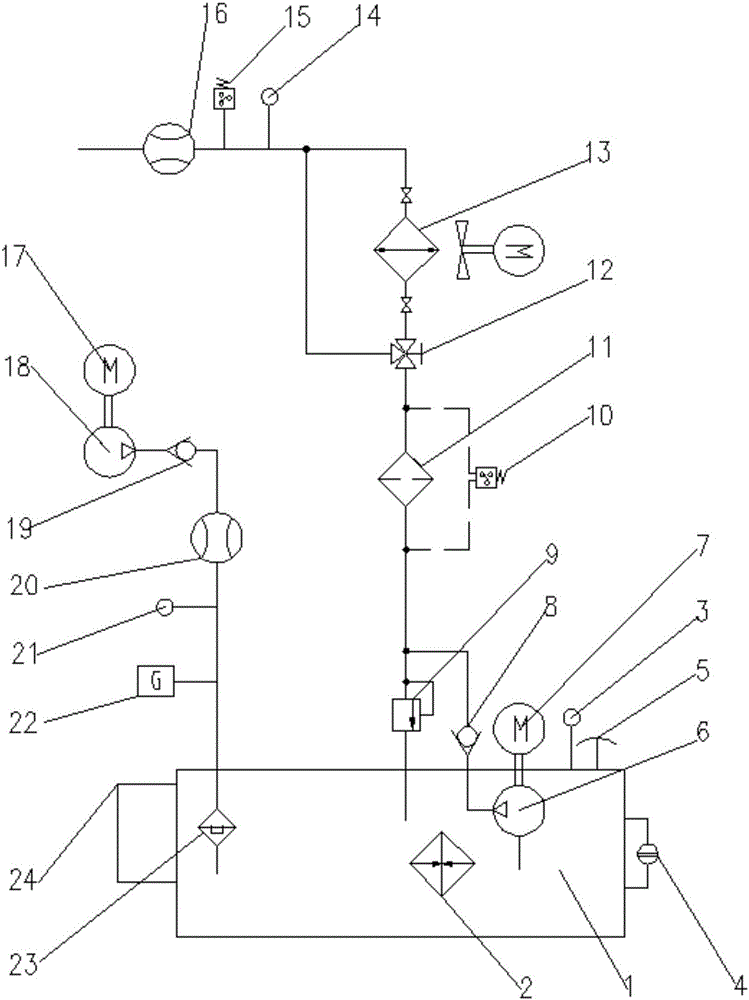

[0049] Such as figure 1 As shown, the present invention provides a lubricating and cooling system for a vehicle gearbox, comprising: an oil tank 1, an oil inlet pump 6, a first variable frequency motor 7, a first temperature sensor 3, an oil return pump 18, a second variable frequency motor 17 and controller 24.

[0050] The first frequency conversion motor 7 is used to drive the oil inlet pump 6 to extract oil from the oil tank 1, and the extracted oil is input to the oil inlet of the vehicle gearbox through the oil inlet pipeline; wherein, the oil is used for Lubricating fluid for lubricating and cooling vehicle gearboxes, the oil is very viscous at low temperatures. The oil mentioned in the present invention refers to lubricating oil used for lubricating the gearbox of a vehicle.

[0051] The first temperature sensor 3 is arranged in the oil tank for measuring the temperature of the oil in the oil tank 1 .

[0052] The second variable frequency motor 17 is used to drive ...

Embodiment 2

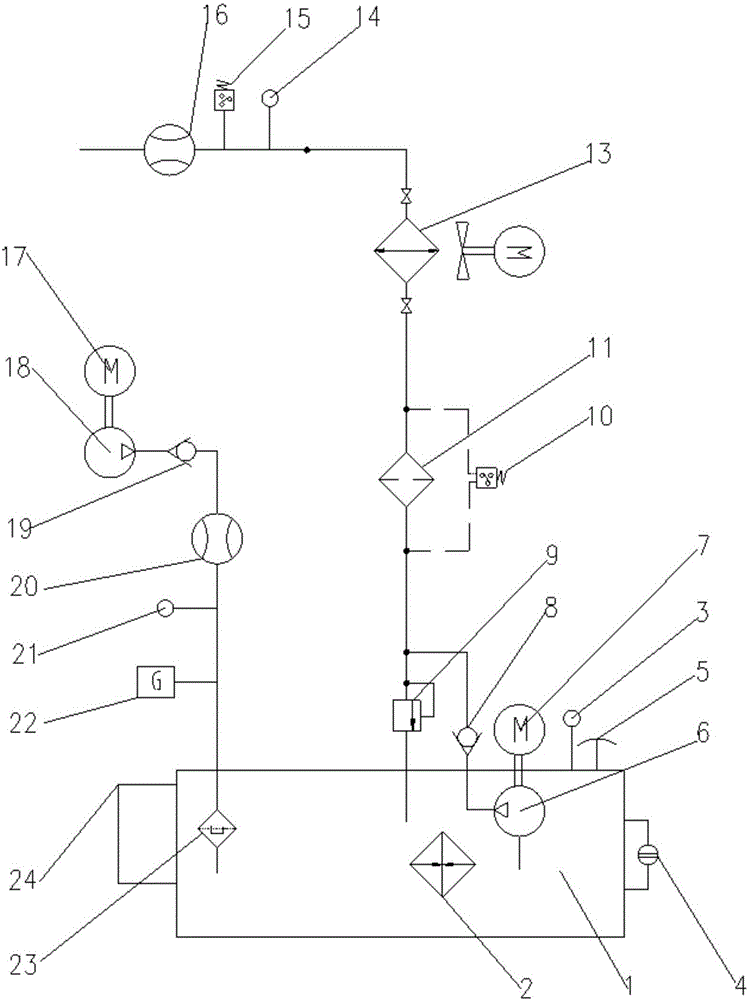

[0073] Such as figure 2 As shown, the present invention provides another lubricating and cooling system for a vehicle gearbox, including: an oil tank 1, an oil inlet pump 6, a first variable frequency motor 7, a first temperature sensor 3, an oil return pump 18, and a second variable frequency motor 17 and controller 24 .

[0074] The first frequency conversion motor 7 is used to drive the oil inlet pump 6 to extract oil from the oil tank 1, and the extracted oil is input to the oil inlet of the vehicle gearbox through the oil inlet pipeline; wherein, the oil is used for Lubricating fluid for lubricating and cooling vehicle gearboxes, the oil is very viscous at low temperatures.

[0075] The first temperature sensor 3 is arranged in the oil tank for measuring the temperature of the oil in the oil tank 1 .

[0076] The second variable frequency motor 17 is used to drive the oil return pump 18 to extract the oil in the vehicle gearbox, and the extracted oil enters the oil tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com