Large-power xenon lamp bulb and preparation method thereof

A high-power, xenon technology, applied in the field of xenon lamps, can solve the problems of loss of light source, affecting luminous efficiency, affecting service life, etc., to achieve the effects of uniform and controllable thickness, uniform surface temperature, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution will be described in detail below in conjunction with specific embodiments.

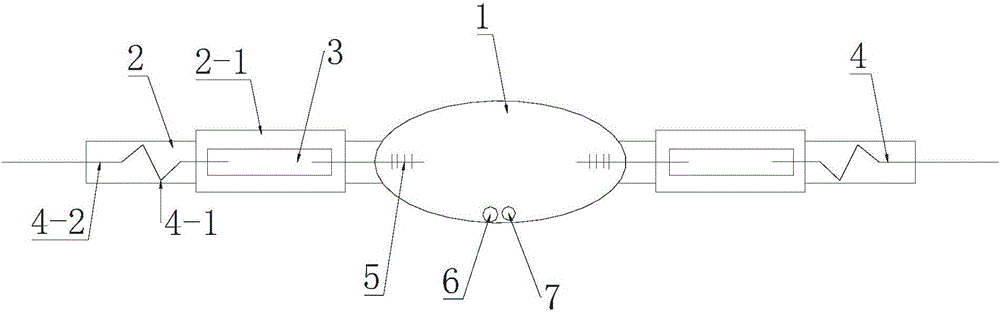

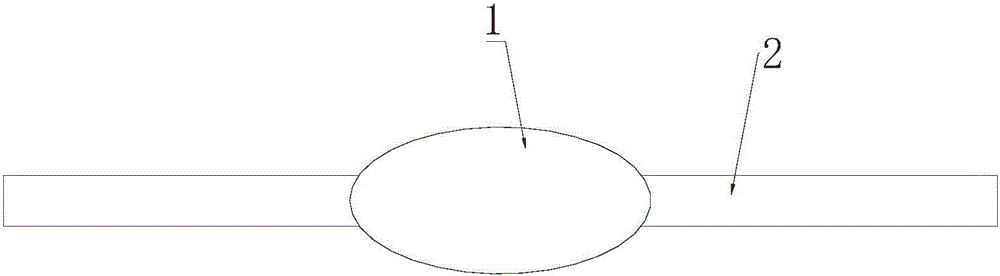

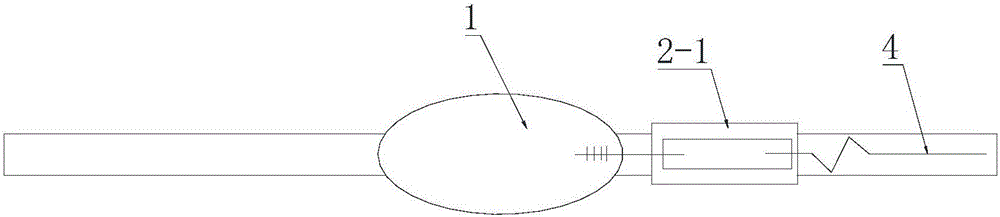

[0028] like figure 1 As shown, the present invention is a high-power xenon bulb, including a bulb 1, which is an olive-shaped glass bulb. Glass tubes 2 are arranged on both sides of the bulb 1, and molybdenum rods 4 with molybdenum sheets 3 are arranged inside the glass tubes 2. Electrode tips 5 are arranged at the ends of the molybdenum rods 4. The bulbs are filled with xenon gas, metal halide 6 and mercury 7, the glass tube 2 is provided with a clamping position 2-1 for fixing the molybdenum rod, and the molybdenum rod is provided with a limit lamp pin 4-1 that presses against the inner walls of both sides of the glass tube. The limit light foot 4-1 includes an S-shaped support bent by a molybdenum rod. The two sides of the S-shaped support are respectively pressed against the inner wall of the glass tube. Section 4-2. Of course, the S-shaped support can also be rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com