Winterization method of oil-tea camellia seed oil

A technology of winterization of camellia oleifera seed oil, applied in the field of winterization, can solve the problems of poor winterization effect, waste, and increased processing cost of camellia oleifera seed oil, achieve good crystallization effect, reduce cost increase and loss, and improve crystallization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

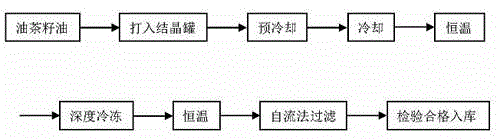

Method used

Image

Examples

Embodiment 1

[0033] Put the camellia seed oil with an initial oil temperature of 28°C into the crystallization tank for rapid pre-cooling, the cooling time is 85 minutes, and the temperature after rapid cooling is 17.8°C; the pre-cooled camellia seed oil is continuously cooled at a uniform speed The temperature is 30min / °C. When the temperature is lowered to 4.2°C, the temperature is then kept constant. When the temperature is constant, the temperature rises no more than 0.5°C, and the constant temperature time is 120min. The Camellia oleifera seed oil after constant temperature is deep-frozen, the cooling rate is 60min / °C, the final cooling temperature is -3.8°C, the temperature rises at constant temperature does not exceed 0.3°C, and the constant temperature time is 580min; Camellia oleifera seed oil is filtered, and the distance between the inlet of the filter and the oil outlet of the crystallization tank is 4.7m. When filtering, the camellia oleifera seed oil is kept at a constant temp...

Embodiment 2

[0035] Pour the camellia seed oil with an initial oil temperature of 25°C into the crystallization tank for rapid pre-cooling. The cooling time is 80 minutes, and the temperature after rapid cooling is 18°C; the pre-cooled camellia seed oil is continuously cooled at a uniform speed. The temperature is 30min / °C. When the temperature is lowered to 4°C, the temperature is then kept constant. When the temperature is constant, the temperature rises no more than 0.5°C, and the constant temperature time is 120min. After constant temperature, deep-freezing camellia seed oil, the cooling rate is 60min / °C, the final cooling temperature is -4°C, the temperature rises no more than 0.3°C during constant temperature, and the constant temperature time is 580min; Camellia oleifera seed oil is filtered, and the distance between the inlet of the filter and the oil outlet of the crystallization tank is 5m. When filtering, the camellia oleifera seed oil is kept at a constant temperature, and the f...

Embodiment 3

[0037] Put the camellia seed oil with an initial oil temperature of 20°C into the crystallization tank for rapid pre-cooling, the cooling time is 75 minutes, and the temperature after rapid cooling is 18.2°C; the pre-cooled camellia seed oil is continuously cooled at a uniform speed The temperature is 30min / °C. When the temperature is lowered to 3.8°C, the temperature is then kept constant. When the temperature is constant, the temperature rises no more than 0.5°C, and the constant temperature time is 120min. The Camellia oleifera seed oil after constant temperature is deep-frozen, the cooling rate is 60min / °C, the final cooling temperature is -4.2°C, the temperature rises at constant temperature does not exceed 0.3°C, and the constant temperature time is 580min; Camellia oleifera seed oil is filtered, and the distance between the inlet of the filter and the oil outlet of the crystallization tank is 5.3m. When filtering, the camellia oleifera seed oil is kept at a constant temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com