A cooling device for a high-speed tin coating machine

A technology of cooling device and tin coating machine, which is applied in the direction of coating, metal material coating process, hot-dip plating process, etc. It can solve the problems of small temperature drop, incomplete solidification of surface tin, and reduced product quality and work efficiency. Achieve the effect of improving production efficiency and solving the instability of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

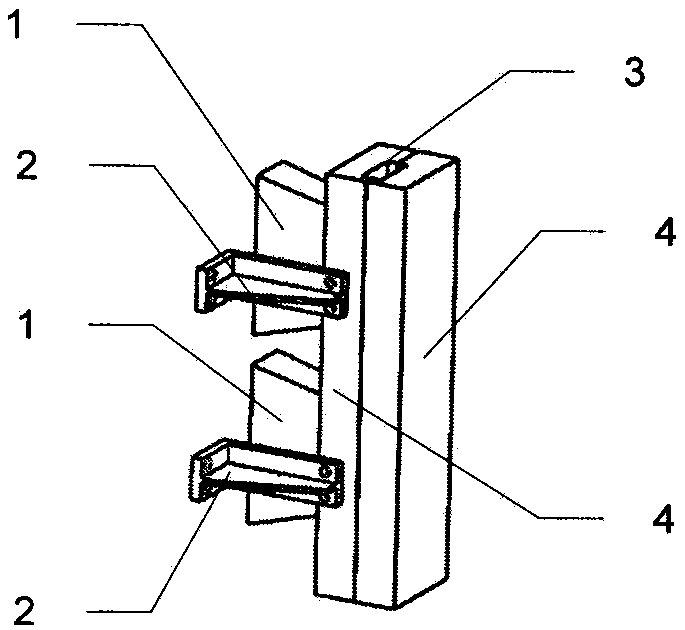

[0015] Such as figure 1 , the cooling device in the embodiment of the present invention mainly includes a fan 1, a cooling pipe mounting frame 2, and two cooling boxes 4 spliced together. The strip passes through. The mounting bracket 2 mainly plays the role of installation and fixation, and is connected with the cooling pipe 4 and the tin coating machine body by bolts, the fan 1 is installed on the machine body, and the ventilation box is directly connected with the No. 1 air inlet 6.

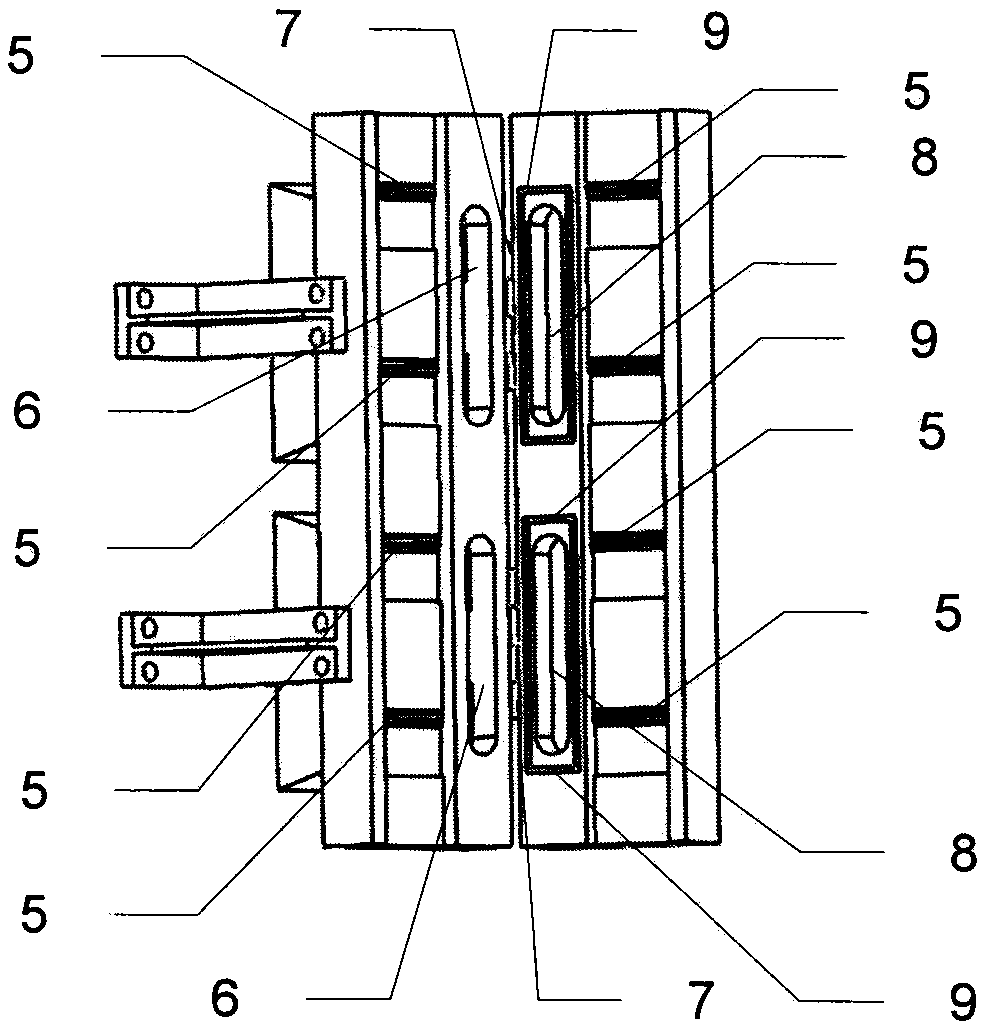

[0016] Such as figure 2 , the two cooling boxes 4 are opened and closed through the hinge 7, when the cooling box 4 is closed, the No. 1 air inlet 6 and the No. 2 air inlet 8 coincide, and the two air inlets are sealed by the sealing ring 9 to prevent the cold air from leaking, so as to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com