Continuous extrusion cooling device for cable material processing

A cooling device and cable material technology, applied in the direction of coating, etc., can solve the problems of poor cooling uniformity and cooling effect, and achieve the effect of improving cooling effect, improving quality, uniform and rapid cooling, shaping and granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

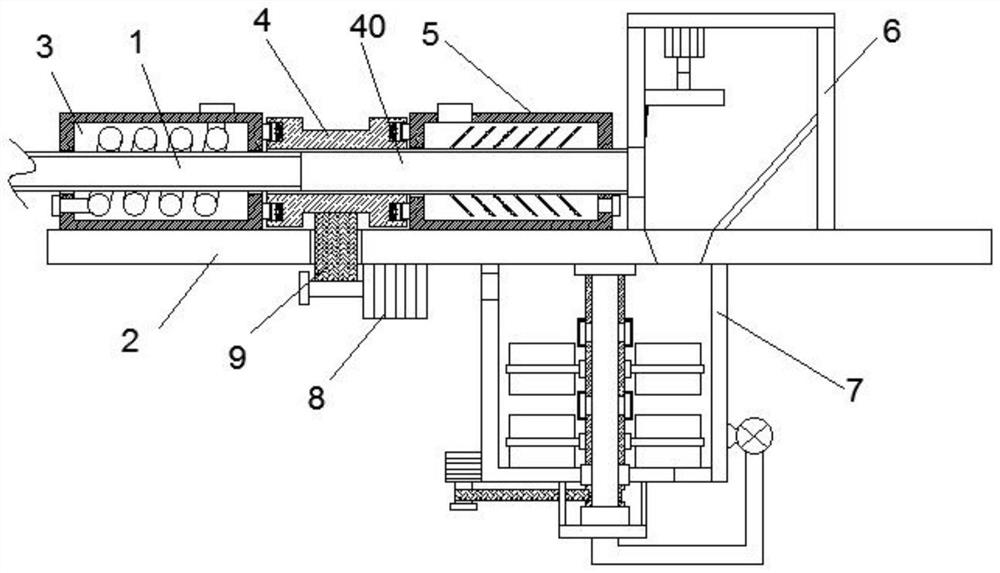

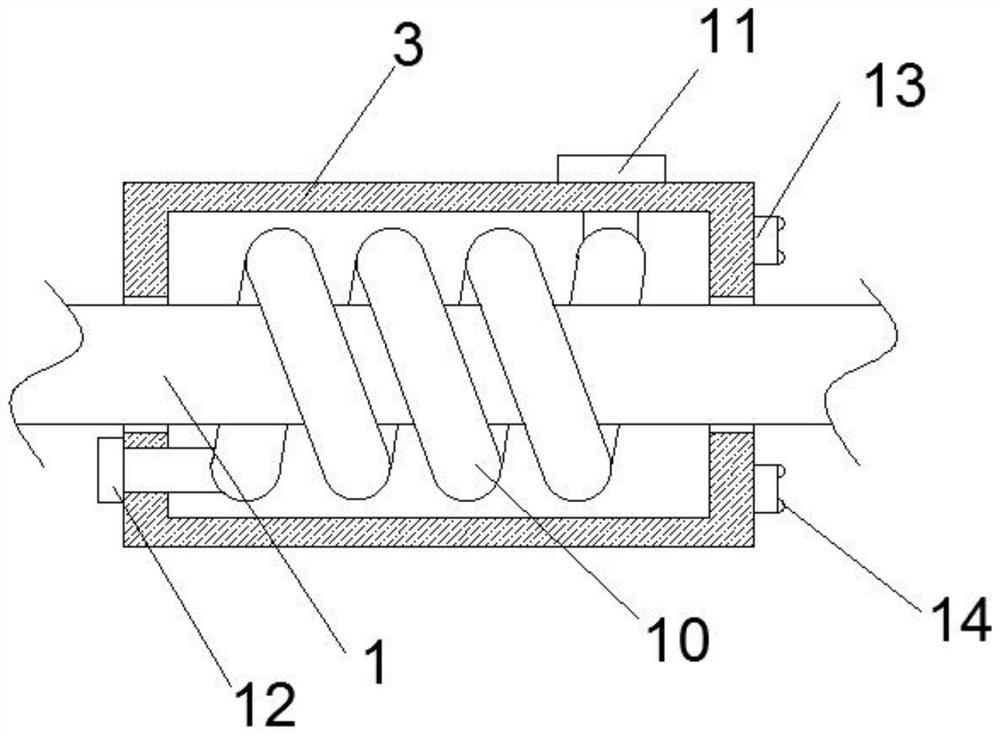

[0030] refer to Figure 1-6 , a continuous extrusion cooling device for cable material processing, comprising a device table 2, a water-cooled box 3, a separation box 4, an air-cooled box 5 and a pelletizing frame 6 arranged sequentially from left to right on the device table 2, said The left side of the upper end of the device table 2 is provided with an extruding tube 1, and the left end of the extruding tube 1 is connected with the extruding device. The inside of the water-cooled box 3 is spirally provided with a spiral tube 10, and the two ends of the spiral tube 10 are connected to the water-cooled box 3 respectively. The external water inlet 11 communicates with the water outlet 12. The inside of the separation box 4 is provided with a material transfer pipe 40, and the right end of the material transfer pipe 40 extends outwards through the air-cooled box 5 and is connected with the pelletizing frame 6. The right end of the extrusion pipe 1 passes through the spiral pipe...

Embodiment 2

[0033] refer to Figure 1-6 , this embodiment is basically the same as Embodiment 1. Preferably, the lower end of the device table 2 is provided with a first motor 8, and the output shaft of the first motor 8 is connected to the outer wall of the separation box 4 through the first belt 9, and the separation The two sides of the box 4 are connected with the water-cooled box 3 and the air-cooled box 5 by a rotating mechanism, which effectively causes rotation between the separation box 4 and the extruded material. Improve the cooling effect and improve the uniformity of cooling.

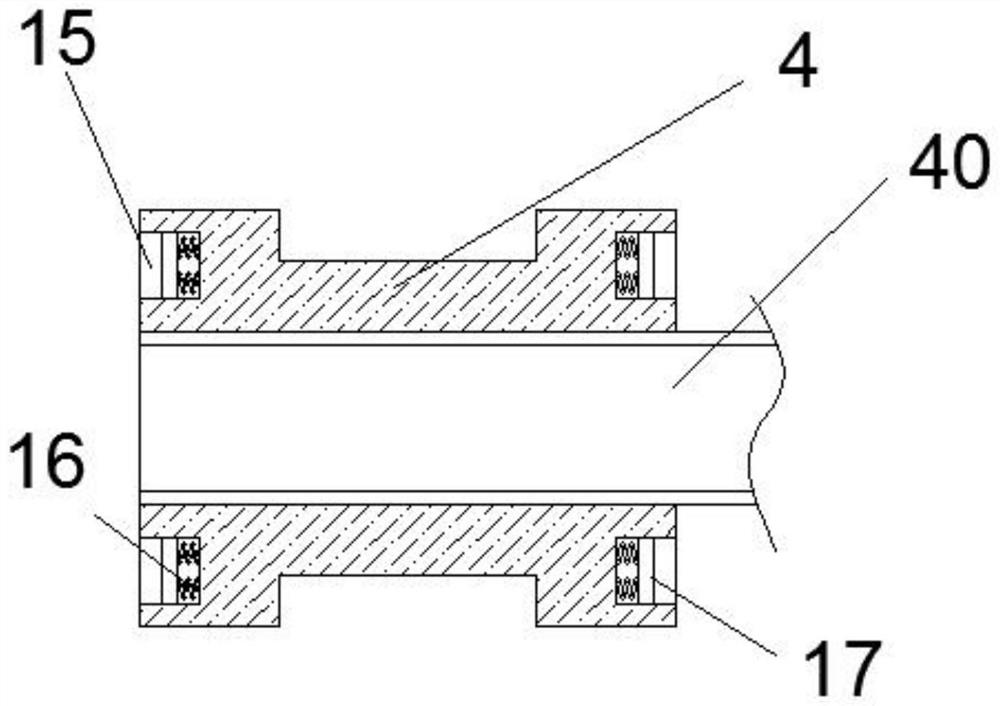

[0034] In order to improve the stability of the rotation of the separation box 4, preferably, the rotating mechanism includes annular slots 15 arranged on the outer walls of both sides of the separation box 4 and a plurality of slots arranged on the side of the separation box 4 near the water-cooled box 3 and the air-cooled box 5. A block 13, the inside of the annular slot 15 is connected with an extr...

Embodiment 3

[0037] refer to Figure 1-6 , this embodiment is basically the same as Embodiment 2. Preferably, the lower end of the telescopic rod 23 is connected to the limiting plate 24, the cutting blade 25 is arranged at the bottom of the limiting plate 24, and one side of the limiting plate 24 is connected to the pelletizing frame. 6 sliding connections on the inner wall. Effectively guarantee the stability of the cutting process.

[0038] In order to facilitate the cut extruded material to quickly fall into the cold barrel 7 below, preferably, an inclined plate 26 is provided at the inner right end of the pelletizing frame 6 , and the inclined plate 26 is connected with the discharge port 27 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com