Cooling method of high strength band steel and device

A cooling device and cooling method technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of low average cooling speed, low average cooling speed, and reduced cooling speed, and achieve uniform and rapid cooling of product surfaces quality, eliminate uneven cooling, and improve cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

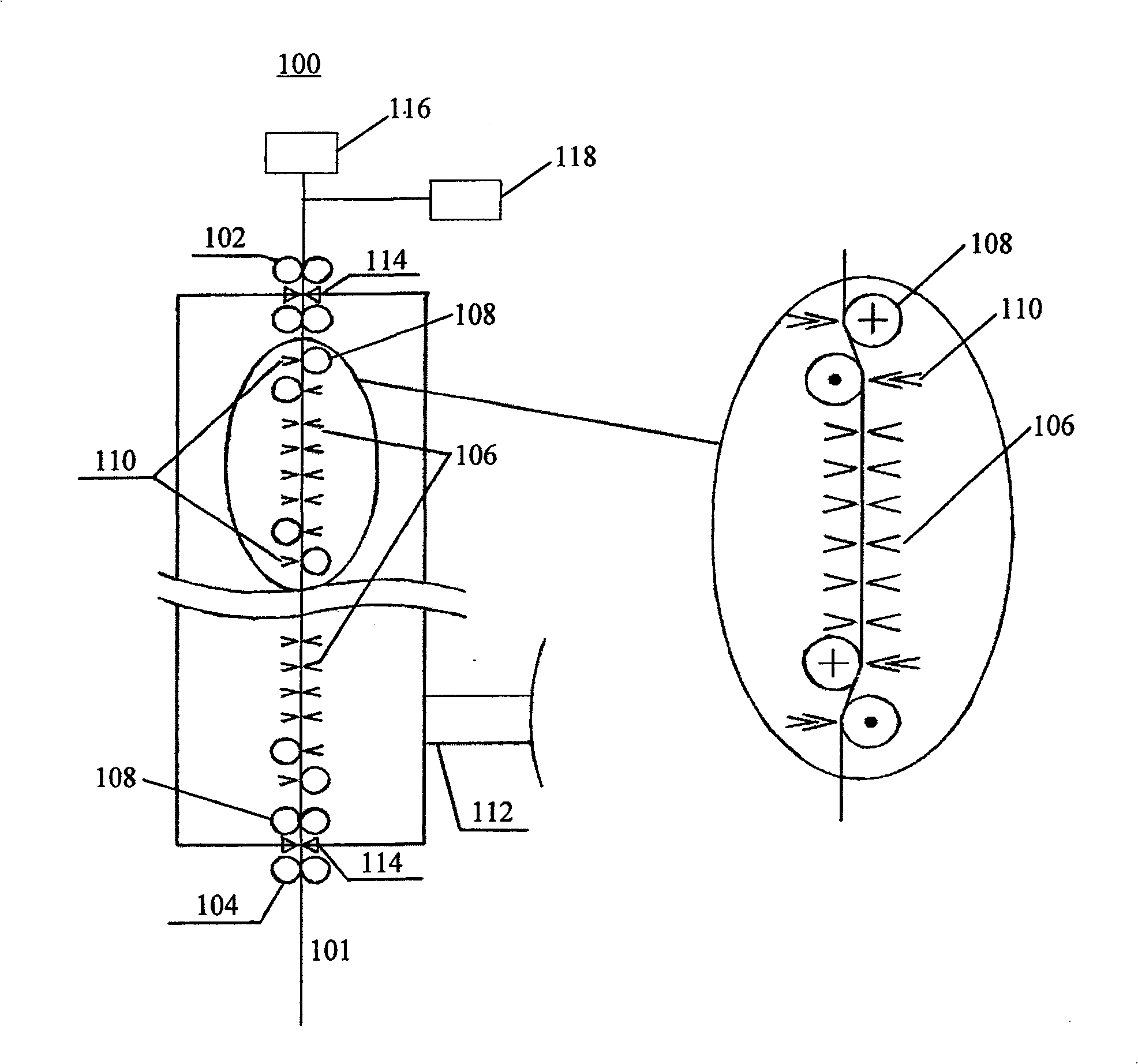

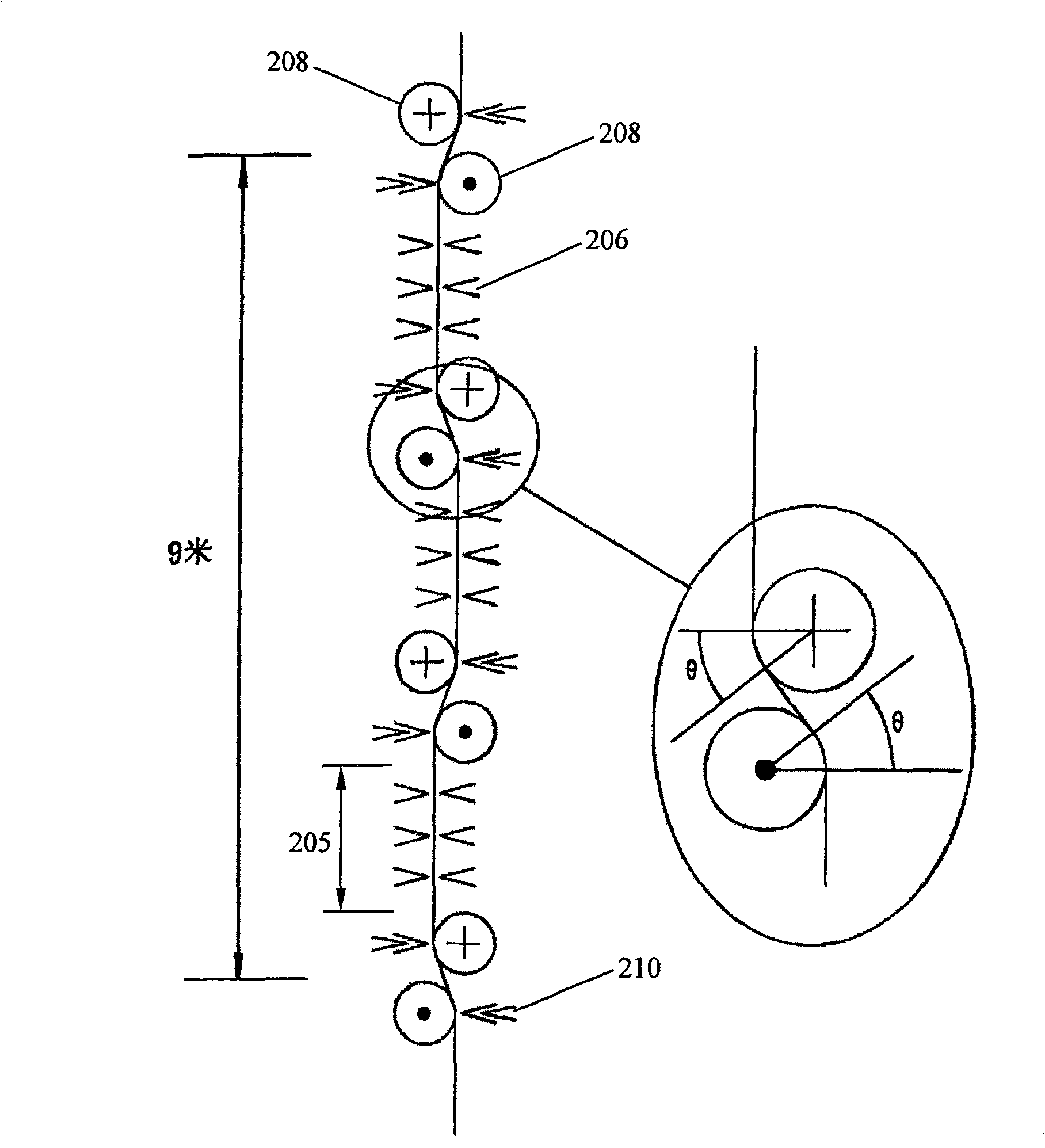

[0053] Example 1, the total length of the cooling zone combined with high hydrogen jet cooling and roller cooling is 9m, and the thickness of the strip to be cooled is 0.8mm. When the high-temperature strip steel after soaking and slow cooling enters the combined cooling zone of the present invention through the pinch rolls, the wrapping angle of the strip steel and each water-cooled stabilizing roll is basically the same, and by controlling the water-cooled rolls to insert The depth stabilizes the wrap angle θ at about 60°. At the same time, the high-hydrogen nozzle sprays a protective gas with a hydrogen concentration of about 75% at a high speed at a flow rate of about 140m / s to the surface of the high-temperature strip in operation to rapidly cool the strip. The ultra-high-speed and large-flow back-blowing airflow velocity at the wrap angle of the steel and water-cooled stabilizing roll can be greater than 150m / s (for example, 170m / s), so that the strip can be fully cooled,...

example 2

[0055] Example 2, the thickness of the strip to be cooled is 1.5mm. When the high-temperature strip steel after soaking and slow cooling enters the patented combined cooling zone of high-hydrogen high-speed jet cooling and roll cooling through the pinch rolls, the wrap angles of the strip steel and each water-cooled stabilizing roll are basically the same, and the insertion of the water-cooled rolls is controlled The depth stabilizes the wrapping angle θ at about 70°. At the same time, the high-hydrogen nozzle sprays a protective gas with a hydrogen concentration of about 80% at a high speed at a flow rate of 160m / s to the surface of the running high-temperature strip to rapidly cool the strip. The ultra-high-speed and large-flow back-blowing airflow velocity of 190m / s at the wrap angle of the water-cooled stabilizing roll greatly improves the average cooling rate of the strip. Because the strip steel is relatively thick, a lower strip speed V=180mpm=3m / s is adopted. At this t...

example 3

[0057] Example 3, the strip thickness to be cooled is 1.2mm. When the high-temperature strip steel after soaking and slow cooling enters the patented combined cooling zone of high-hydrogen high-speed jet cooling and roll cooling through the pinch rolls, the wrap angles of the strip steel and each water-cooled stabilizing roll are basically the same, and the insertion of the water-cooled rolls is controlled The depth stabilizes the wrapping angle θ at about 65°. At the same time, the high-hydrogen nozzle sprays a protective gas with a hydrogen concentration of about 75% at a high speed at a flow rate of 150m / s to the surface of the running high-temperature strip to rapidly cool the strip, and set it on the strip The ultra-high-speed and large-flow back-blowing airflow at the wrap angle of the water-cooled stabilizing roll is 180m / s. At this time, the medium belt speed V=240mpm=4m / s is adopted. At this time, the three-stage high hydrogen jet cooling section, roll cooling and bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com