Sc/Ce-codoped lutetium silicate and lutetium yttrium silicate crystals and melt-process growth method thereof

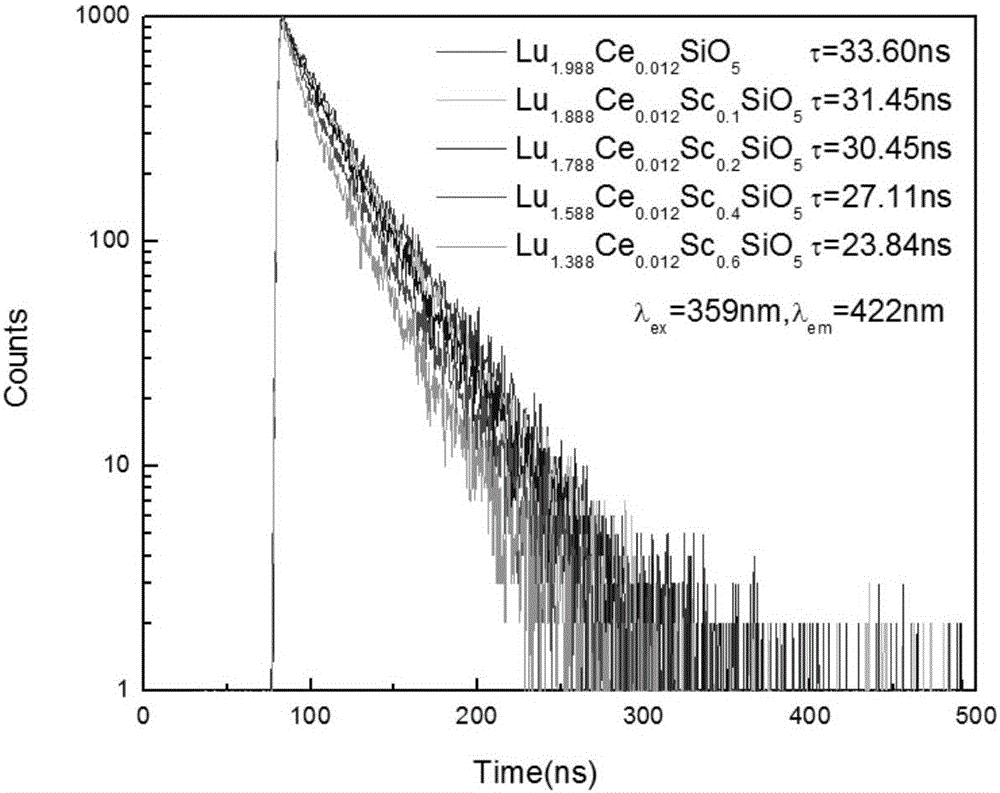

A technology of yttrium lutetium silicate and growth method, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor energy resolution and strong background radiation, and achieve the goal of improving time resolution and accelerating lifespan Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

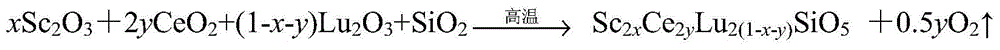

[0025] Example 1 Growth of Sc 2x Ce 2y Lu 2(1-x-y) SiO 5 the crystal

[0026] Take x=0.1, y=0.0015 to grow Sc 2x Ce 2y Lu 2(1-x-y) SiO 5 Crystal, assuming that the raw material required for crystal growth is 100g, the crystal growth method of the melt method is as follows:

[0027] (1) Using Sc 2 o 3 , CeO 2 、Lu 2 o 3 , SiO 2 As a raw material, according to the chemical reaction formula: Carry out batching, take by weighing 3.19g Sc altogether in this proportion 2 o 3 , 0.12g CeO 2 , 82.78g Lu 2 o 3 , 13.91g SiO 2 Fully mix evenly to obtain the ingredient mixture;

[0028] (2) pressing the mixture into a round cake, and calcining at 1300° C. for 96 hours to obtain the initial raw material for crystal growth;

[0029] (3) Put the initial raw material for crystal growth into the growth iridium crucible, use the JGD600 single crystal furnace system, heat and fully melt through intermediate frequency induction to obtain the initial melt for crystal growth; ...

Embodiment 2

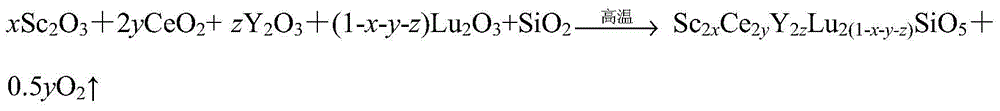

[0030] Example 2 Growth of Sc 2x Ce 2y Y 2z Lu 2(1-x-y-z) SiO 5 the crystal

[0031] Take x=0.1, y=0.0015, z=0.2 to grow Sc 2x Ce 2y Y 2z Lu 2(1-x-y-z) SiO 5 Crystal, assuming that the raw material required for crystal growth is 100g, the crystal growth method of the melt method is as follows:

[0032] (1) Using Sc 2 o 3 , CeO 2 、Lu 2 o 3 , SiO 2 As a raw material, according to the chemical reaction formula: Carry out batching, take by weighing 3.50g Sc altogether according to this ratio 2 o 3 , 0.13g CeO 2 , 69.66g Lu 2 o 3 , 11.46g Y 2 o 3 , 15.24g SiO 2 Fully mix evenly to obtain the ingredient mixture;

[0033] (2) pressing the mixture into a round cake, and calcining at 1300° C. for 96 hours to obtain the initial raw material for crystal growth;

[0034] (3) Put the initial raw material for crystal growth into the growth iridium crucible, use the JGD600 single crystal furnace system, heat and fully melt through intermediate frequency inductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com