Car-carrying plate stacking machine and intelligent stereo garage using car-carrying plate stacking machine

A technology of three-dimensional garages and car-carrying boards, applied in the field of car-carrying board palletizers, can solve problems such as inability to turn, complicated equipment installation, difficult disassembly and replacement, etc., to achieve improved storage efficiency, fast access to cars, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

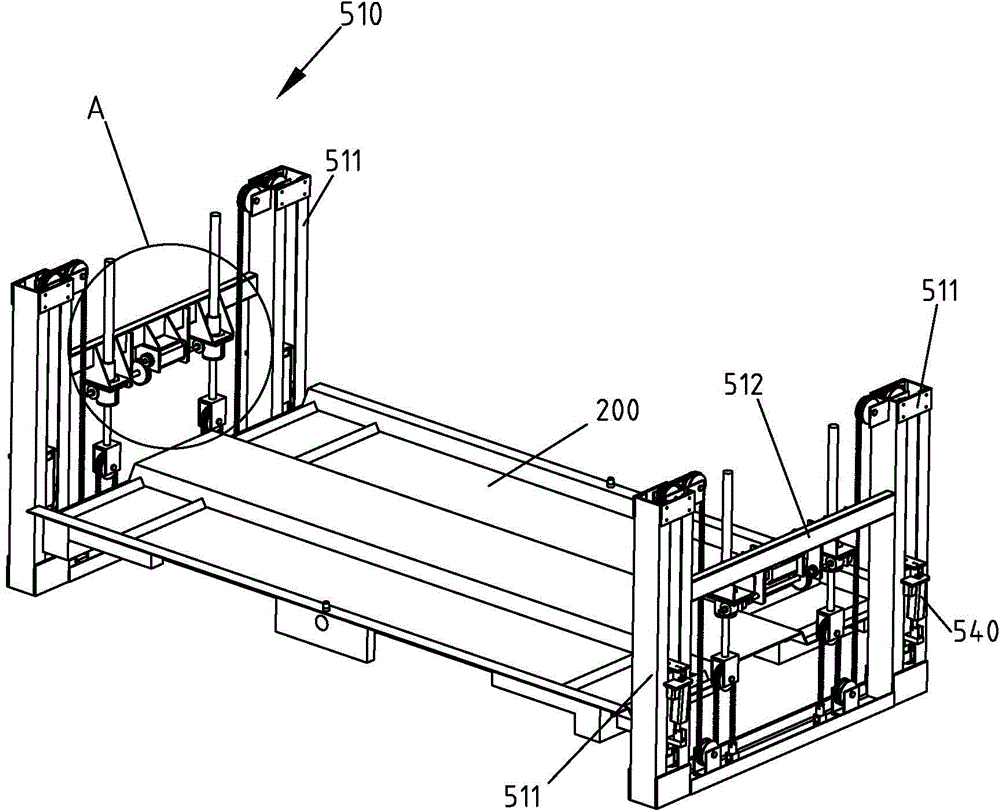

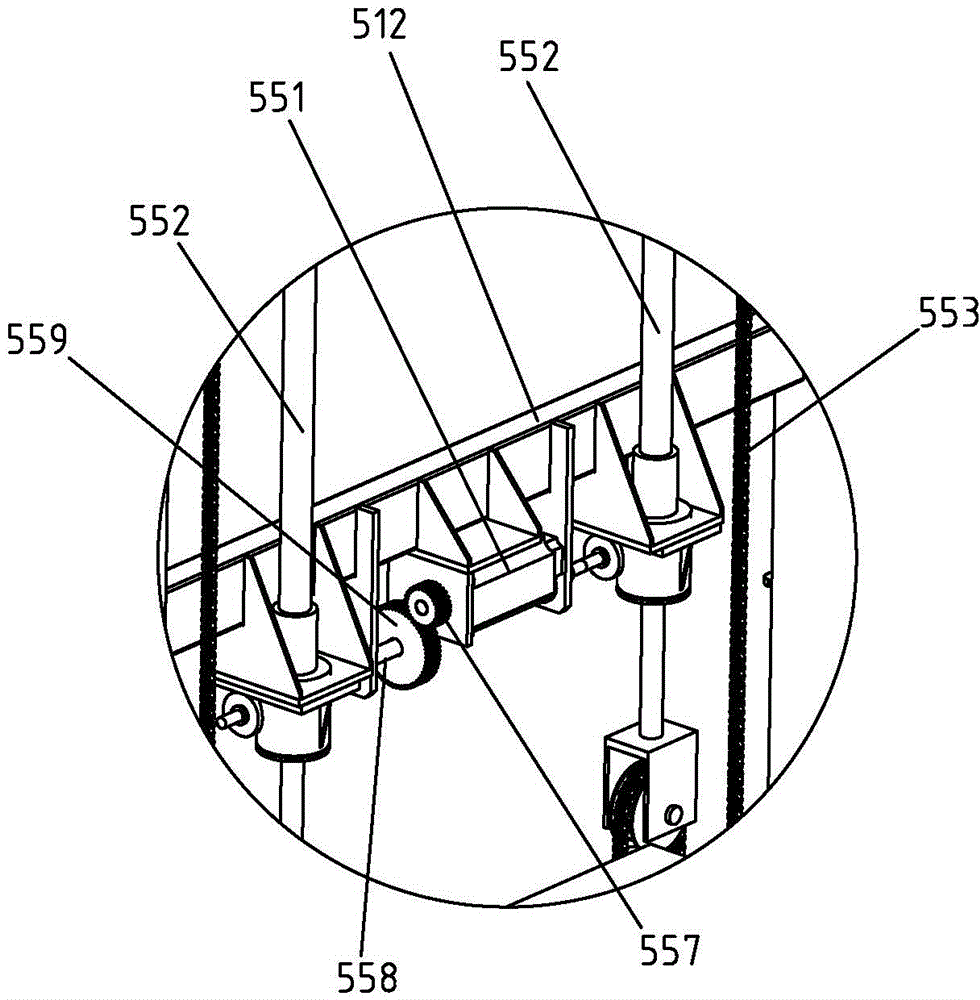

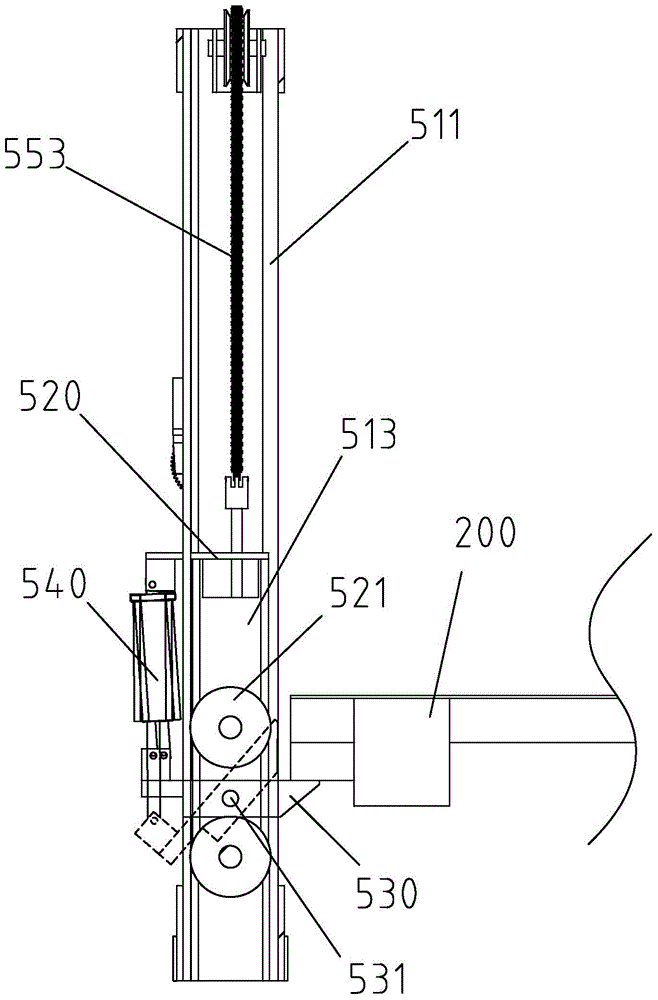

[0029] see Figure 1 to Figure 7 According to the embodiment of the palletizer 500 provided by the present invention, it includes two opposite supports 510, a lifter 600 set on the supports 510 and a lifter 520 driven by the lifter 600. The frame 520 is provided with a lift lock hook 530, and the lift lock hook 530 is rotatably installed on the lift frame 520 through a rotating shaft 531. The lift frame 520 is provided with a telescopic mechanism 540, and the lift lock hook 530 One end is connected with the telescoping mechanism 540 to drive the other end of the lifting hook 530 to swing. The telescoping mechanism 540 in this embodiment is an electric cylinder. The present invention has simple structure, few parts, and convenient assembly; the lifting hooks 530 on the two brackets 510 cooperate to lift or lower the vehicle-carrying plate 200 on the vehicle-carrying plate palletizer 500 for palletizing, and are easy to use. During specific use, when the four electric cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com