Fully glued photovoltaic junction box with ventilation on three sides of the bottom and internal diodes inverted and suspended

An internal diode and volt junction box technology, applied in the field of photovoltaics, can solve problems such as box deformation, rainwater infiltration, affecting the life and performance of the junction box, and achieve the effects of improving heat dissipation efficiency, increasing air convection, and avoiding burnt failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

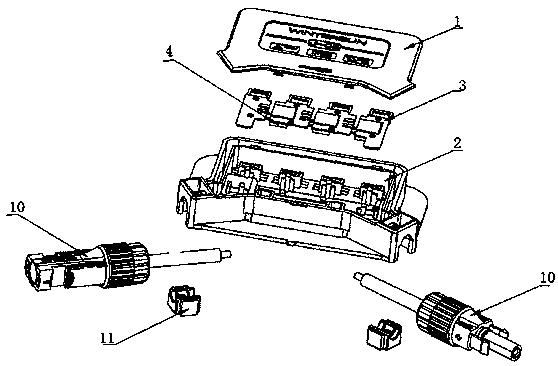

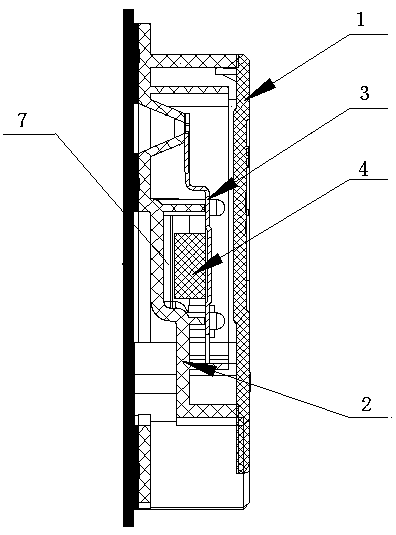

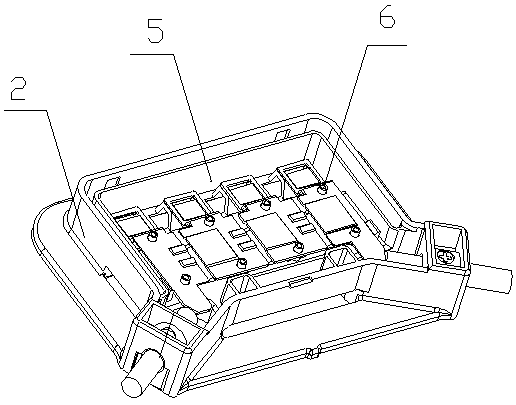

[0019] see figure 1 — Figure 4 As shown, in this embodiment, a fully glued photovoltaic junction box with three sides of the bottom ventilated and internal diodes suspended upside down includes an upper cover 1 and a casing 2 that can be fastened together, as well as metal conductors 3, diodes 4 and wires. cable 10, the diode 4 is installed on the back of the metal conductor 3, and the front of the diode 4 faces downward, and a housing cavity 5 that can accommodate the metal conductor 3 and the diode 4 is formed in the housing 2, and in the housing cavity 5 A plurality of positioning columns 6 are arranged on the bottom plate, positioning holes corresponding to the positioning columns 6 are opened on the metal conductor 3, and a sunken groove 7 is opened on the bottom plate of the accommodating cavity 5 directly below the diode 4, The range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com