Lawn mower

A lawn mower and mowing technology, which is applied to the chassis of harvesters, cutters, and agricultural machinery, etc., can solve the problems of low transmission efficiency, high cost, and air pollution, so as to reduce energy consumption and maintenance costs, and ensure control Accuracy and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

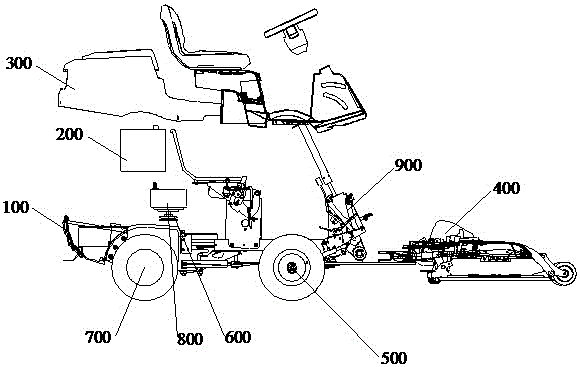

[0061] A lawn mower, including a frame system, a walking system, a power system, an operating system 900 , an electrical control system 200 and a header system 400 .

[0062] The rack system includes a front rack 500 and a rear rack 100 connected together.

[0063] The rear frame 100 is formed by riveting two castings and includes a mounting plate for assembling the electrical control system.

[0064] There is an outer covering system 300 above the rack system, and the front rack 500 and the rear rack 100 are connected and then assembled with the outer covering system 300 .

[0065] The exterior covering system 300 includes a rear frame shell, a front frame shell, a seat assembly and a steering wheel, the rear frame shell and the front frame shell are respectively mounted on the rear frame assembly and the front frame assembly , and then install the seat assembly and steering wheel on the shell.

[0066] The walking system is assembled on the frame system to realize the forw...

Embodiment 2

[0089] A lawn mower, including a frame system, a walking system, a power system, an operating system 900 , an electrical control system 200 and a header system 400 .

[0090] Lithium battery pack, electrical control system 200, header system 400, mowing motor 800, transmission mechanism 600 and rear axle mechanism 700 are assembled on the rear frame 100 and the front frame 500 respectively.

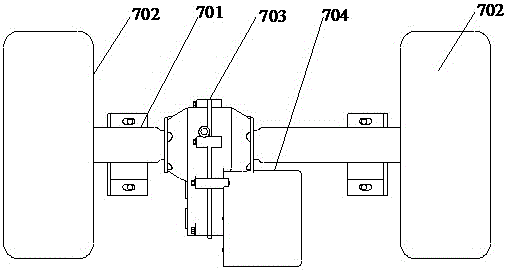

[0091] The transmission mechanism 600 in the preferred embodiment 1 is connected with the mowing motor 800 , and the mowing motor 800 is fixed on the motor mounting plate 801 .

[0092] The transmission mechanism 600 includes a first pulley 601 connected to the mowing motor 800, the output end of the first pulley 601 is connected to the input end of the first transmission belt 602, and the output end of the first transmission belt 602 is connected to the second pulley 603 , the second pulley 603 is connected with the third pulley 604, the third pulley 604 is also connected with the second...

Embodiment 3

[0096] A lawn mower, including a frame system, a walking system, a power system, an operating system 900 , an electrical control system 200 and a header system 400 .

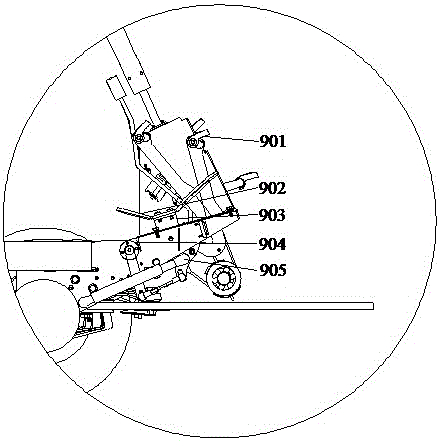

[0097] The control process of the above lawn mower is as follows: the electrical control system 200 receives the control command signal, judges the working state of the whole machine, and realizes the operation of each mode of the whole machine by operating the brake pedal 901, the accelerator pedal 902 and the cutter control switch. control.

[0098] The control modes of the lawn mower include: a vehicle power-on control mode, a vehicle driving control mode, a cutter start control mode and a cutter stop control mode.

[0099] In the vehicle power-on control mode, the vehicle can be powered on only when the parking state and the cutter switch off state are valid at the same time, including the following steps:

[0100] a. The whole machine is in the parking state;

[0101] b. The cutter control switch is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com