Non-chemical distiller's yeast pest control method and three-stage distiller's yeast storage method based on non-chemical distiller's yeast pest control method

A pest control, non-chemical technology, applied in the field of wine making, can solve the problems of expanding economic losses, reducing the efficacy of distiller's yeast, food loss, etc., and achieve the effects of improving production efficiency, reducing liquor loss, and improving storage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

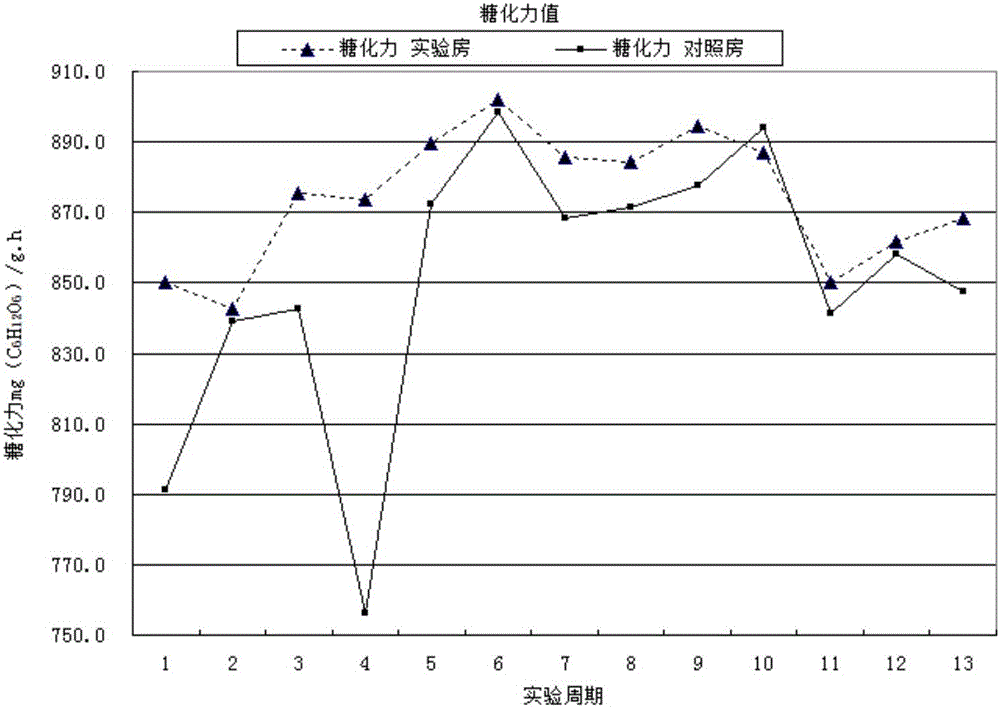

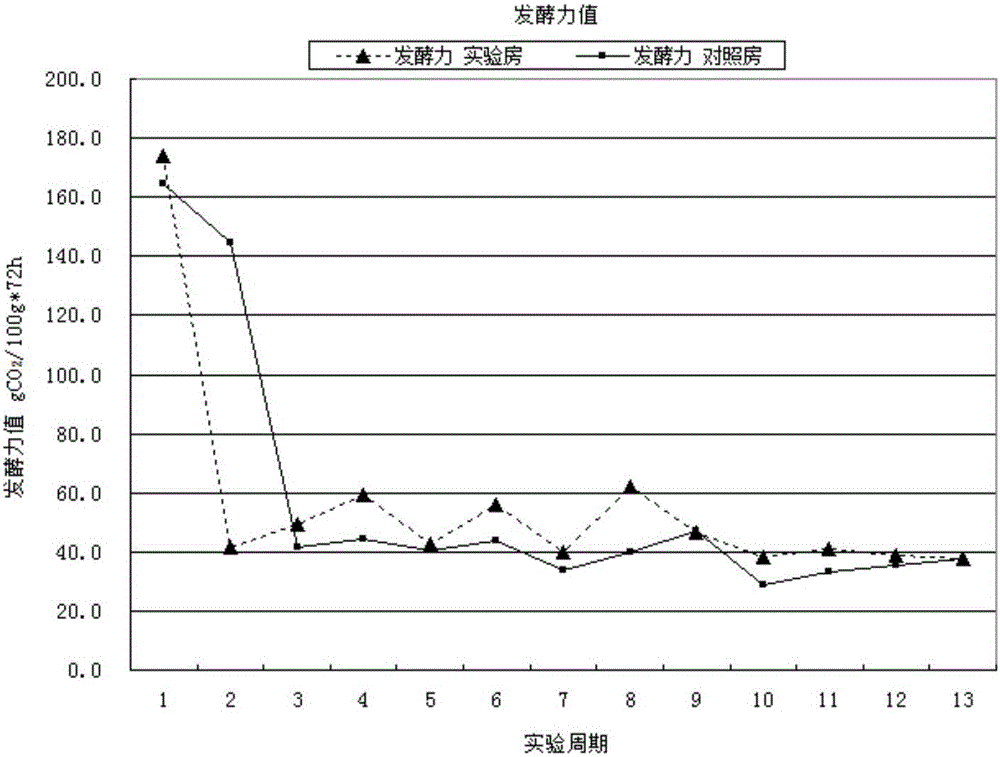

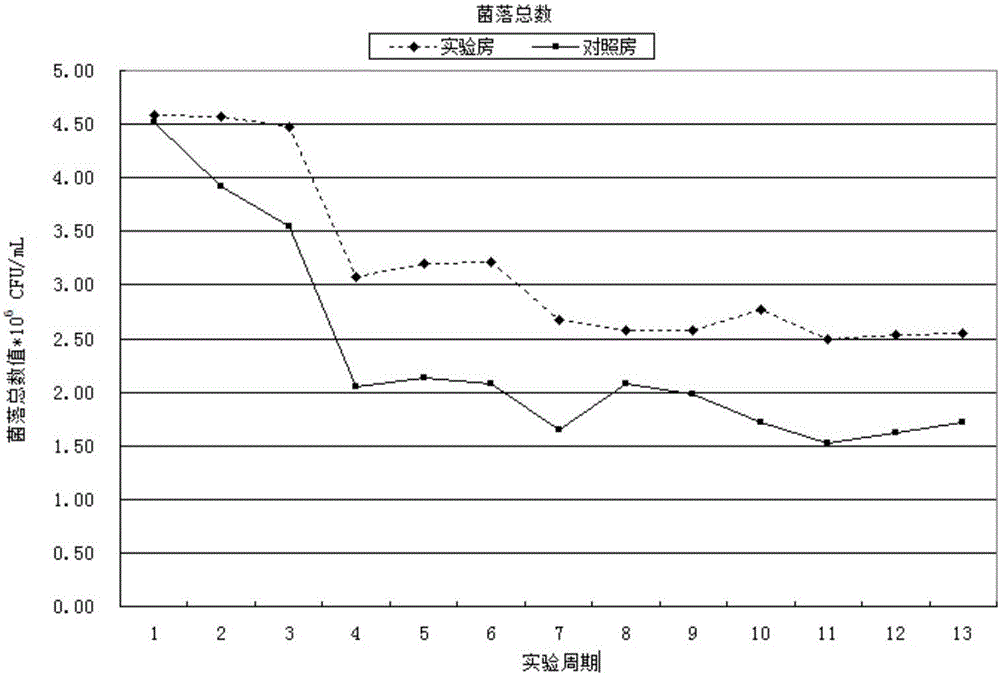

[0047] Two distiller's yeast warehouses with better sealing conditions were set up, one of which was treated with low-concentration carbon dioxide and sprayed with Beauveria bassiana, and was set as the experimental room; the other was not treated in any way, and was set as the control room.

[0048] The koji blocks that have been fermented in the koji workshop and ready to be put into storage are neatly stacked in the two koji warehouses, and three koji stacks (400cm×135cm) are set up in each warehouse, with about 1,500 koji pieces in each koji stack. And there is a distance of 80cm between the curved pile and the wall.

[0049] In order to achieve an obvious contrast effect in a short period of time, and to prevent the interference of exogenous koji pests on the experimental effect, the experiment was carried out under the following conditions:

[0050] 1. Close the doors and windows of the distiller's yeast warehouse, so that the aspergillus in the two warehouses is produce...

Embodiment 2

[0060] Taking the warehouse-style distiller's yeast warehouse actually used by the enterprise as the experimental site, stack two such as Figure 14 The quasi-cube stack shown. One of them is the experimental song duo, and the other is the control song duo. The experimental quilts were completely covered with diatomaceous earth mulch, while the control quilts were left without any treatment. Other spaces in the warehouse are normally stacked with distiller's yeast.

[0061] The changes in the adult density of Quduo koji pests were observed three times a week. The observation points are one point on the bottom layer and one point on the middle layer on each side except the walls, a total of six observation points. The density of koji pest adults and the degree of koji etching are used to reflect the control effect of koji pests. The experimental period is from the end of August to the end of November.

[0062] Nearly a month after the experiment, a large number of corpses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com