High-efficient purifying device for flue gas of coal-fired power plant and use method thereof

An air purification device and technology of purification device, which are applied in chemical instruments and methods, separation methods, electrostatic effect separation, etc., can solve the problem of low purification rate of equipment, and achieve the effect of shortening time, improving purification degree and improving purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the technical problems, technical solutions and advantages to be solved by the invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

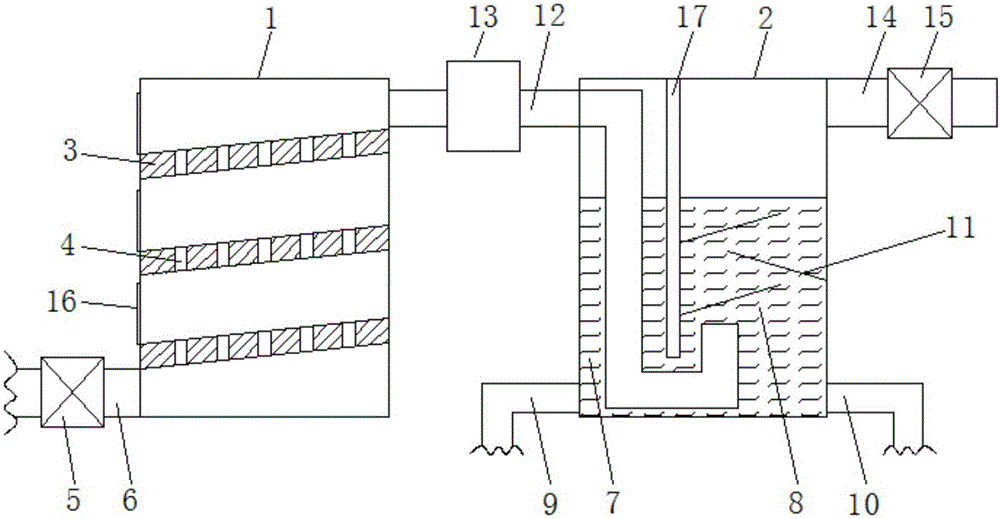

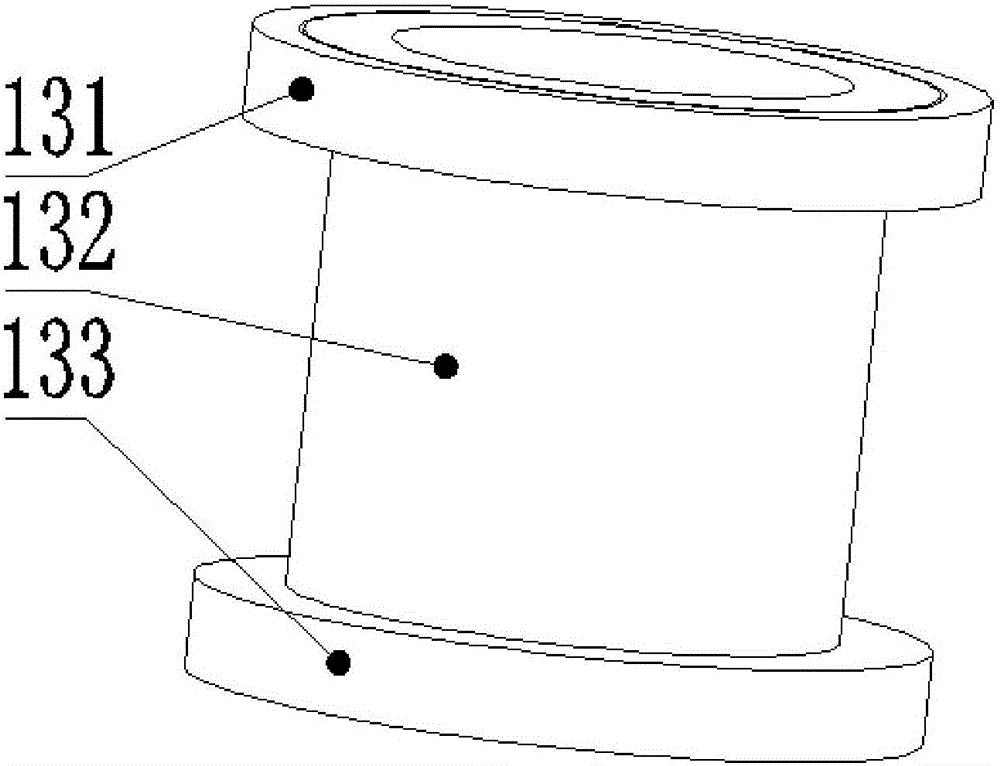

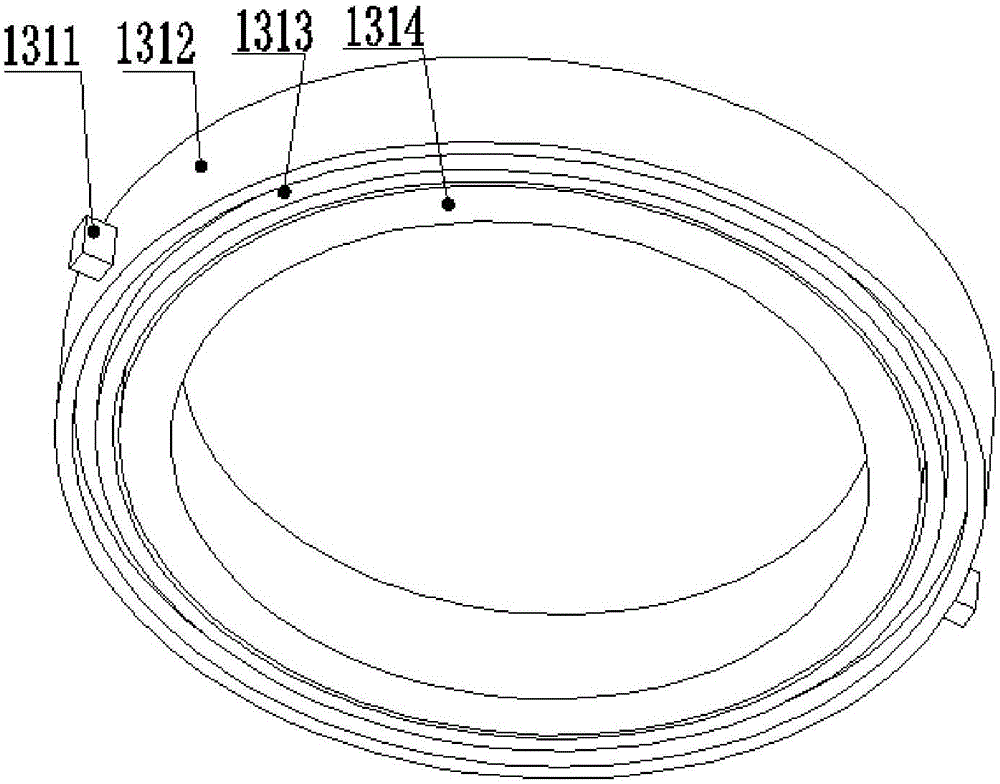

[0058] see Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a high-efficiency purification device for flue gas in a coal-fired power plant, comprising a first purification box 1 and a second purification box 2, the interior of the first purification box 1 is filled with quicklime solids, and the quicklime solids can Reacting with high-temperature flue gas can initially purify the flue gas, and the high temperature speeds up the purification efficiency; one side of the second purification box 2 is provided with a water inlet pipe 9, and when the limestone slurry inside the second purification box 2 is insufficient, it can be Replenish through the water inlet pipe 9, which facilitates the purification; the other side of the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com