Patents

Literature

42results about How to "Purify completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

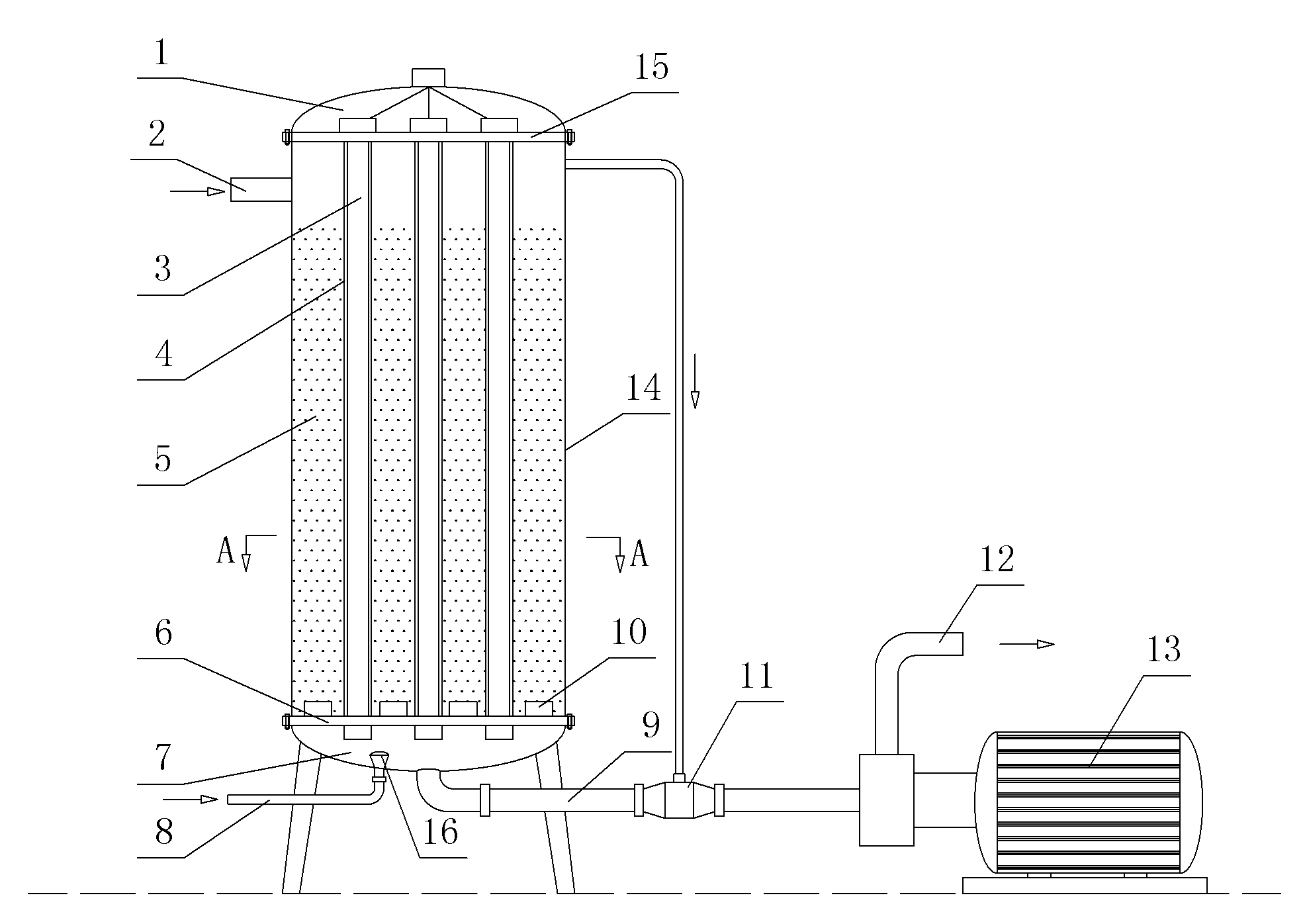

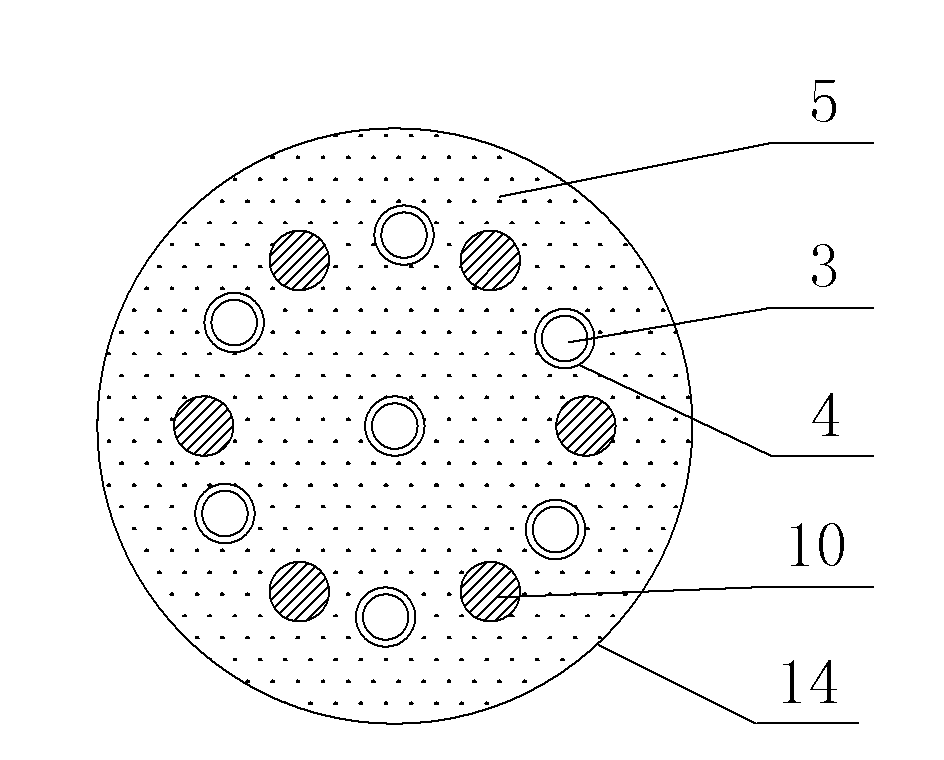

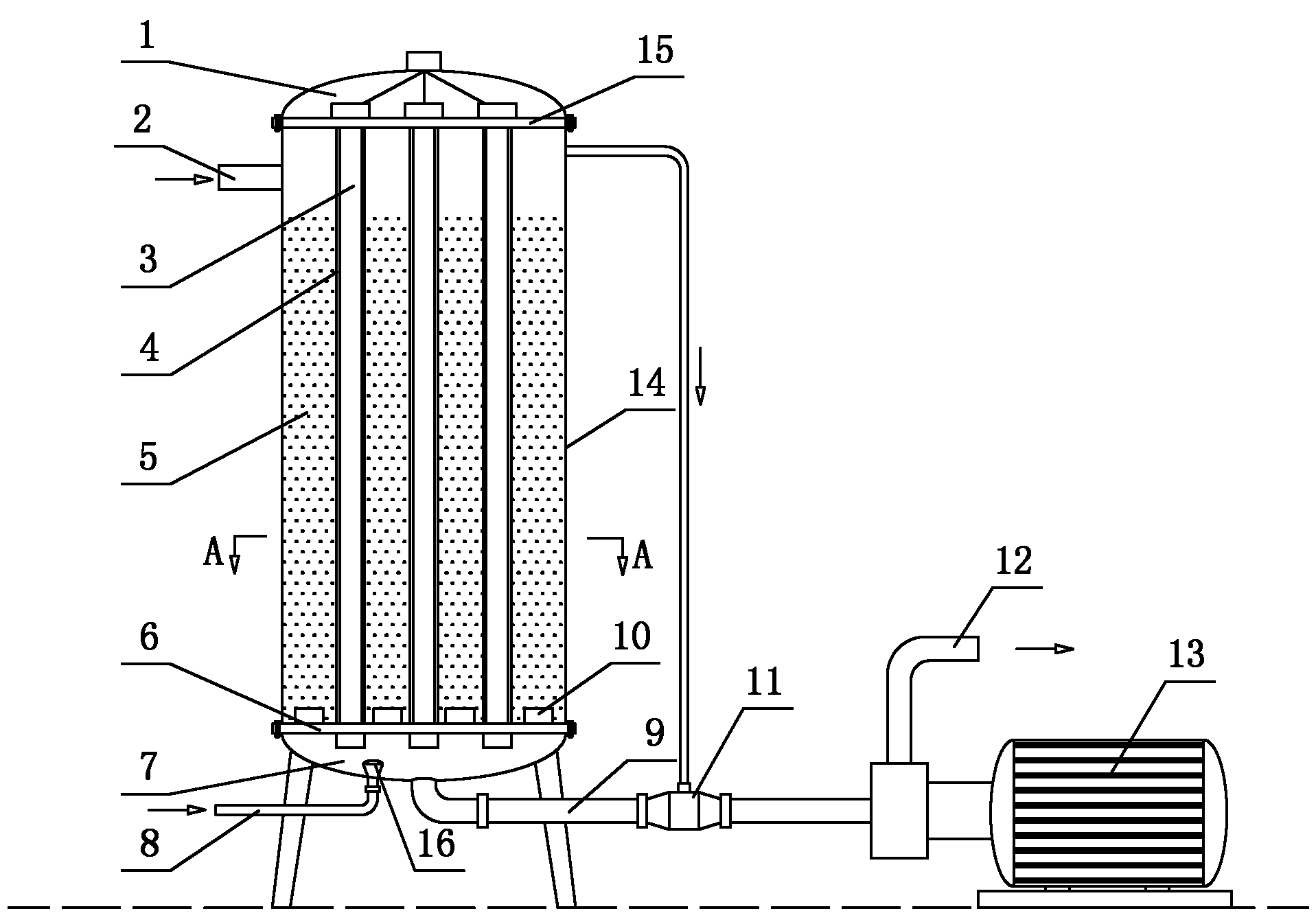

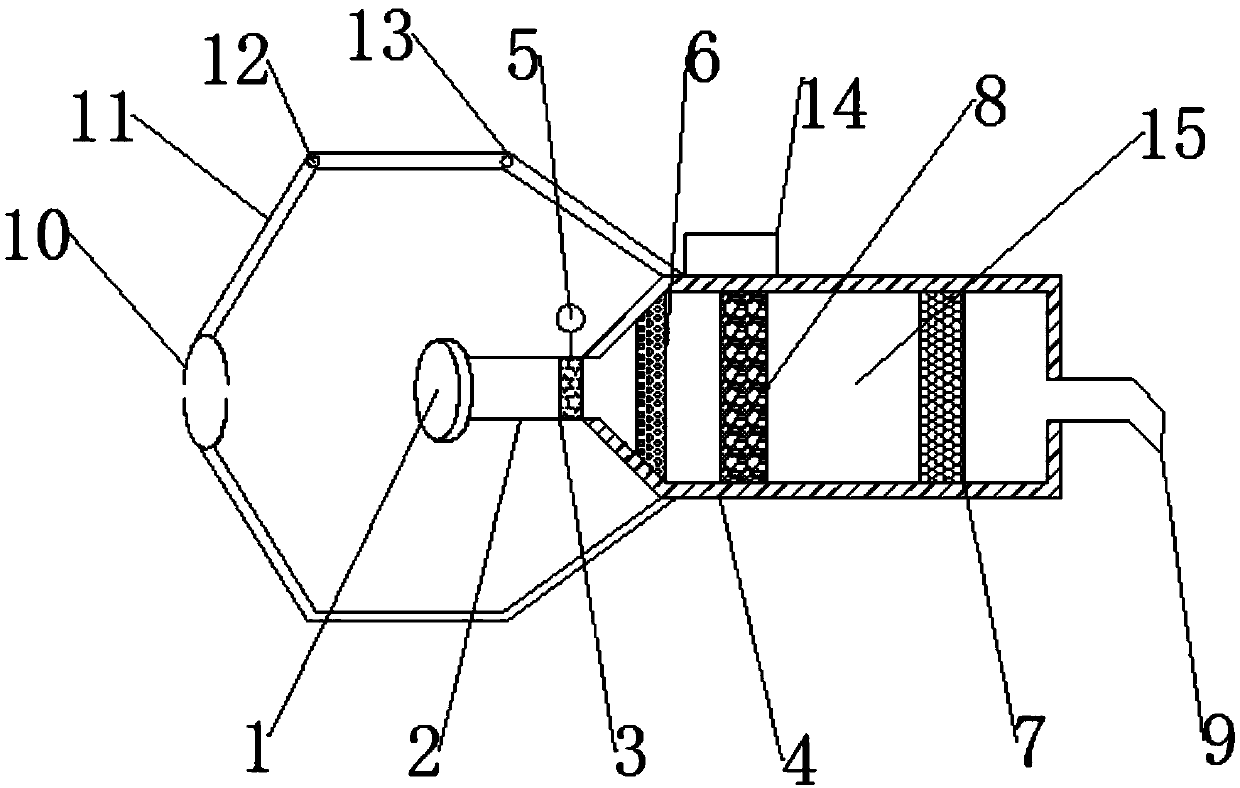

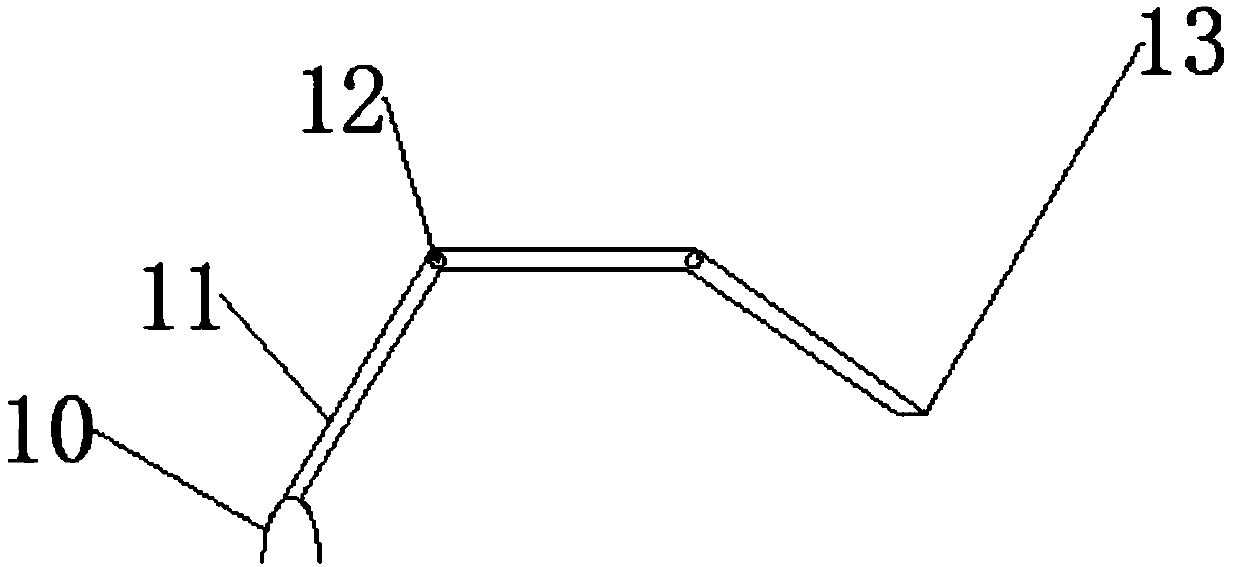

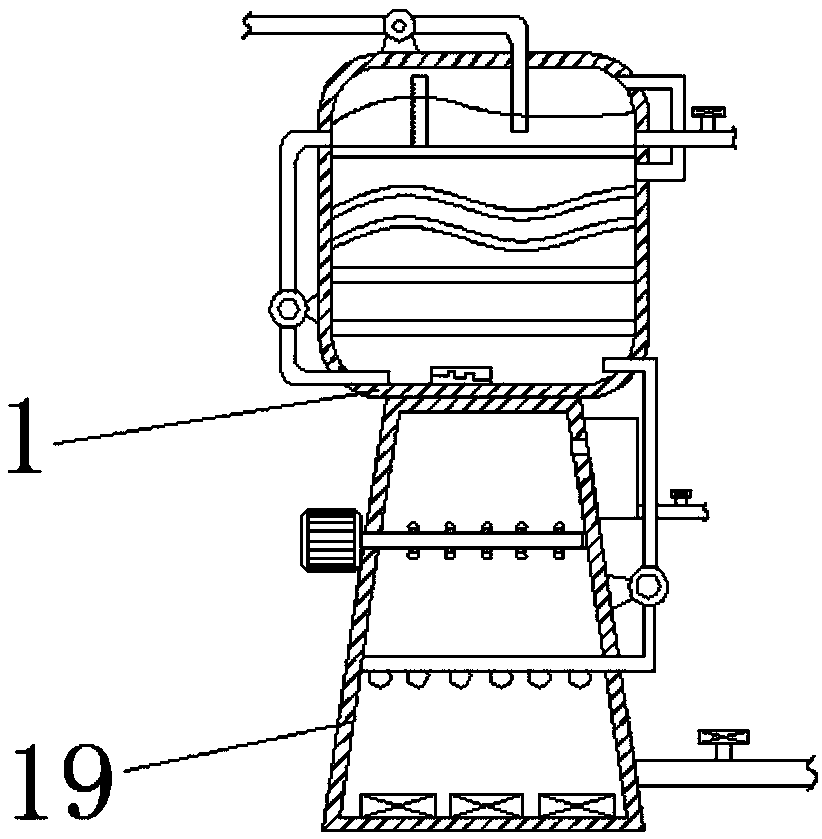

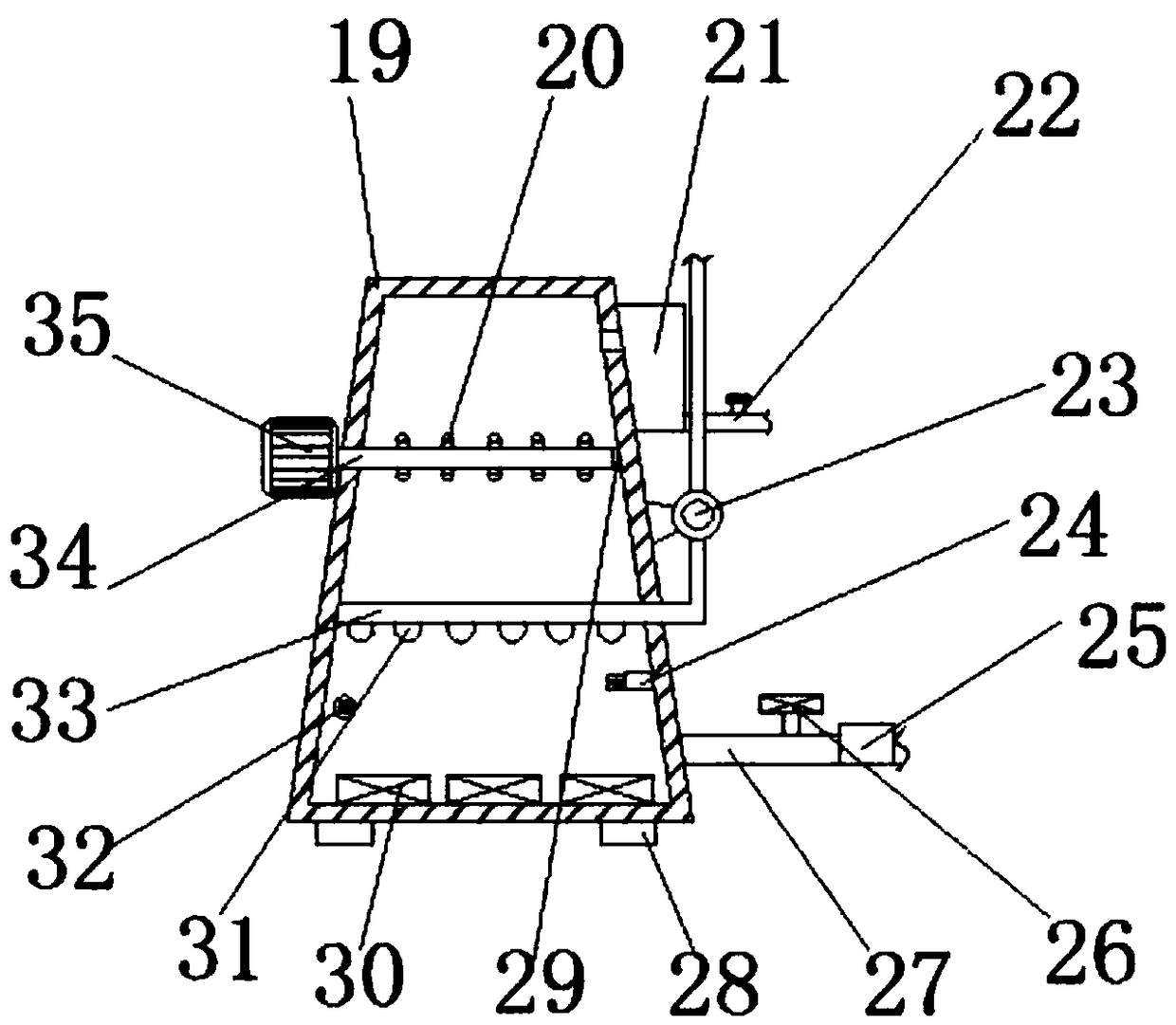

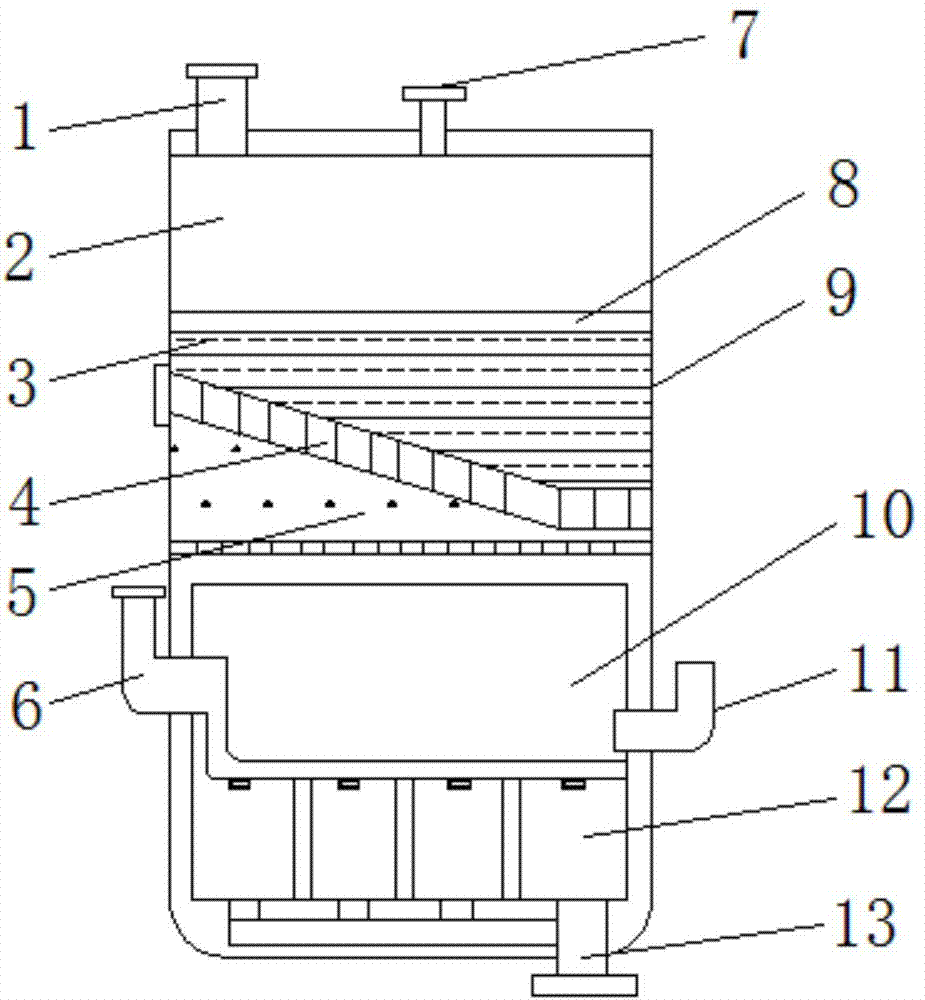

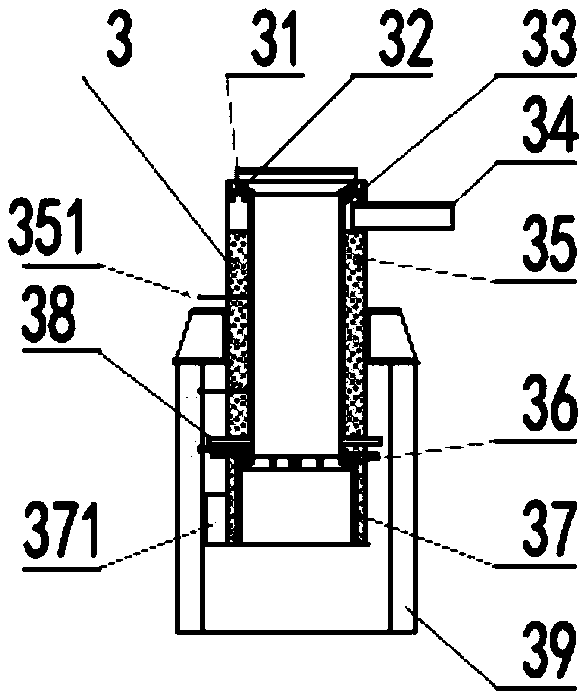

Method and device for purifying vinosity

InactiveCN101948732AImprove inner qualityReduce flow rateAlcoholic beverage preparationUltraviolet lightsSolid particle

The invention discloses a method for purifying vinosity, comprising an oxidation reduction reaction which is carried out on the surfaces of solid particles attached with TiO2 photochemical catalyst layers under the irradiation of ultraviolet light after the body is mixed with oxygen or ozone. The invention also discloses a device for realizing the method for purifying the vinosity. In the invention, multiple groups of ultraviolet light sources are evenly arranged at each part of a reaction chamber to directly irradiate the body and the surface of the photocatalyst; the ultraviolet light can efficiently decompose unsaturated compounds in the body, such as aldehydes, fusel oil, sulfide and other harmful components under the action of catalyst, eliminates impurities and peculiar smell in thewine, eliminates spicy, stimulated and bran taste of green wine, eliminates the off-flavor of edible alcohol, and deeply promotes the inherent quality of the wine.

Owner:李建东

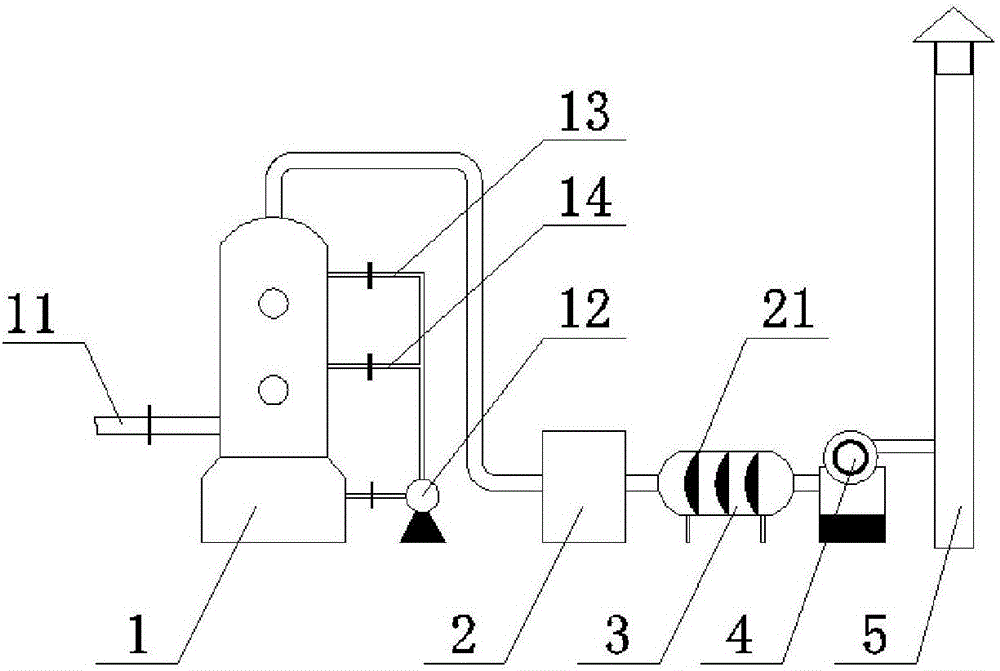

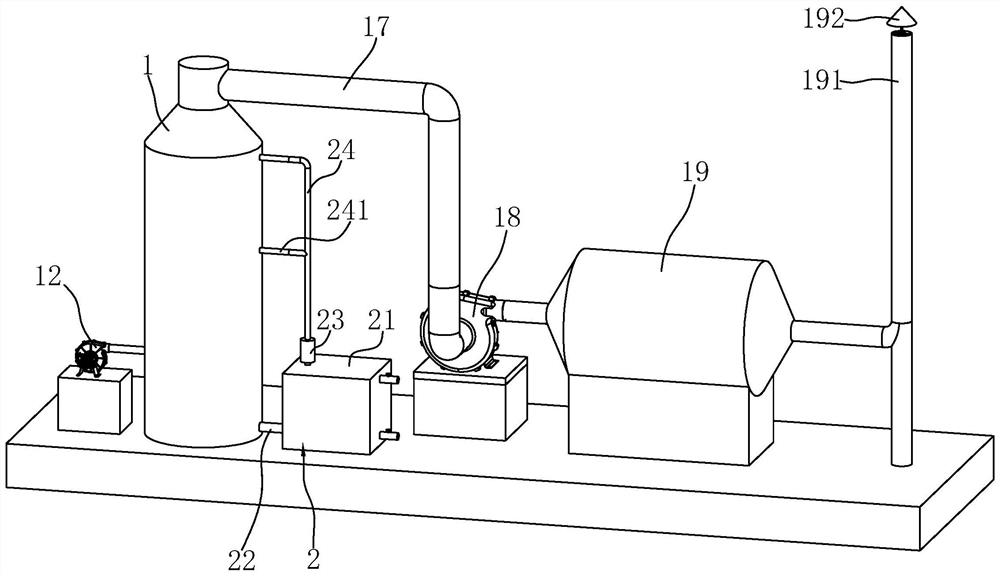

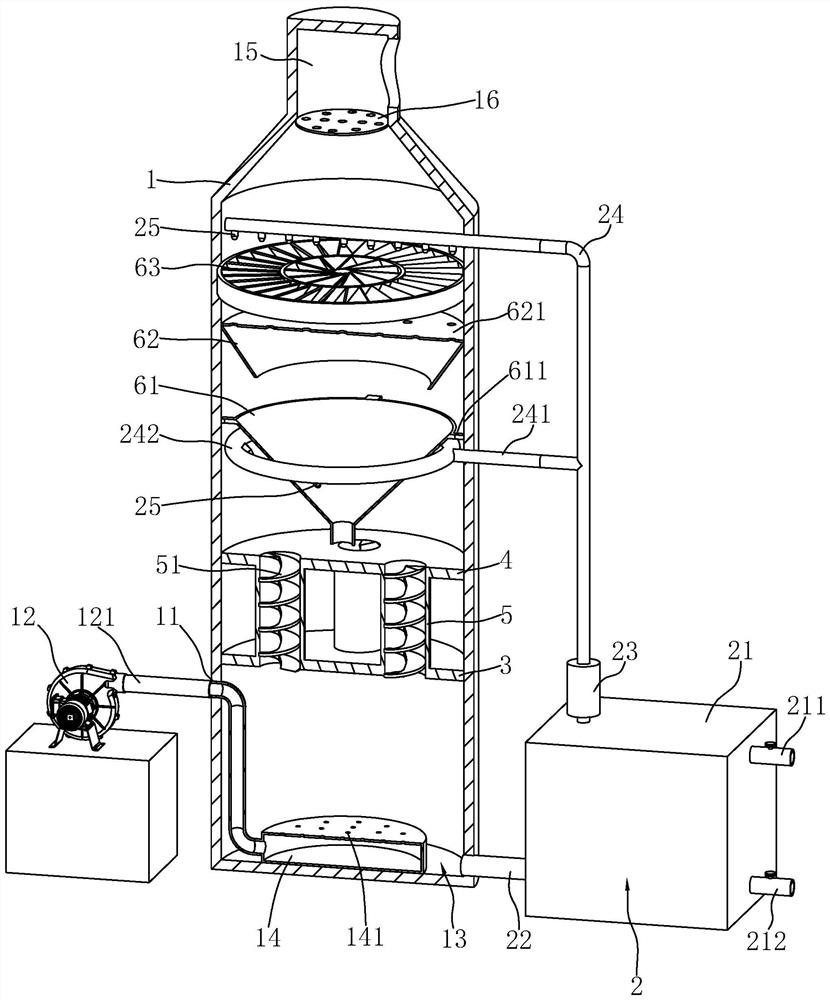

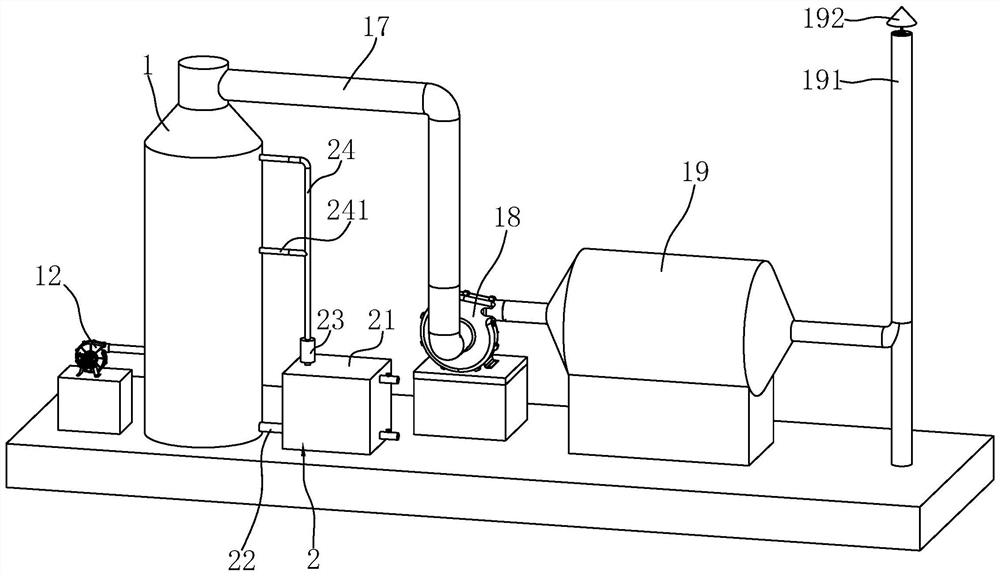

Paint spray room waste gas treating device

PendingCN106731395AAvoid clogging the linesGuaranteed continuous operationCombination devicesSpray towerActivated carbon

The invention relates to a paint spray room waste gas treating device, and belongs to the technical field of waste gas treating. The paint spray room waste gas treating device comprises a spray tower, a demisting device, an activated carbon adsorption device, a fan and a chimney which are connected in sequence by pipelines; paint spray room waste gas enters from a gas inlet of the spray tower, and passes through the spray tower, the demisting device, and the activated carbon adsorption device for purification treatment, and after meeting the standard, the waste gas is discharged from the chimney. The paint spray room waste gas treating device can be used for removing paint mist completely and has a good adsorption purifying effect on the waste gas.

Owner:安徽德玉环境工程装备有限公司

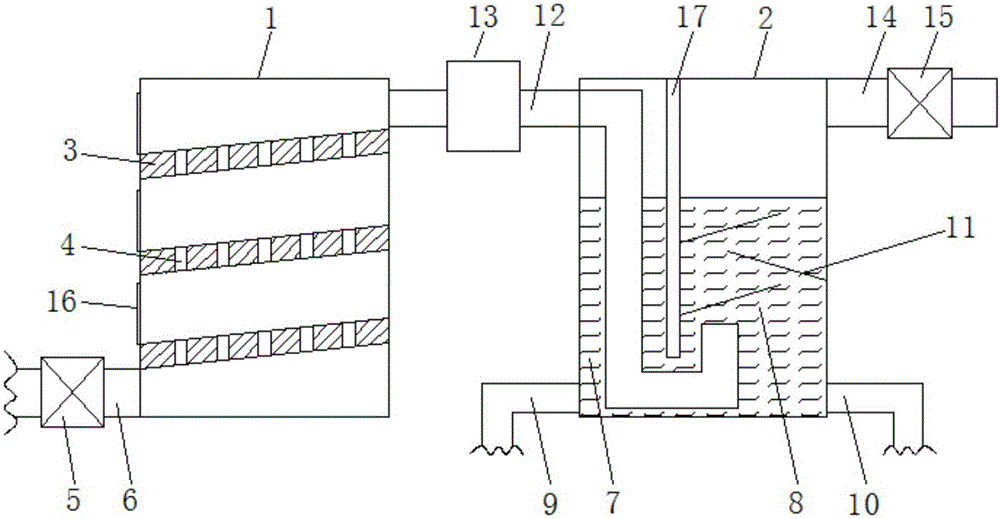

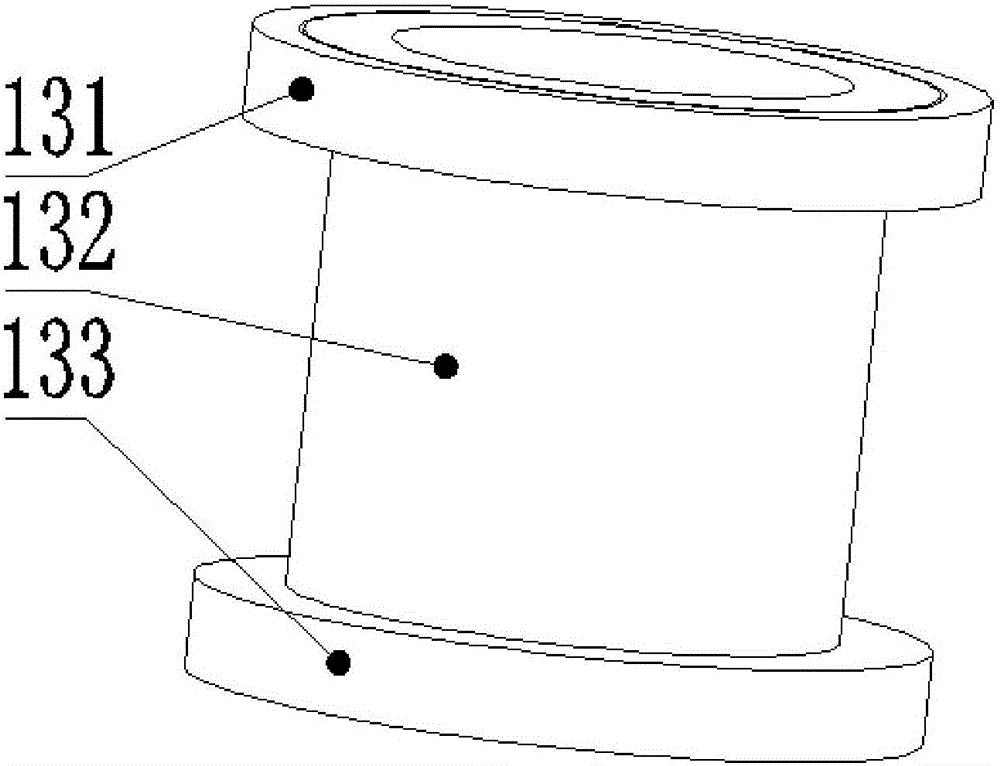

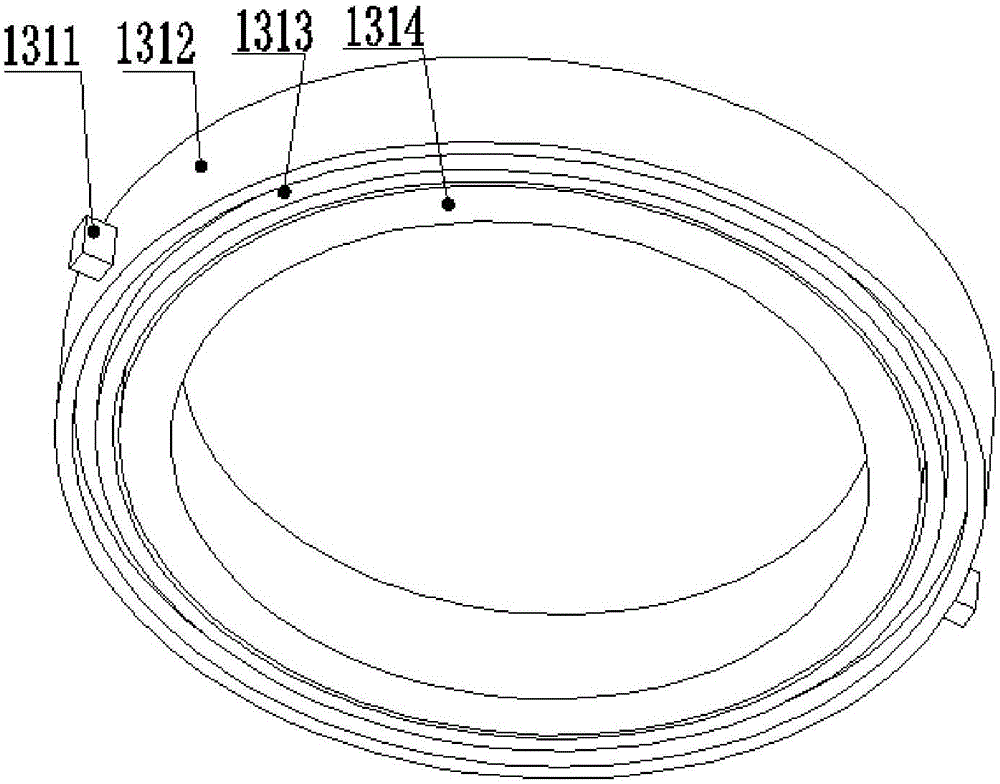

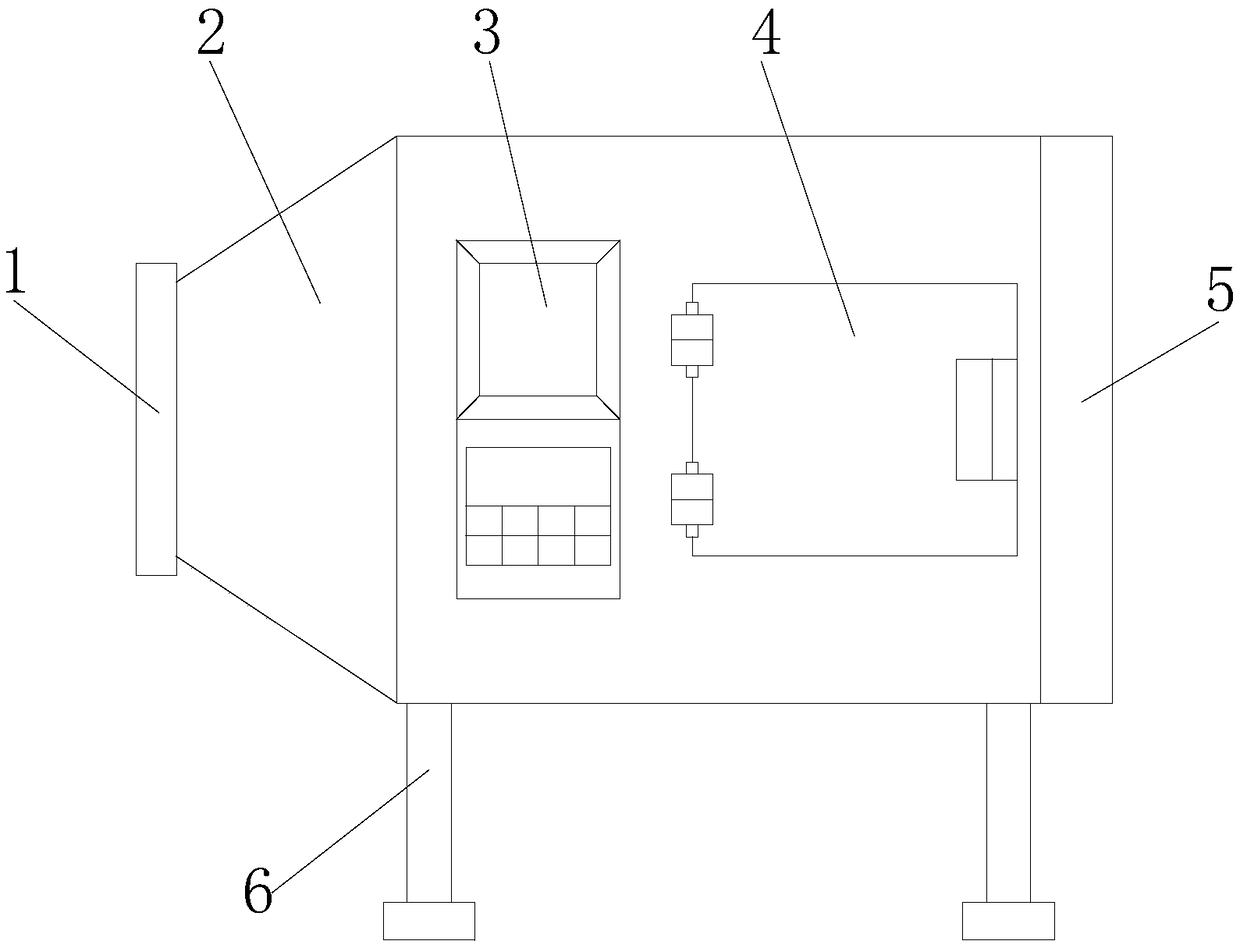

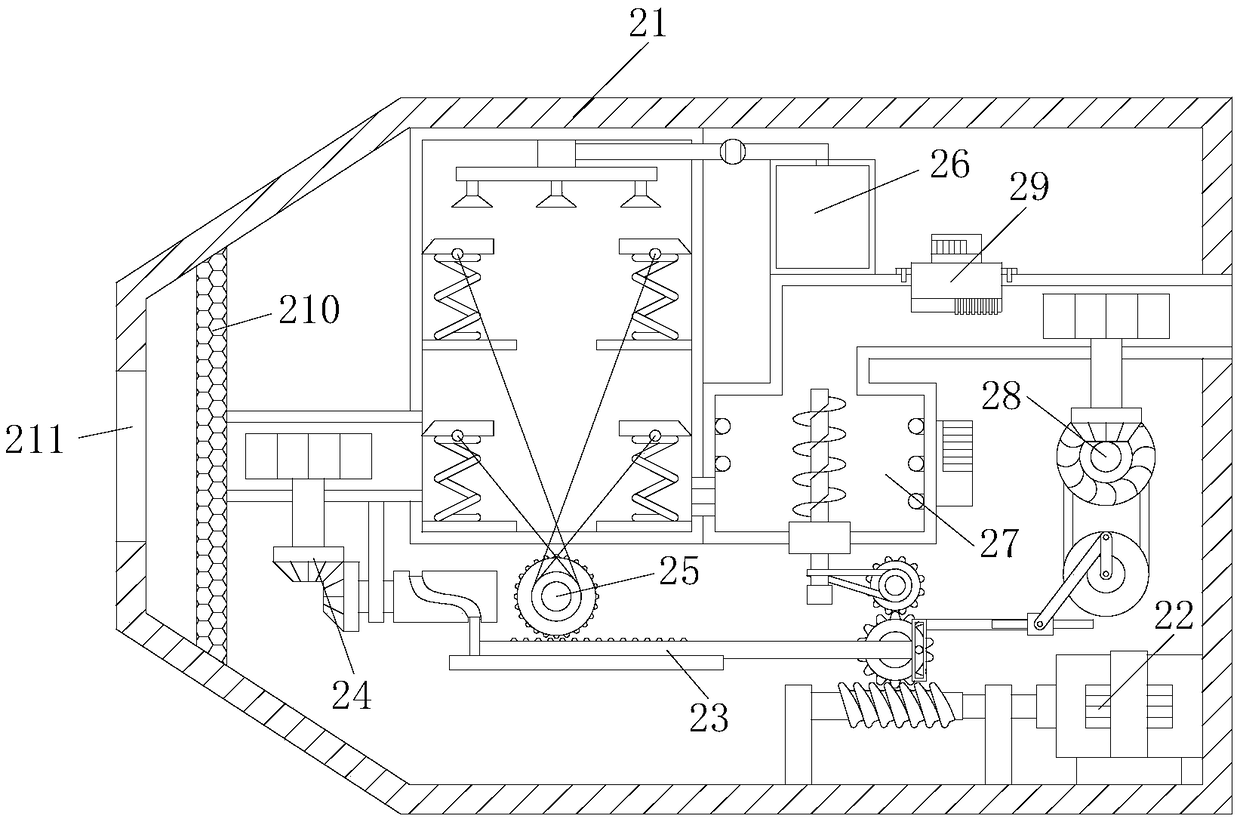

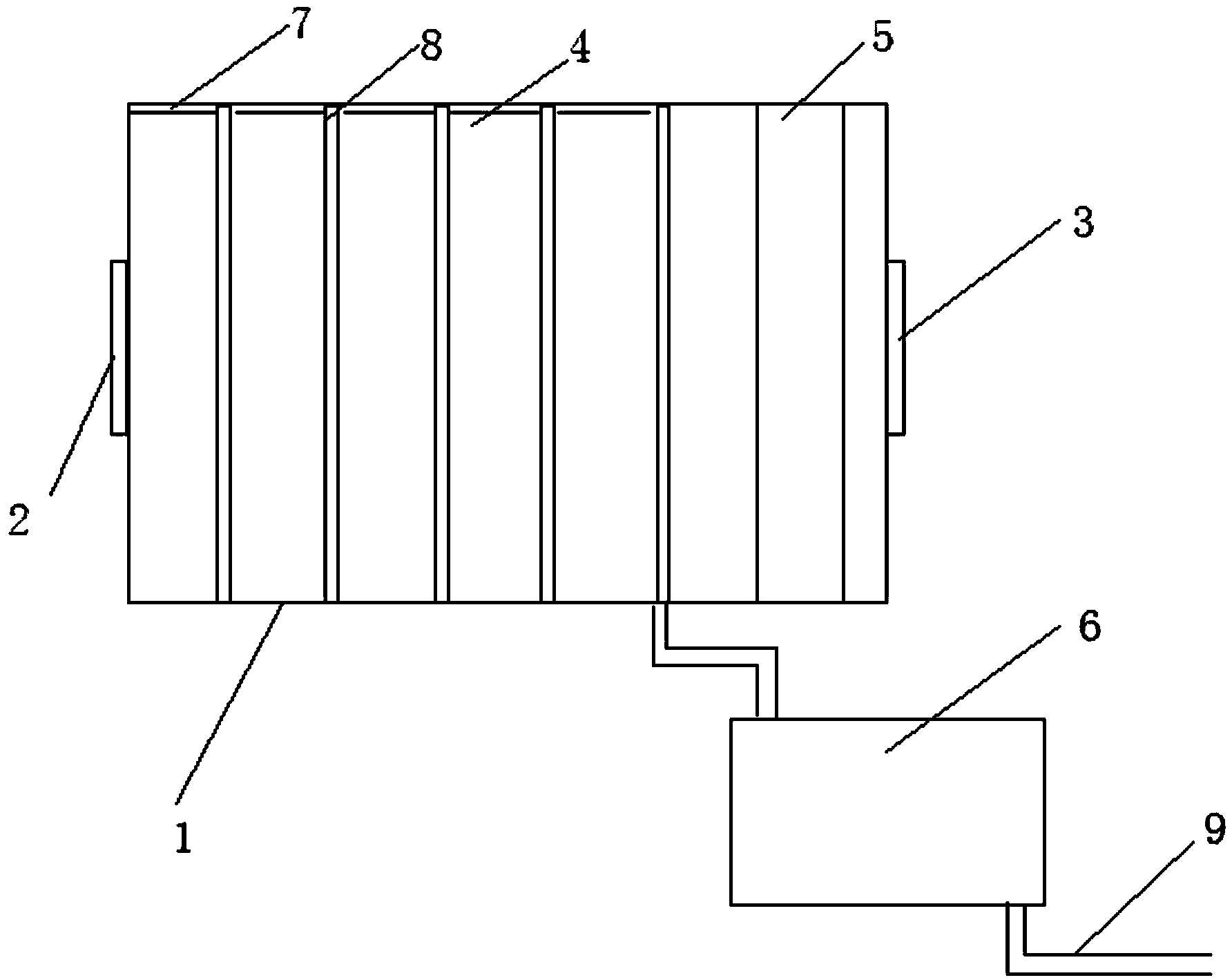

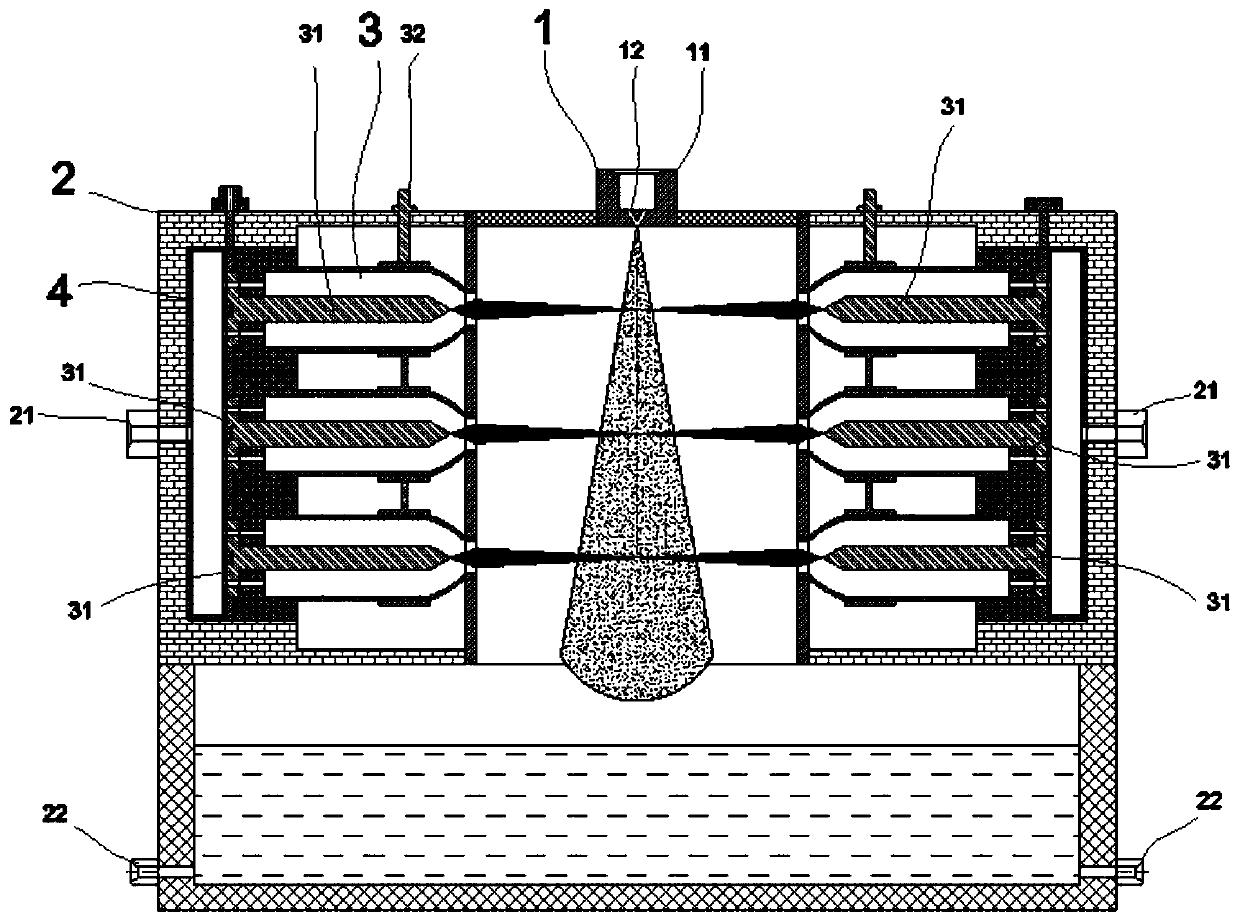

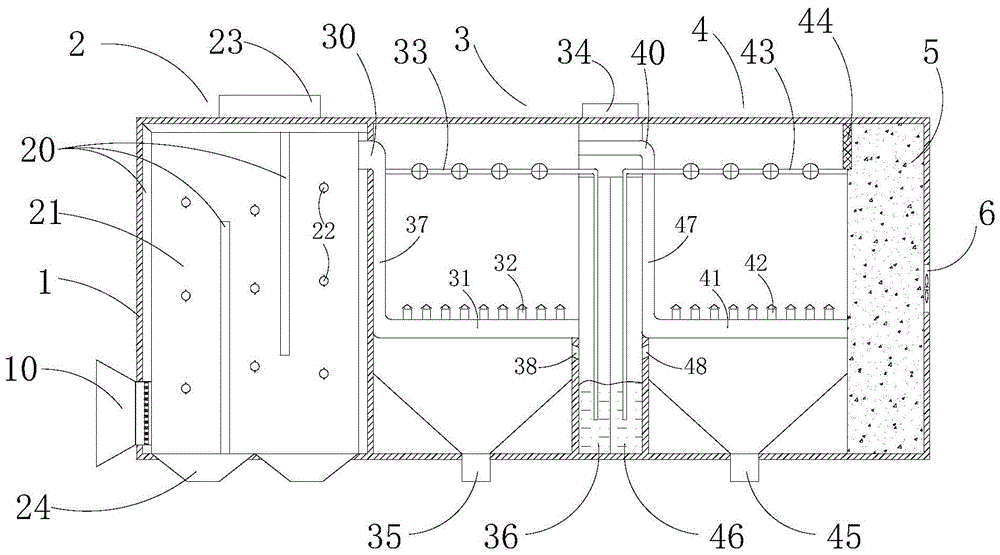

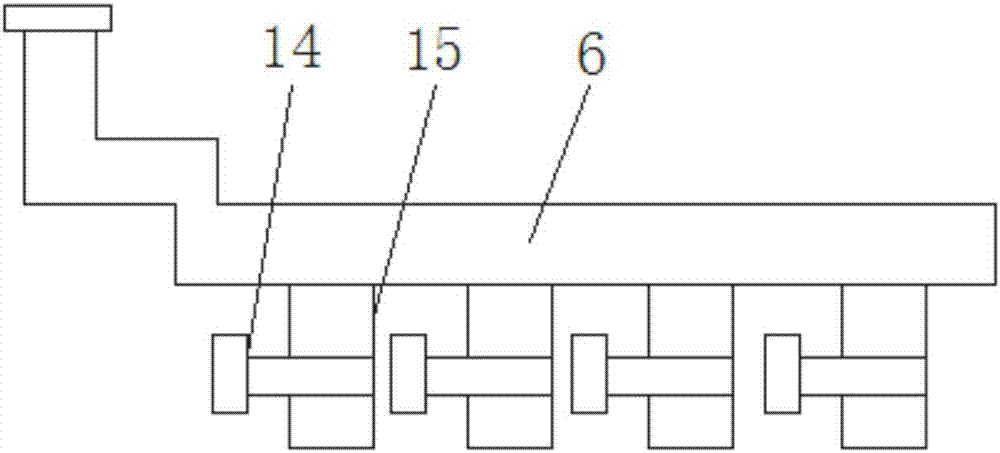

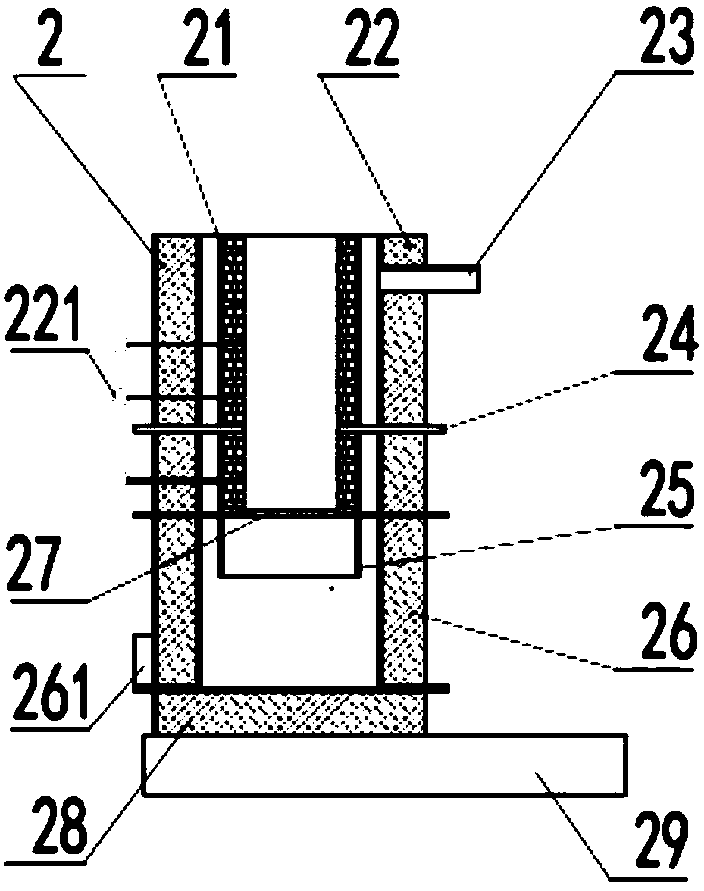

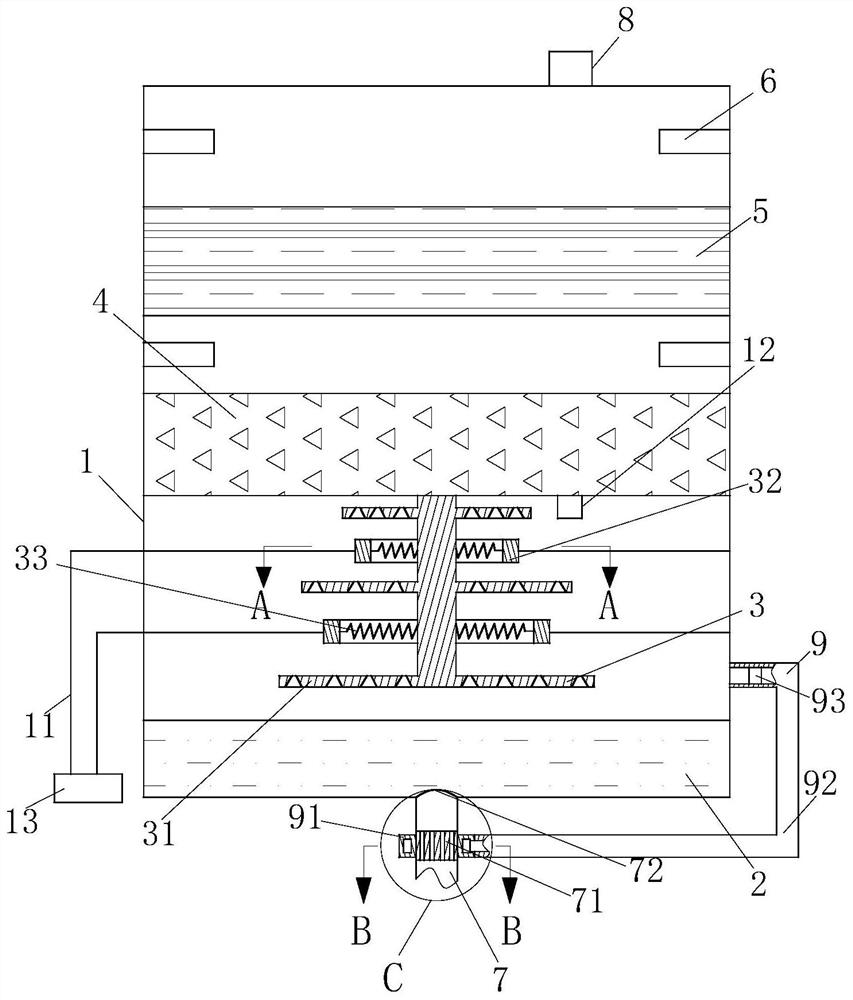

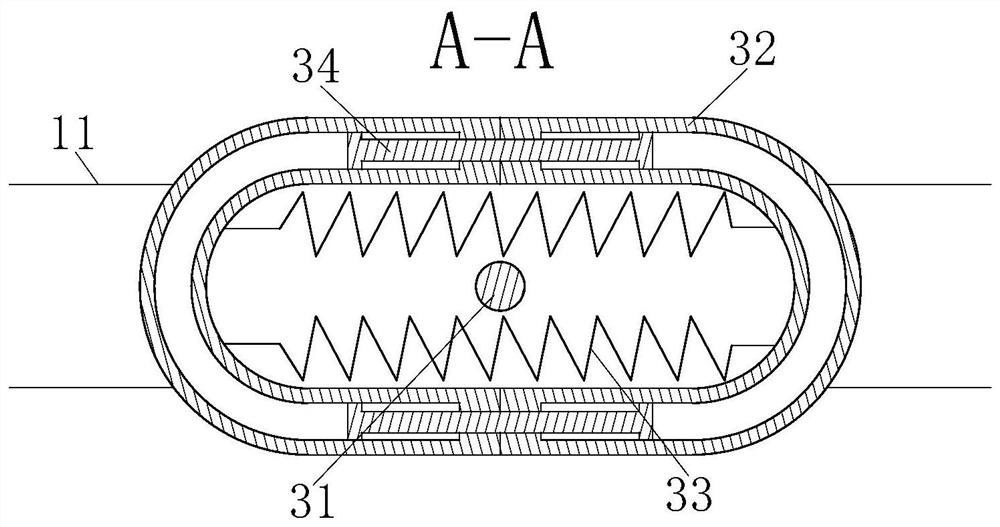

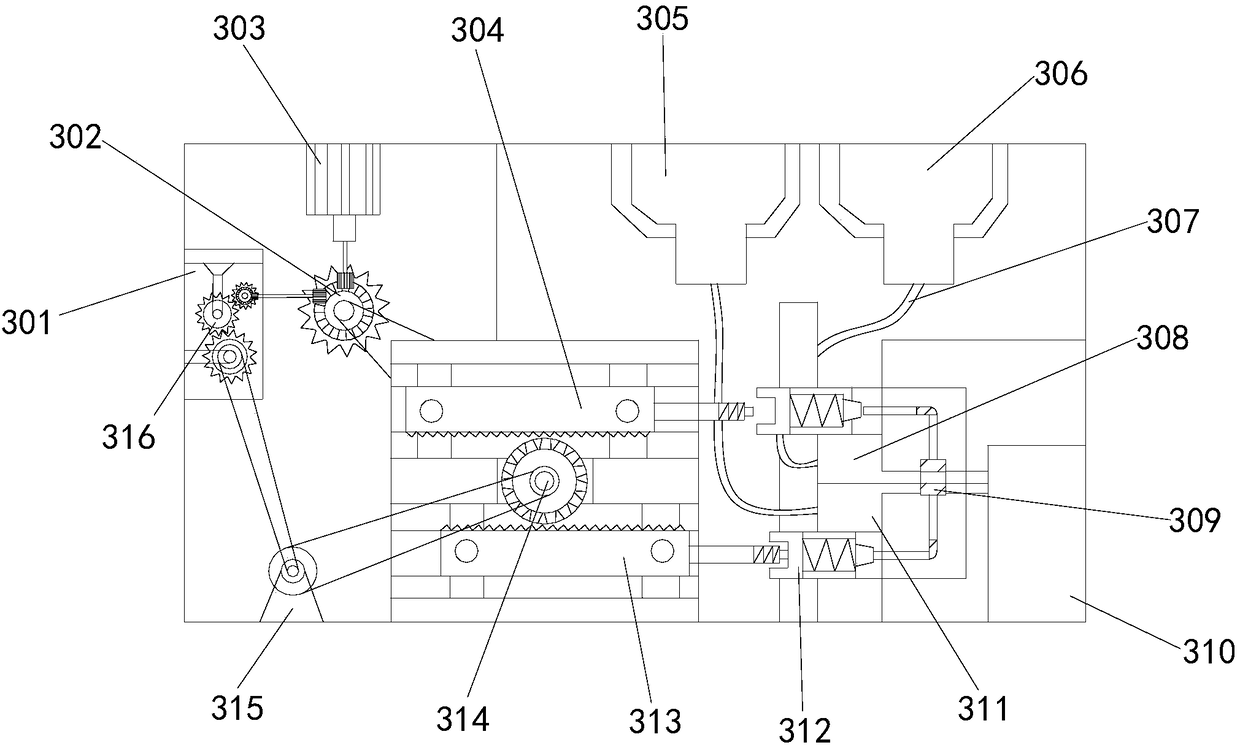

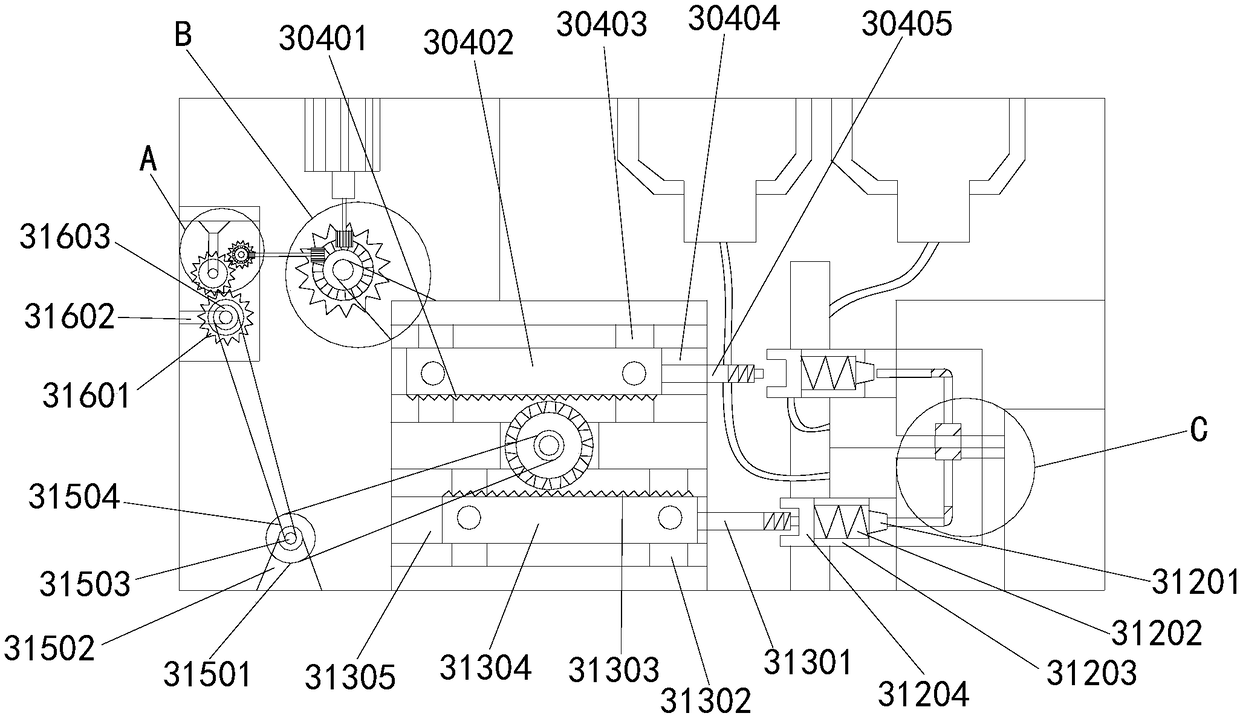

Horizontal circle-flow dust-removal denitration desulphurization apparatus

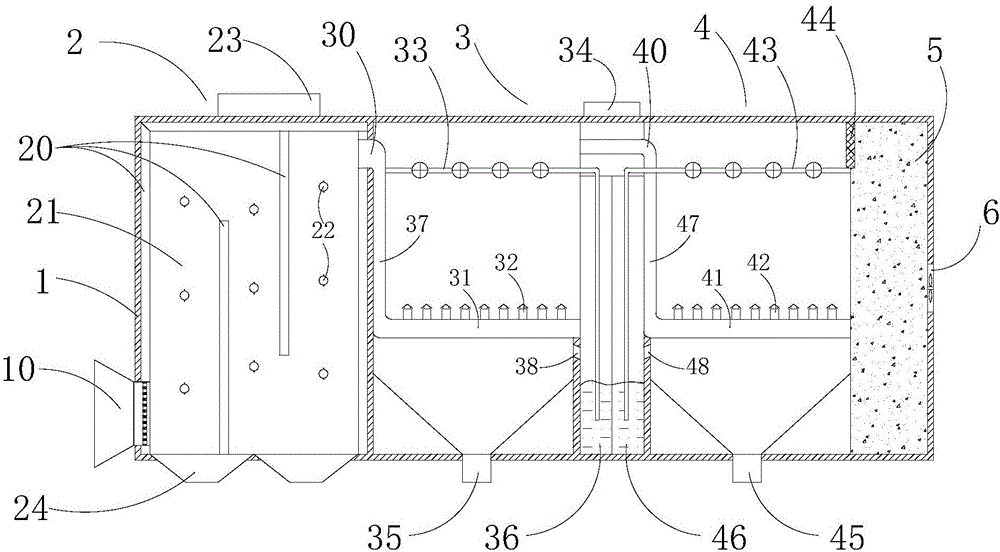

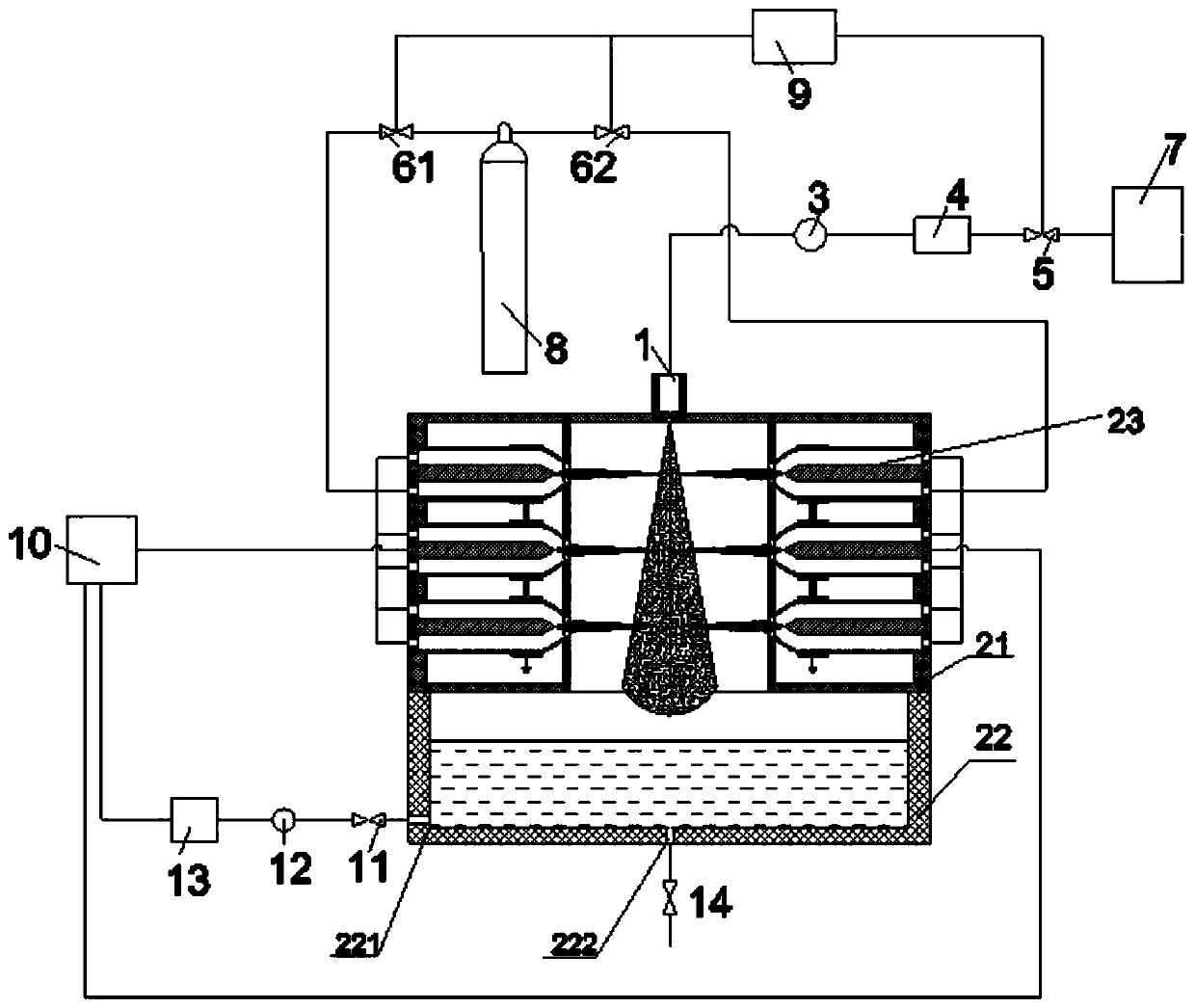

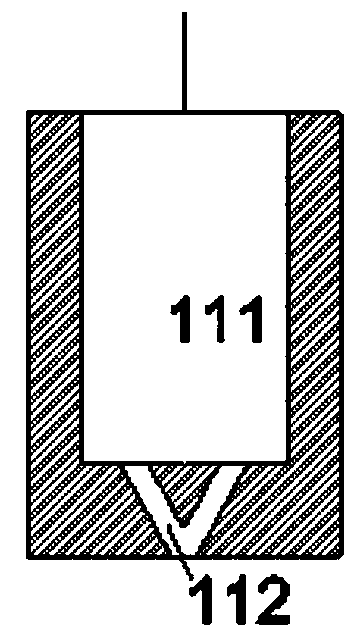

ActiveCN104984653AReasonable structureEasy to disengageDispersed particle separationExternal electric electrostatic seperatorEngineeringLiquid storage

The invention discloses a horizontal circle-flow dust-removal denitration desulphurization apparatus. The horizontal circle-flow dust-removal denitration desulphurization apparatus comprises a shell, a dust removal chamber, a denitration chamber, a desulphurization chamber and a drying chamber, wherein the dust removal chamber, the denitration chamber, the desulphurization chamber and the drying chamber are installed in the shell, an air inlet is formed in the left side of the dust removal chamber, a dust collection polar plate and a cathode filament rod are installed in the dust removal chamber, an electromagnetic vibrator is installed above the dust removal chamber, an ash bucket is installed below the dust removal chamber, the denitration chamber is arranged at the right side of the dust removal chamber, a denitration liquid spraying device is installed above an inner chamber of the denitration chamber, the right side of the denitration chamber is provided with a denitration liquid storage groove, the right side of the denitration liquid storage groove is provided with a desulphurization liquid storage groove, the right side of the desulphurization liquid storage groove is provided with the desulphurization chamber, a desulphurization liquid spraying device is installed above an inner chamber of the desulphurization chamber, the right side of the desulphurization chamber is provided with a drying chamber, and the right side surface of the drying chamber is provided with an exhaust apparatus. The horizontal circle-flow dust-removal denitration desulphurization apparatus is simple in structure, easy to repair and maintain and capable of improving the purifying quality of the air.

Owner:YIXING HAINA ENVIRONMENTAL ENG

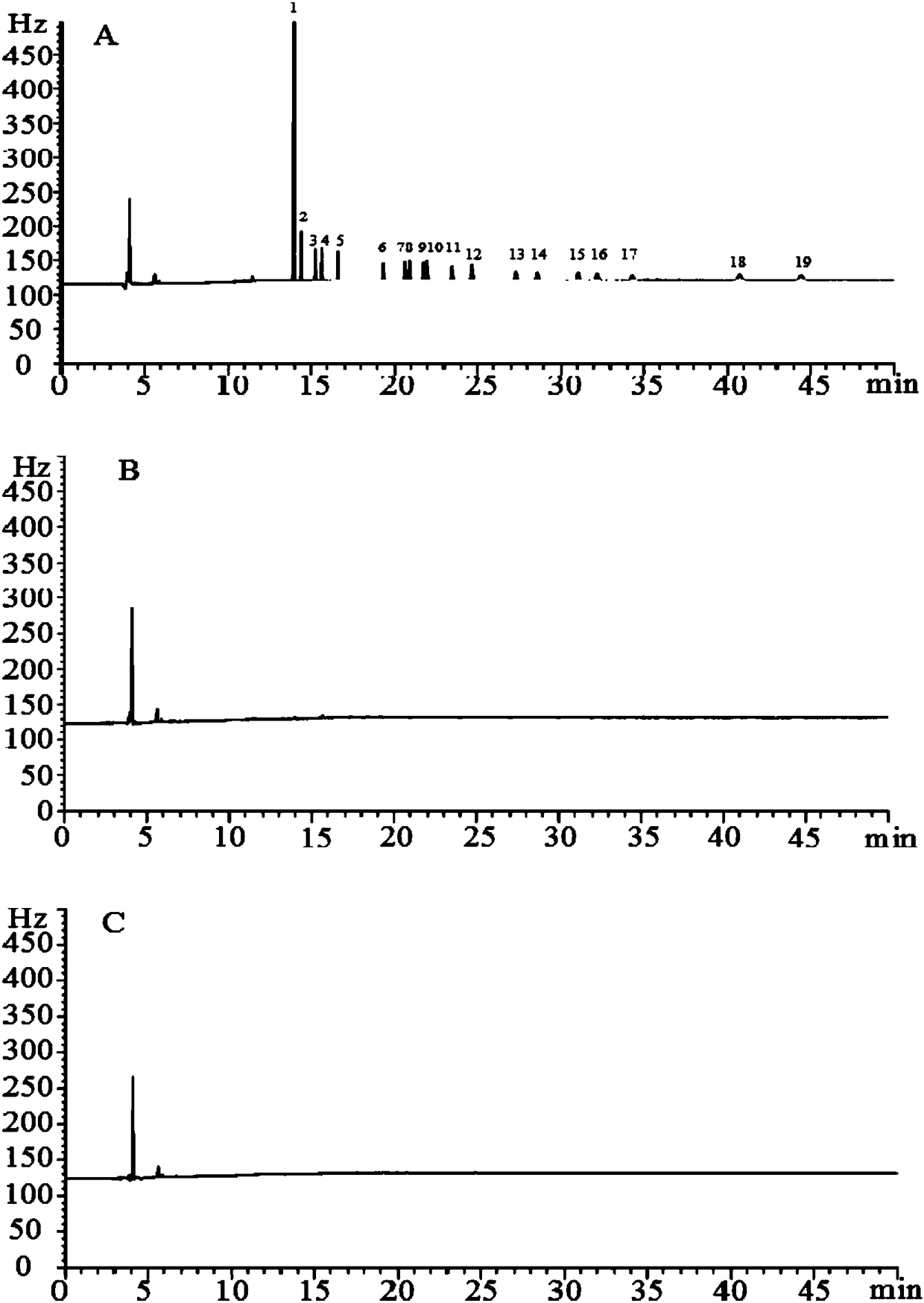

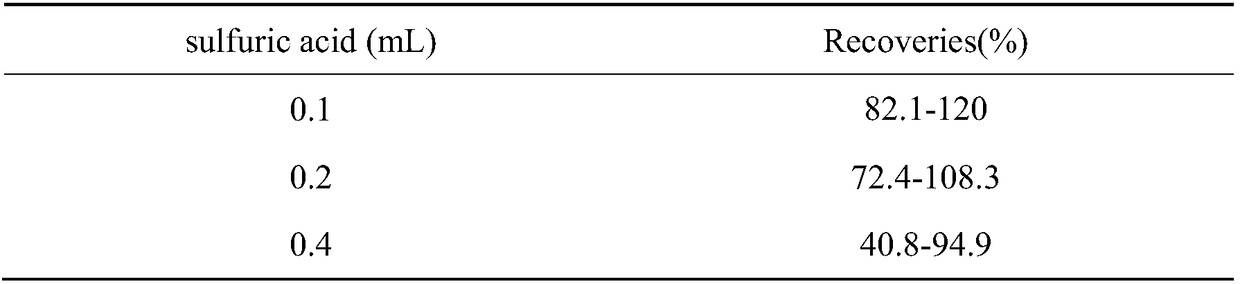

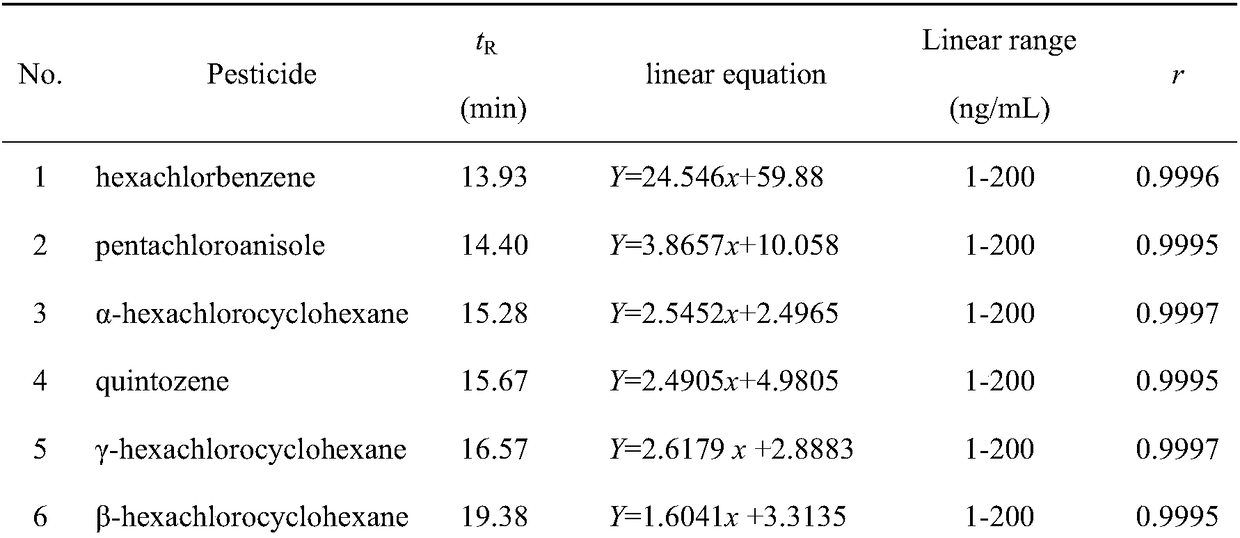

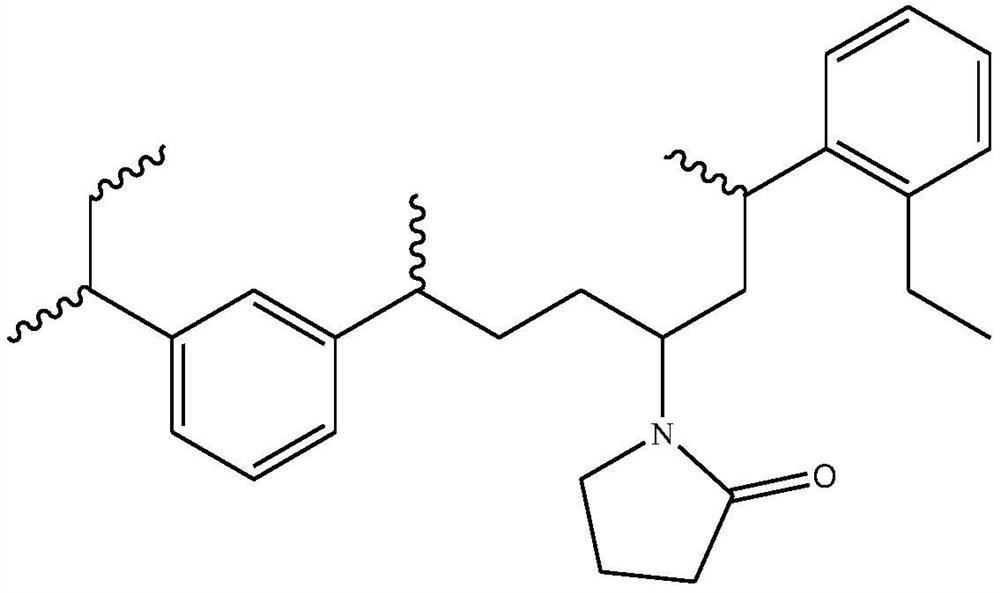

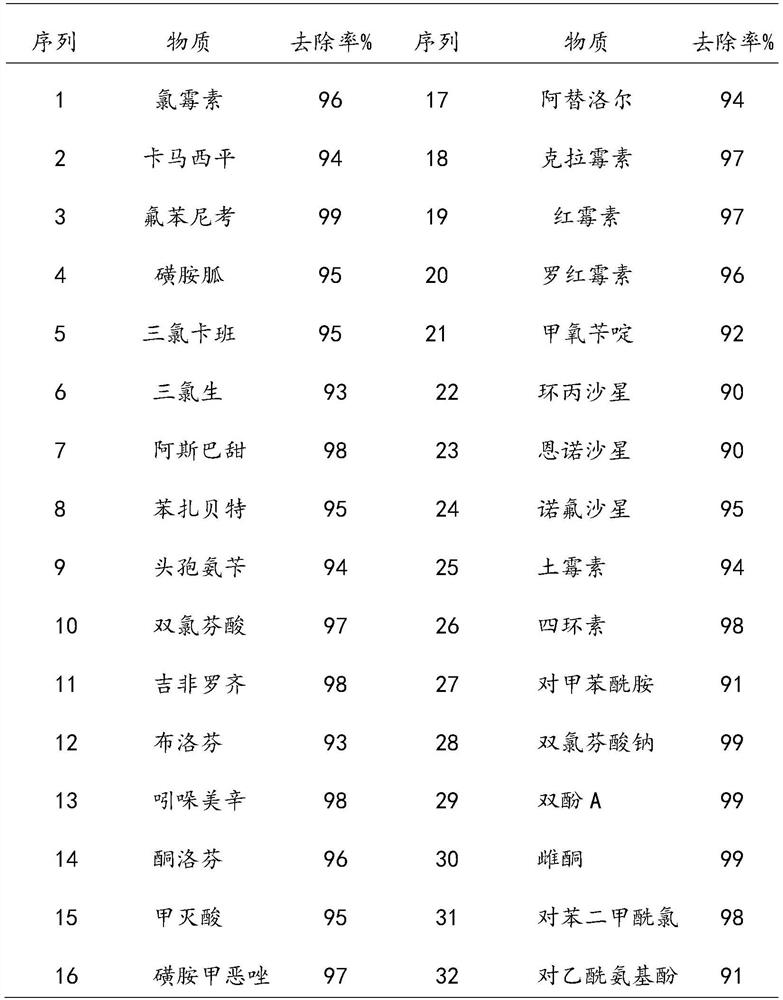

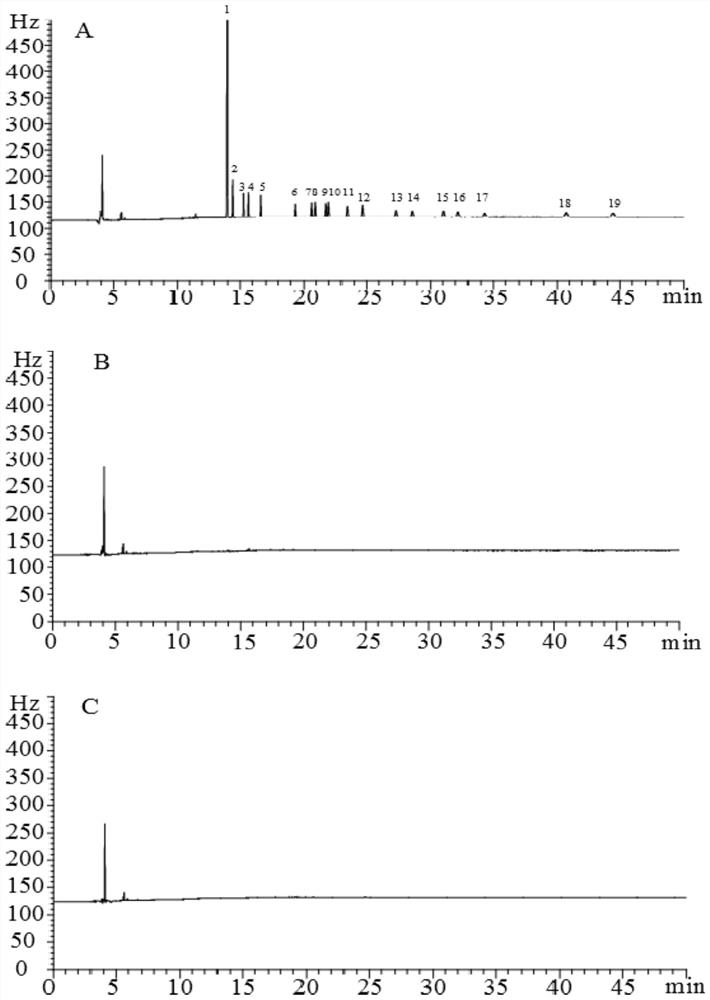

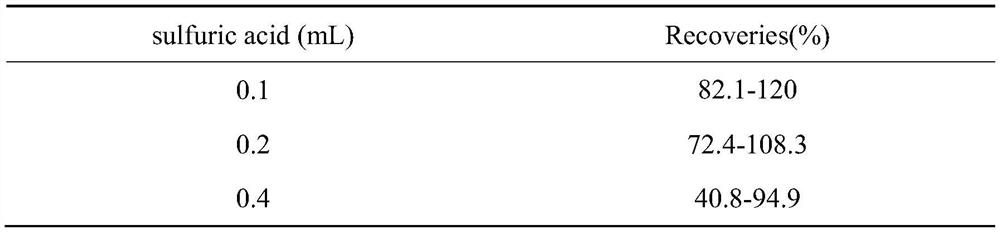

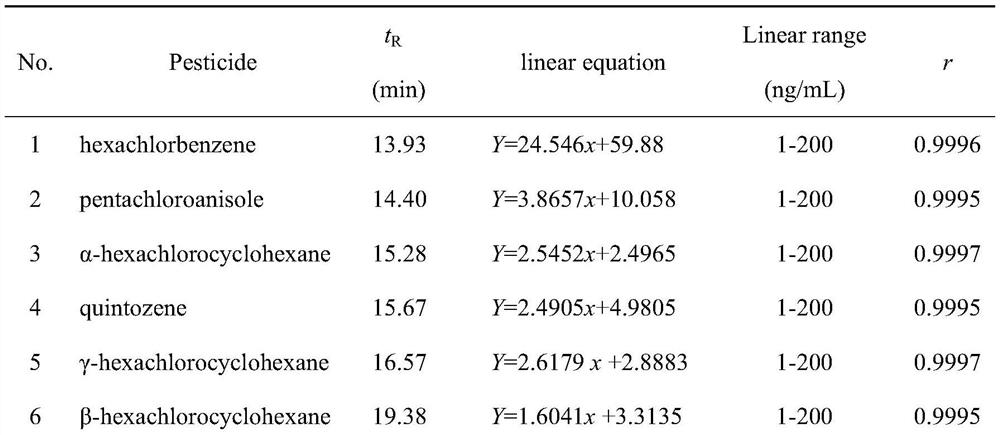

Method for detecting residual amount of 19 organochlorine pesticides in pseudo-ginseng

ActiveCN108061774AReduce usageThe processing method is completelyComponent separationWater bathsPesticide residue

The invention relates to a method for detecting the residual amount of 19 organochlorine pesticides in pseudo-ginseng. The method includes the following steps: (1) preparation of a test sample solution: taking a medicinal material powder, adding petroleum ether, soaking, carrying out suction filtration, carrying out fractionated washing of the residue with petroleum ether, transferring to a round-bottom flask, carrying out water bath rotary steaming at the temperature of 25-45 DEG C to be nearly dry, re-dissolving with n-hexane, adding concentrated sulfuric acid, fully jerking, after completion of the reaction, centrifuging, and taking a supernatant for standby application; (2) preparation of a mixed reference substance solution: taking 19 pesticide standard substances, placing in volumetric flasks, adding n-hexane to dilute to the scale, to obtain reserve liquids of the reference substances, respectively weighing the reserve liquids of the reference substances in a volumetric flask, diluting with n-hexane to the scale, and thus obtaining the mixed reference substance solution; and (3) detecting method: taking the test sample solution and the mixed reference substance solution, injecting into a gas chromatograph, and detecting.

Owner:TIANJIN TASLY PHARMA CO LTD

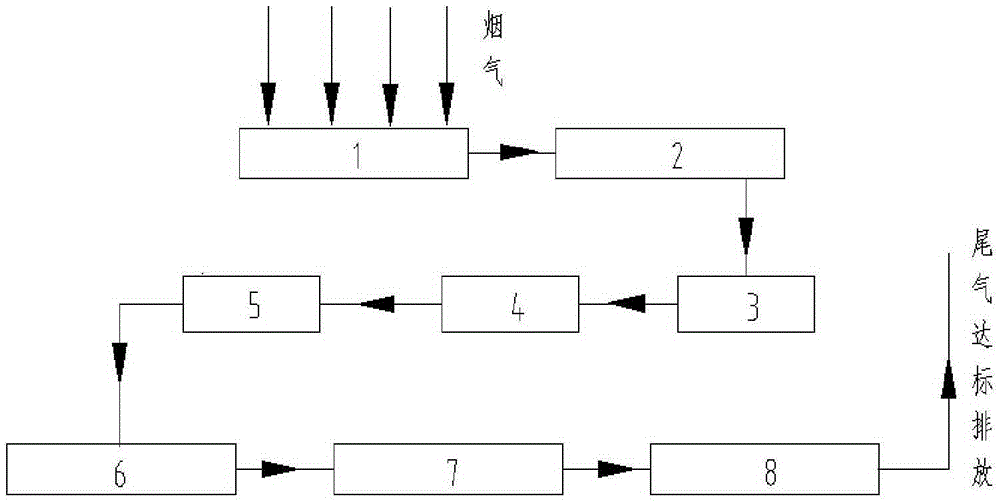

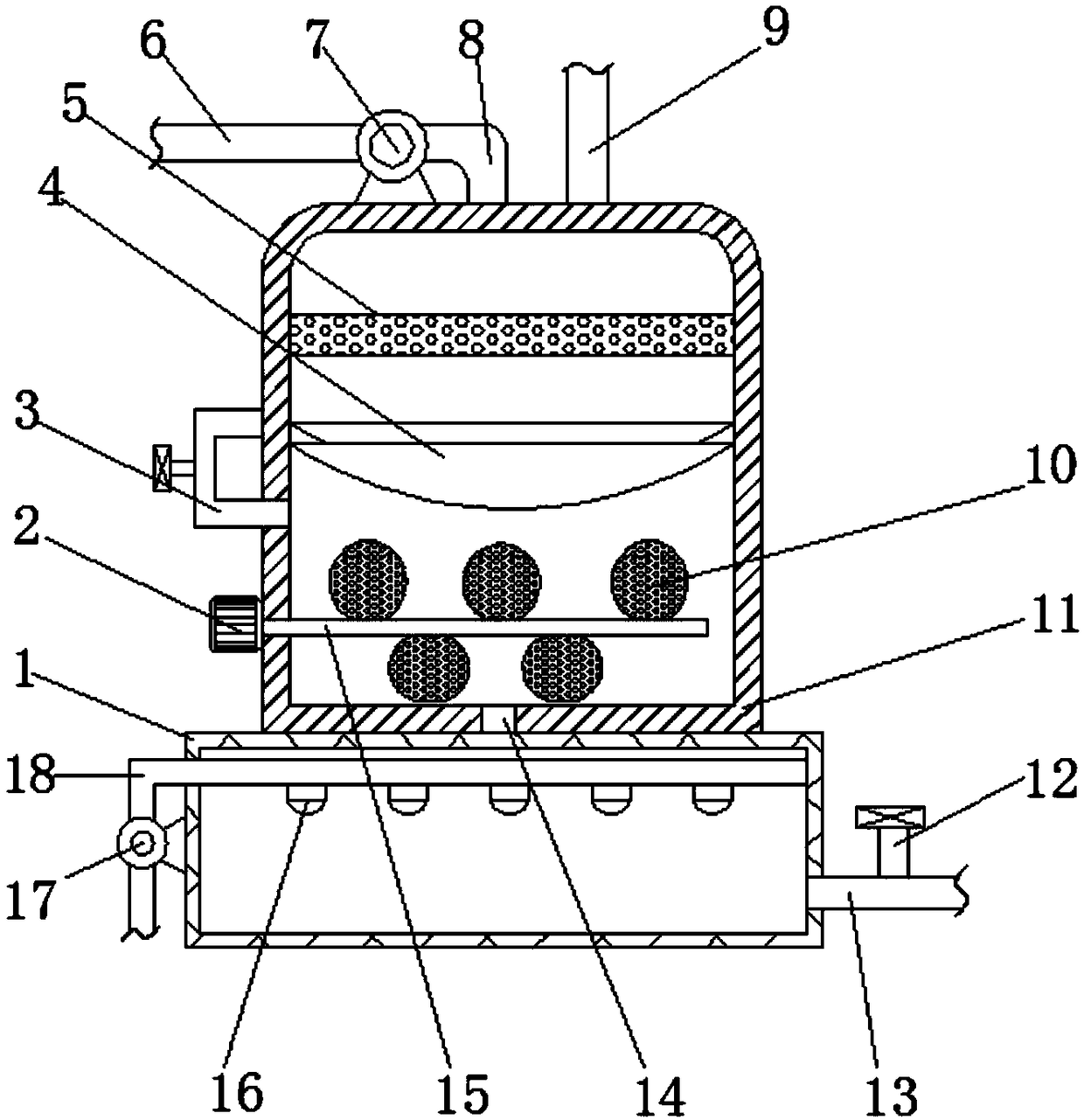

High-efficient purifying device for flue gas of coal-fired power plant and use method thereof

ActiveCN106000074APurify completelyImprove purification efficiencyElectrostatic separationDispersed particle separationProcess engineeringAir blower

The invention discloses a high-efficient purifying device for flue gas of a coal-fired power plant and a use method thereof. The high-efficient purifying device comprises a first purifying tank and a second purifying tank, wherein a supporting plate is arranged in the first purifying tank; a through hole is formed in the supporting plate; a gas inlet pipe and a feeding gate are arranged on one side of the first purifying tank away from the second purifying tank; an oxidation air blower is arranged on the gas inlet pipe; a separating plate is arranged in the second purifying tank; the second purifying tank is divided into a left tank chamber and a right tank chamber by the separating plate; a gas baffle is arranged in the right tank chamber; the first purifying tank is communicated with the second purifying tank through a gas pipe; one end of the gas pipe away from the first purifying tank is bent and extended into the right tank chamber. The high-efficient purifying device for the flue gas of the coal-fired power plant has the advantages that the flue gas is more safely purified, the purifying efficiency of the flue gas is increased, the purifying degree of the flue gas is greatly increased, the flue gas is completely purified, the time of purifying the flue gas is shortened and the working efficiency is greatly increased.

Owner:DATANG HUAYIN ELECTRIC POWER

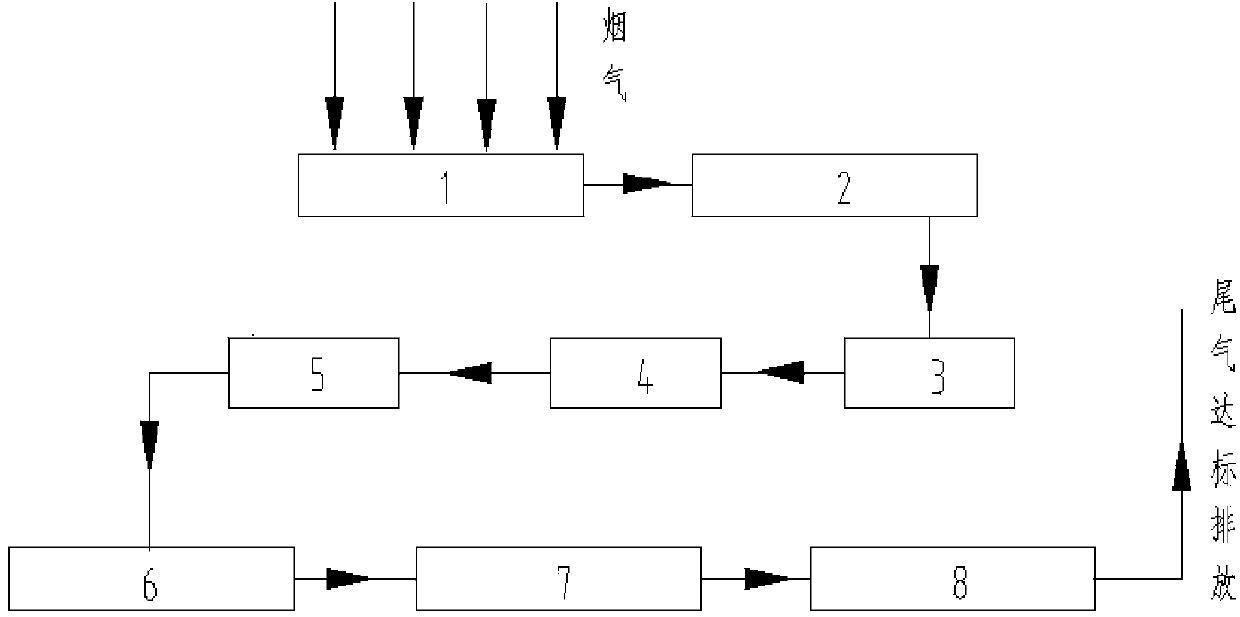

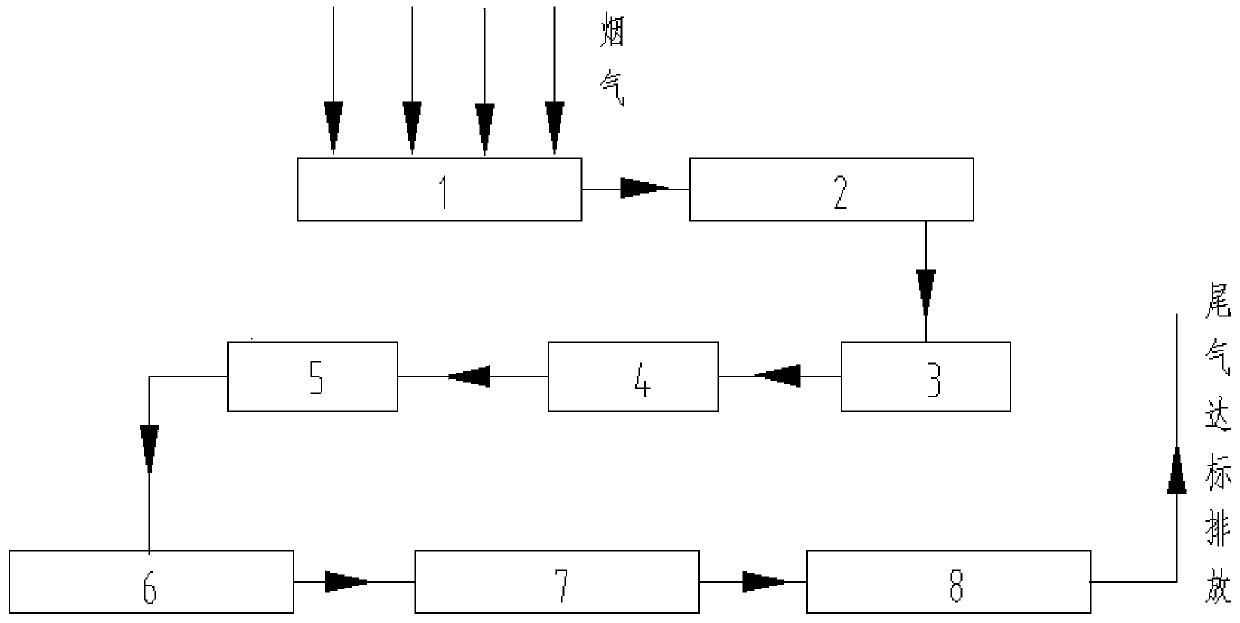

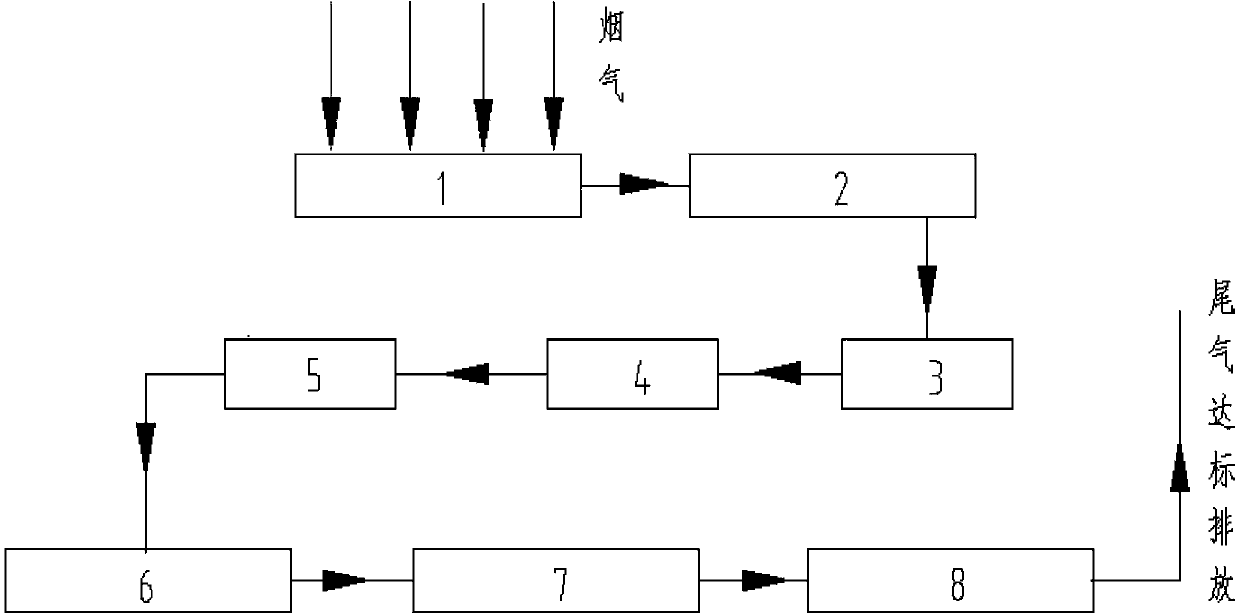

Method of recovering flue gas waste heat and dust in nonferrous metal smelting

ActiveCN103471405AHigh temperature resistance hasLow densityEnergy industryWaste heat treatmentCounter flowFiltration

The invention relates to a method of recovering flue gas waste heat and dust in nonferrous metal smelting and belongs to a method of waste heat utilization and waste gas treatment. A waste heat recovery device and a dust recovery device are formed by connecting a counter flow heat exchange waste heat boiler A, a silicon nitride porous ceramic filter, a counter flow heat exchange waste heat boiler B, a counter flow heat exchange waste heat boiler medium preheater, a plate type passage gas counter flow heat exchanger, a bag filter, and a draught fan through a pipeline or pipes; flue gas subjected to waste heat and dust recovery is subjected to sulfur recovery in a desulfurization shop, and the tail gas can be discharged standardly. The method includes the steps of primary waste heat recovery, filtration, dedusting and purification of high temperature flue gas, secondary waste heat recovery, tertiary waste heat recovery, quaternary waste heat recovery, low temperature filtration and dedusting, sulfur recovery, and emission of tail gas under national standard. The method has the advantages that waste heat recovery is efficient, dust recovery is complete, process control is simple, and recovery cost is low.

Owner:SHANDONG JINSHENG NON FERROUS GRP +1

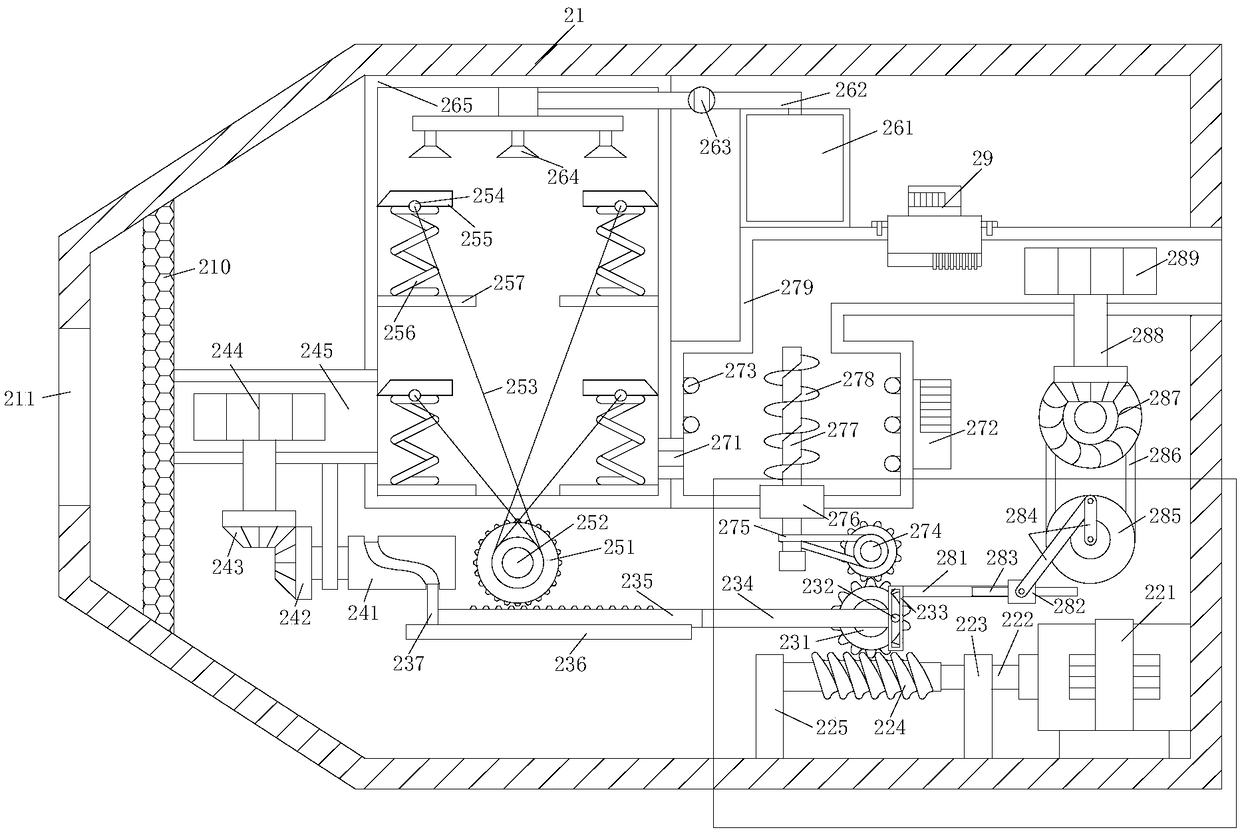

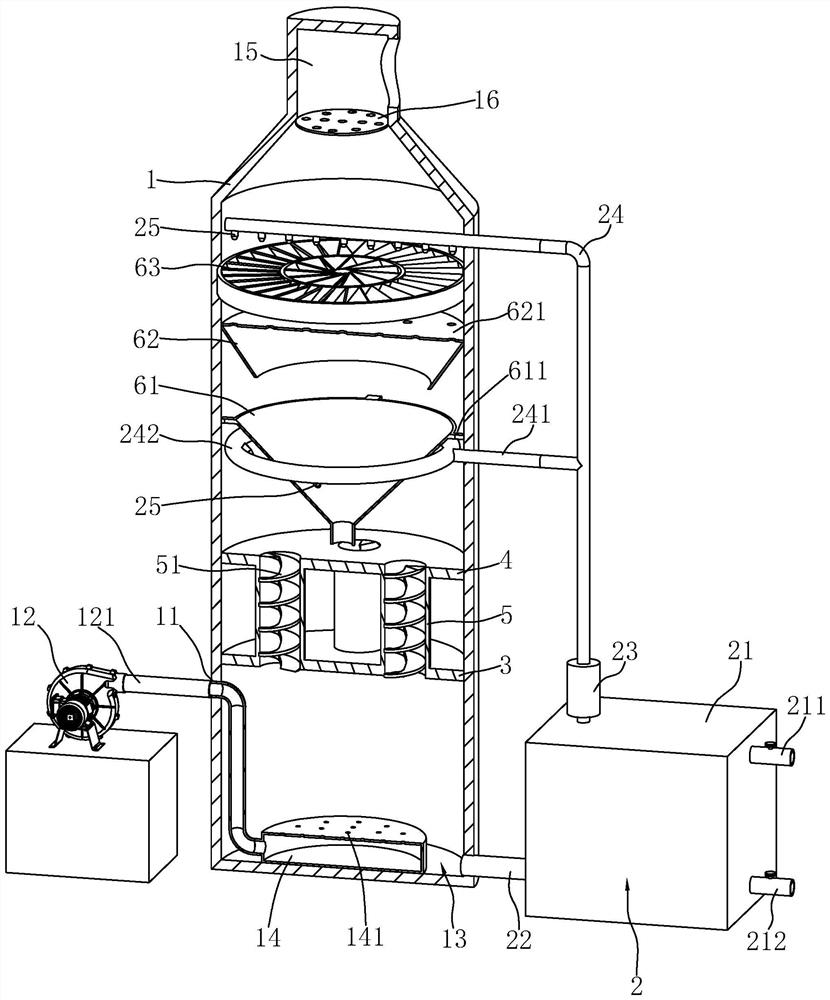

Atmospheric haze treatment device

ActiveCN111672259AIncrease contact timeImprove governance efficiencyCombination devicesAuxillary pretreatmentEngineeringMechanical engineering

The invention relates to an atmospheric haze treatment device. The device comprises a shell, the shell comprises an air inlet and a top air outlet, a spraying assembly for carrying out dust fall on haze is arranged in the shell, the spraying assembly comprises a dosing box arranged on one side of the shell, a dosing pump is arranged on one side of the dosing box, the dosing pump is communicated with a dosing pipe, the dosing pipe extends into the shell from the peripheral surface of the shell and is communicated with a plurality of spray heads, a first spoiler and a second spoiler which are used for spoiling gas are arranged in the shell, the first spoiler and the second spoiler are communicated with a plurality of flow uniformizing cylinders, the flow uniformizing cylinders enable the first spoiler and the second spoiler to penetrate through each other, and spiral blades are arranged in the flow uniformizing cylinders. The haze treatment device has the following advantages: the haze removal effect is good, and the haze treatment efficiency is improved.

Owner:北京北控生态建设集团有限公司

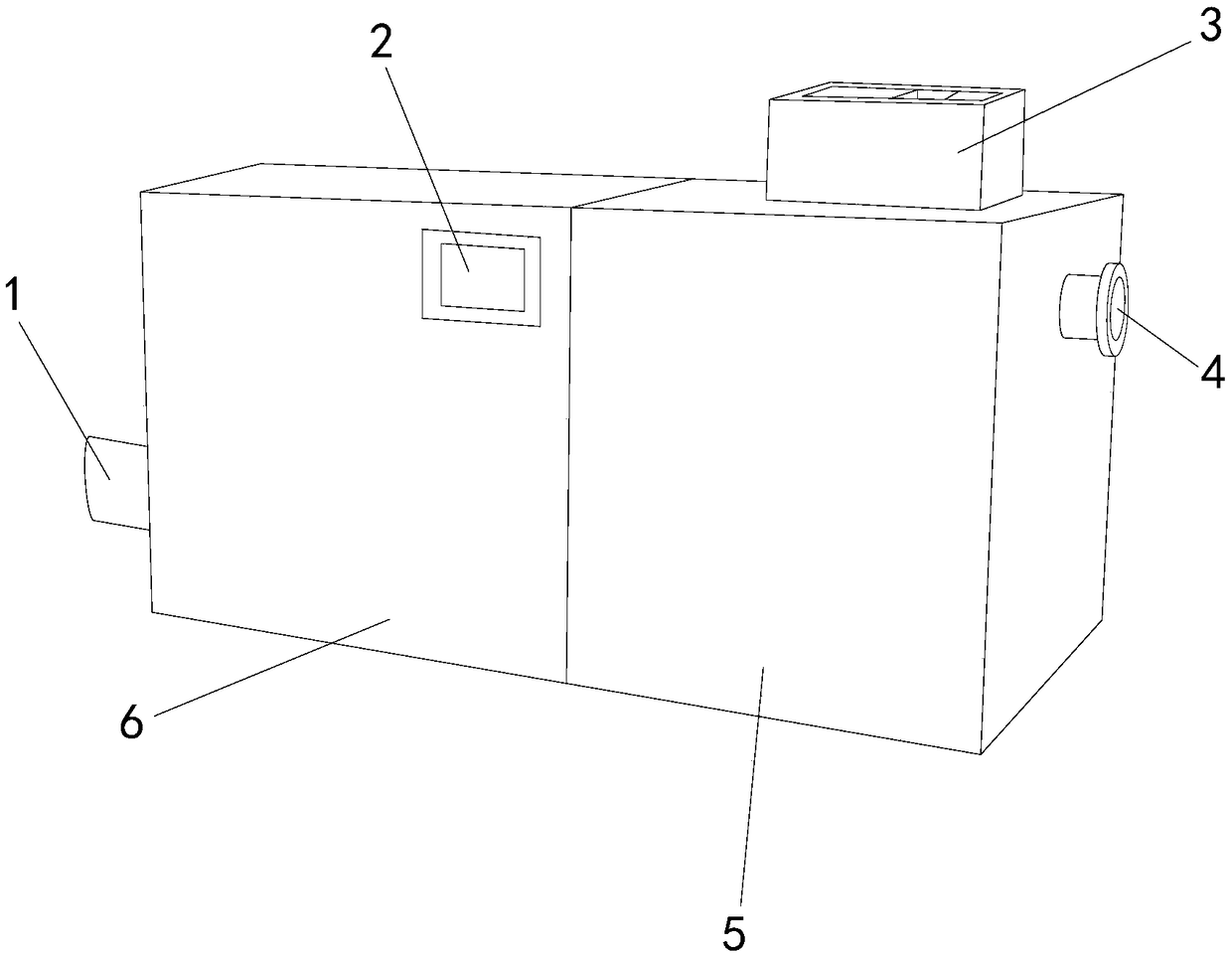

Gas filtration device for paint production

InactiveCN108654343AGuaranteed trackGuaranteed to workGas treatmentDispersed particle separationElectricityFiltration

The invention discloses a gas filtration device for paint production. The device structurally comprises a gas inlet, a main filtering machine, an operation panel, a box door, a purified gas outlet andsupporting legs, wherein the gas inlet is fixedly mounted at the head end of the main filtering machine, the operation panel is arranged on the front surface of the main filtering machine and is electrically connected through a wire, gas is sucked into a filtering plate through a gas inlet mechanism, the filtering plate preliminarily adsorbs particles, an agent spraying mechanism sprays an agentto gas, so that an agent and harmful substances in gas are mixed, the harmful substances are liquefied, gas is purified at the same time, a wall scraping mechanism is used for clearing the surface ofthe inner wall of the agent spraying mechanism, normal use of the agent spraying mechanism can be ensured, a liquid enters an evaporation mechanism for stirring evaporation after being formed, the evaporation effect is better, the harmful substances are more thoroughly purified, a negative-ion generator is used for final purification, and some harmful substances difficult to tackle are purified clean.

Owner:湖州御筵科技有限公司

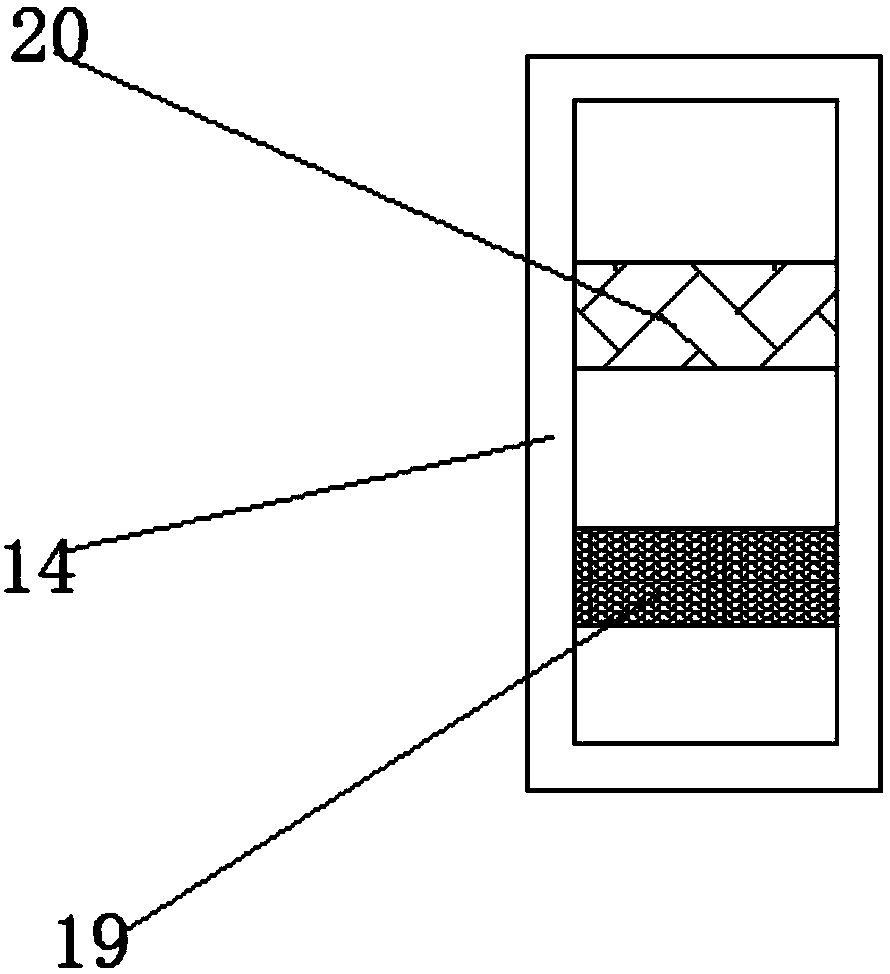

Cooking fume purification system for catering industry and household kitchens

InactiveCN104266247AStrong blocking powerPurify completelyDomestic stoves or rangesLighting and heating apparatusEngineeringSmall footprint

The invention provides a cooking fume purification system for the catering industry and household kitchens. The cooking fume purification system includes a casing, an air inlet in one side of the casing, and an air outlet in the other side, opposite to the air inlet, of the casing, wherein first separation zones, a second absorption zone and an oily water collection tank are arranged in the casing, the gas inlet of the first separation zones is connected with the air inlet of the casing, the end I, where a gas outlet is formed, of the first separation zones is connected with the inlet of the oily water collection tank, a spray pipe is arranged between the gas outlet of the first separation zones and the inlet of the oily water collection tank, and the other end II, opposite to the end I, of the first separation zones is connected with the second absorption zone. The cooking fume purification system for the catering industry and household kitchens provided by the invention has the advantages of simple structure, small occupied area, high cooking fume interception capability, complete purification, good cooling performance, long service life, and corrosion-resistant and fireproof performances; oil substances in cooking fume are removed through the filter net separation technique, and poisonous gases in the cooking fume are absorbed through the second absorption zone. The cooking fume purification system for the catering industry and household kitchens is applicable for both the catering industry and household kitchens.

Owner:LUOYANG LVREN ENVIRONMENTAL EQUIP

Novel automobile exhaust purification treatment device

InactiveCN107869372ANot easy to fall offAddress adverse effectsExhaust apparatusSilencing apparatusExhaust gasManipulator

The invention discloses a novel automobile exhaust gas purification treatment device, which comprises an exhaust pipe connecting ring, a connecting pipe and a first filter device, the top of the first filter device is fixedly connected with a pull ring, and the right side of the connecting pipe is fixedly connected to the exhaust gas purification device. An anechoic chamber, the exhaust gas purification and anechoic chamber is composed of a sound attenuation plate, the interior of the exhaust gas purification and anechoic chamber includes a second filter device, a third filter device and a fourth filter device, the right end of the exhaust gas purification and anechoic chamber is fixedly connected to an exhaust pipe, A power device is installed at the upper end of the exhaust gas purification and anechoic chamber, and the left side of the upper and lower ends of the exhaust gas purification and anechoic chamber are respectively fixedly connected with stiffeners. The mechanical arm is fixedly connected with the reinforcement ring, the rotating shaft is installed on the mechanical arm, and a reinforcement is added to make the exhaust gas purifier not easy to fall off; the multi-layer filter device design makes the exhaust gas purification more complete.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

Device for recycling waste heat and dust of metallic copper smelting flue gas

ActiveCN103471403ALow densityGood chemical stabilityIncreasing energy efficiencyWaste heat treatmentSilicon nitrideFlue gas

The invention discloses a device for recycling waste heat and dust of metallic copper smelting flue gas, and belongs to methods for utilizing waste heat and treating waste gas. A device for recycling the waste heat and a device for recycling the dust comprise a countercurrent heat-exchange waste heat boiler A, a silicon nitride porous ceramic filter, a countercurrent heat-exchange waste heat boiler B, a preheater for working media of the countercurrent heat-exchange waste heat boilers, a plate channel gas countercurrent heat exchanger, a bag filter collector and an induced draft fan which are connected with one another by pipelines or pipe fittings. The flue gas is desulfurized in a sulfuric acid workshop after the waste heat and the dust of the flue gas are recycled, and then tail gas meets standards and is exhausted. A method for recycling the waste heat and the dust of the metallic copper smelting flue gas includes steps of recycling waste heat at a first level; filtering high-temperature flue gas, removing dust of the high-temperature flue gas and purifying the high-temperature flue gas; recycling waste heat at a second level; recycling waste heat a third level; recycling waste heat at a fourth level; filtering low-temperature flue gas and removing dust of the low-temperature flue gas; feeding the filtered flue gas into the sulfuric acid workshop after the dust of the flue gas is removed, and desulfurizing the flue gas; enabling the tail gas to meet the standards and exhausting the tail gas. The device for recycling the waste heat and the dust of the metallic copper smelting flue gas has the advantages of high waste heat recycling efficiency, completeness in dust recycling, simplicity and convenience in process control and low recycling cost.

Owner:SHANDONG JINSHENG NON FERROUS GRP +1

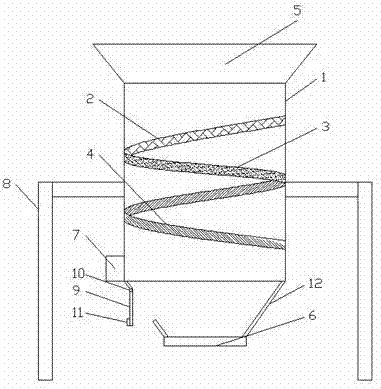

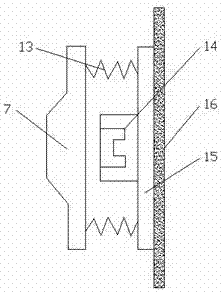

Spiral sieve net type filter

InactiveCN107875718AHEPA filterPurify completelyDispersed particle filtrationTransportation and packagingFiltrationPulp and paper industry

The invention discloses a spiral sieve net type filter. The spiral sieve net type filter structurally comprises a device body, a first spiral sieve net, a second spiral sieve net, a third spiral sievenet, a feeding port, a discharging port and a vibrator, wherein the feeding port is formed in the top of the device body, the first spiral sieve net is arranged in the device body, the second spiralsieve net is arranged at the bottom of the first spiral sieve net, the third spiral sieve net is arranged at the bottom of the second spiral sieve net, a discharging plate is arranged at the bottom ofthe third spiral sieve net, the discharging port is formed in the bottom of the discharging plate, and the vibrator is arranged on the left of the device body; resonant springs, an electromagnet anda base are arranged in the vibrator, the electromagnet is arranged in the vibrator, the resonant springs are welded between the vibrator and the electromagnet, and the base is arranged on the right ofthe electromagnet. The three spiral sieve nets of the spiral sieve net type filter can efficiently filter out impurities of a material, the filtration efficiency is improved and the filtration speedis increased.

Owner:ZHEJIANG HEADMAN FILTRATION TECH

Acidic gas recovering and purifying treatment device for chemical product research and development

InactiveCN108837676AReduce acidityAvoid pollutionGas treatmentDispersed particle separationEngineeringChemical products

The invention belongs to the technical field of gas purification and in particular relates to an acidic gas recovering and purifying treatment device for chemical product research and development. Inorder to solve the problem that a gas purifying treatment device is low in sterilizing ability, cannot adsorb peculiar smells and is low in work efficiency, the invention provides a scheme as follows:a first pump body is fixed to the outer wall of one side of a shell through a bolt, a first guide tube is welded to one end of a gas outlet of the first pump body, a first insertion hole is formed inthe outer wall of one side of the shell, the end, far away from the gas outlet, of the first guide tube is inserted into the first insertion hole, a second guide tube is welded to the one end of a gas inlet of the first pump body, a second insertion hole is formed in the outer wall of one side of the shell, and the second insertion hole is formed below the first pump body. The device provided bythe invention can reduce acidity of gas well to neutralize acidic gas so as to prevent the acidic gas from being discharged to pollute the environment, so that the ability of the device neutralizing gas is improved, and impurities and peculiar smells in gas can be adsorbed well.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

Water purificant

InactiveCN102050511ANo smellPurify completelyWater/sewage treatment using germicide/oligodynamic-processDisinfectantWater quality

The invention relates to a disinfectant, in particular to a purificant applied to drinking water. The purificant is prepared by the following raw materials in parts by weight: 30-40 parts of active carbon, 45-60 parts of hydrochloric acid, 12-30 parts of alum, 10-30 parts of ascorbic acid and 120-150 parts of water. The formula of the purificant is scientific and reasonable, the quality of purified water is good, aluminum, chlorine and other harmful heavy metal ions are not included, iron ion water phase transfer does not happen, the water body does not turn yellow; and the water purificant is nontoxic, unharmful, is completely reliable, has an excellent sterilization function, can be rapidly solved in water and release effective sterilization elements, and also has a strong sterilization effect on all kinds of intestinal pathogenic bacteria microorganisms in various natural waters.

Owner:杨羽

Array type jet flow water purifier

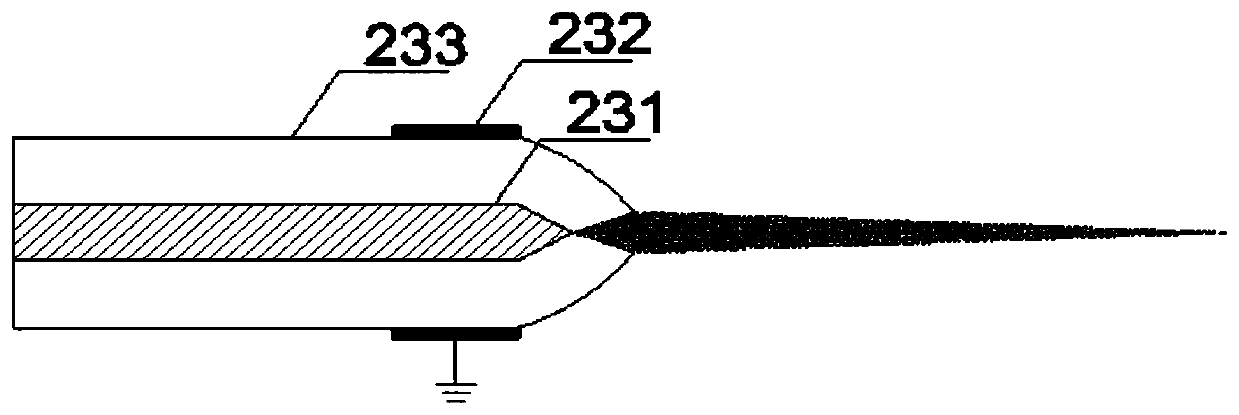

ActiveCN110642332AStable air intakeEasy maintenanceSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsPlasma jetSpray nozzle

The invention discloses an array type jet flow water purifier. A purifier frame body is arranged on a purification water tank, a first baffle plate and a second baffle plate are arranged in the purifier frame body, multiple layers of non-equilibrium plasma jet flow exciters are arranged between the first baffle plate and the second baffle plate, and the multiple non-equilibrium plasma jet flow exciters of each layer are distributed circumferentially; the area between the first baffle plate and the inner wall of the purifier frame body is an air inflow pressure stabilizing cavity, air inlets are formed in the purifier frame body, jet orifices are formed in the second baffle plate, one end of each non-equilibrium plasma jet flow exciter is fixed on the first baffle plate, and spray nozzles are arranged the other ends of the non-equilibrium plasma jet flow exciters and aligned to the corresponding jet orifices; and an internal area defined by the second baffle plate is a purification area. With the adoption of the technical scheme of the liquid atomization technology and the non-equilibrium plasma jet flow technology, the purification efficiency can be substantially increased, and thepurification flow rate can also be greatly increased.

Owner:DALIAN NATIONALITIES UNIVERSITY

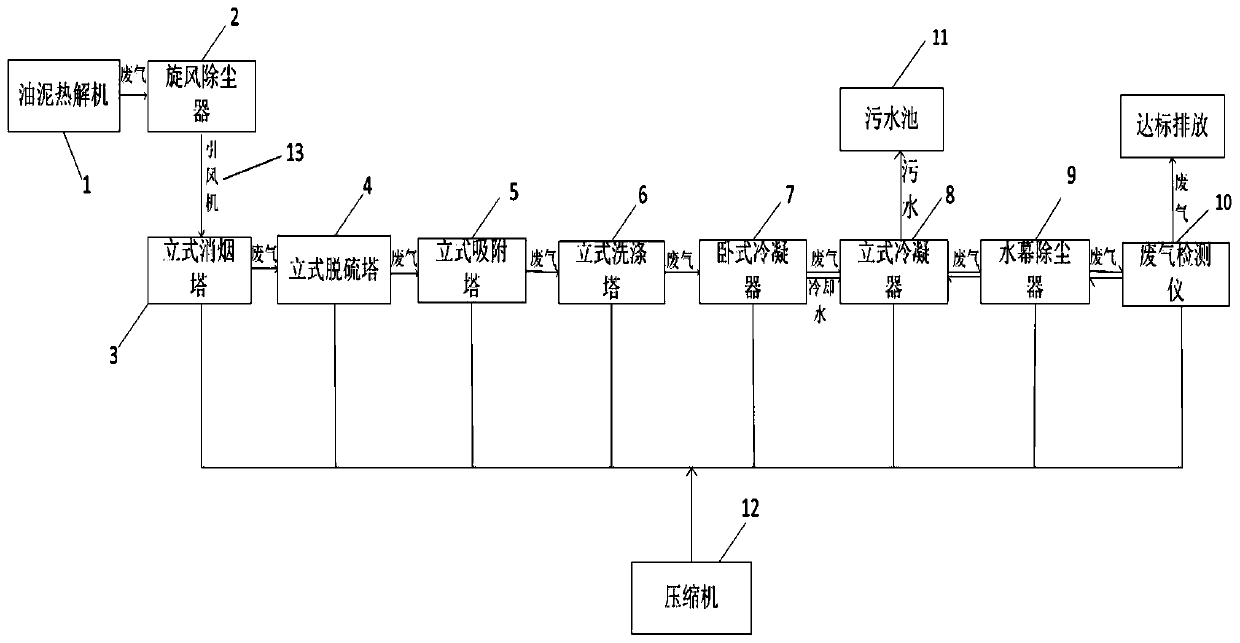

Exhaust gas treatment technology

The invention provides an exhaust gas treatment technology. The technology comprises the steps of waste gas dust removal, wherein waste gas is introduced into a cyclone dust collector, and waste gas is introduced into a smoke abatement tower and subjected to participate precipitation by the smoke abatement tower; waste gas desulfurization, wherein waste gas obtained after dust removal is introduced into a desulfurization tower and subjected to desulfurization treatment by the desulfurization tower; waste gas purification, wherein waste gas obtained after desulfurization is introduced into an adsorption tower, harmful gas is absorbed away by the adsorption tower, and the waste gas is introduced into a washing tower to be further purified; waste gas condensation, wherein waste gas obtained after purification is introduced into a horizontal condenser and a vertical condenser in success for condensation and liquidation; secondary waste gas dust removal, wherein waste gas obtained after condensation is introduced into a water curtain dust collector for secondary dust removal; waste gas detection, wherein waste gas obtained after secondary dust removal is introduced into a waste gas detector for detection, waste gas is detected to reach the standard and exhausted, otherwise, waste gas is introduced into the water curtain dust collector for dust removal again, and the steps are repeatedly executed till waste gas reaches the standard to be exhausted.

Owner:中科天龙(厦门)环保股份有限公司

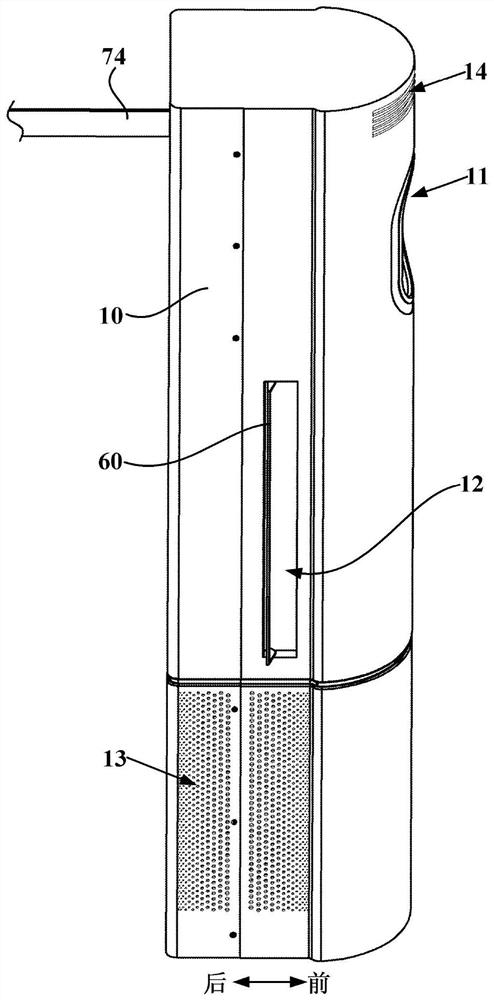

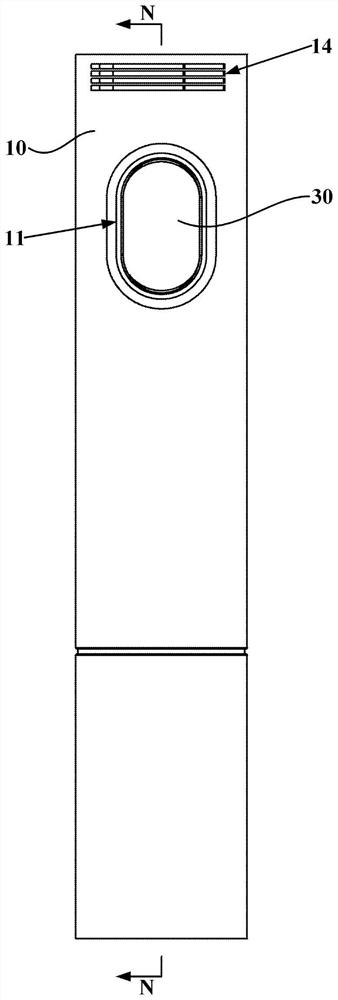

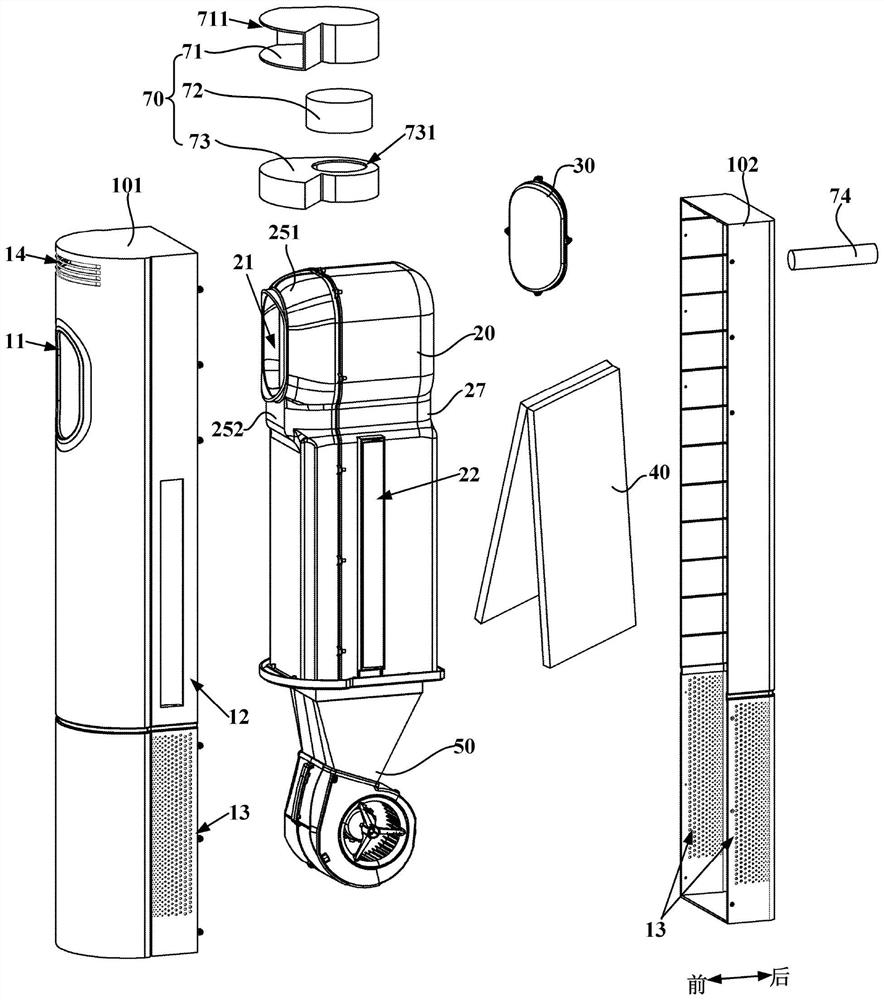

Vertical air conditioner indoor unit

InactiveCN111912020AFast winding speedStrong windDucting arrangementsLighting and heating apparatusFresh airEnvironmental engineering

The invention provides a vertical air conditioner indoor unit. The vertical air conditioner indoor unit comprises a shell, a fresh air module, an air duct and a flow guide piece. A fresh air supply outlet and a gathering air supply outlet are arranged up and down on the front side of the shell. The fresh air module is arranged in the shell and is configured to introduce fresh air and blow the fresh air out of the fresh air supply outlet. The air duct is arranged in the shell. The air duct is provided with an air inlet and a first air outlet facing the gathering air supply outlet and used for guiding airflow in the shell to the gathering air supply outlet. The inner wall, close to the first air outlet, of the air duct is in a gradually-reduced shape with an overflowing section gradually reduced in the airflow direction. The flow guide piece is arranged in the air duct. An annular air supply outlet gap is defined by the flow guide piece and a gradually-shrinking part of the flow guide piece. The flow guide piece is used for guiding the airflow to the annular air supply outlet gap, so that the airflow is gradually gathered towards an airflow center under the guidance of the inner wallof the air duct and sequentially flows out of the first air outlet and the gathering air supply outlet. The vertical air conditioner indoor unit has better long-distance air supply and strong air supply effects.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Medical wastewater treatment method

ActiveCN110510706AHigh killing efficiencyReduce use costWater treatment parameter controlSpecific water treatment objectivesPlasma jetElectronic controller

The invention discloses a medical wastewater treatment method which comprises the following steps: S1, arranging multiple layers of non-balance plasma jet flow stimulator on a jet flow purifier; S2, supplying power to each high-voltage electrode through a plasma power supply; S3, controlling a gas flow control valve a and a gas flow control valve b to be opened by a valve opening degree electroniccontroller; S4, controlling a liquid flow control valve to be opened by a valve opening degree electronic controller, and feeding a liquid to be treated in a liquid storage tank into an action spaceof array non-balance plasma jet flows; S5, under the action of the non-balance plasma jet flow, killing a target purification substance in liquid droplet granules in an atomization field; S6, collecting liquid spray purified by the array non-balance plasma jet flows in a water treatment tank; and S7, opening a detection hole control valve, pumping out a liquid after purification by using a detection hole refluxing pump, and feeding the liquid into a detection unit. The non-balance plasma technique has the characteristics of being high in killing efficiency, low in pathogene regeneration rate,low in use cost, and the like, and is a completely new efficient and clean water purification technique.

Owner:DALIAN NATIONALITIES UNIVERSITY

Method for recycling waste heat and dust of metallic copper smelting flue gas

ActiveCN103471406AReduce recycling costsFull recoveryIncreasing energy efficiencyWaste heat treatmentIn process controlPorous ceramics

The invention discloses a method for recycling waste heat and dust of metallic copper smelting flue gas, and belongs to methods for utilizing waste heat and treating waste gas. A device for recycling the waste heat and a device for recycling the dust comprise a countercurrent heat-exchange waste heat boiler A, a silicon nitride porous ceramic filter, a countercurrent heat-exchange waste heat boiler B, a preheater for working media of the countercurrent heat-exchange waste heat boilers, a plate channel gas countercurrent heat exchanger, a bag filter collector and an induced draft fan which are connected with one another by pipelines or pipe fittings. The flue gas is desulfurized in a sulfuric acid workshop after the waste heat and the dust of the flue gas are recycled, and then tail gas meets standards and is exhausted. The method includes steps of recycling waste heat at a first level; filtering high-temperature flue gas, removing dust of the high-temperature flue gas and purifying the high-temperature flue gas; recycling waste heat at a second level; recycling waste heat at a third level; recycling waste heat at a fourth level; filtering low-temperature flue gas and removing dust of the low-temperature flue gas; feeding the filtered flue gas into the sulfuric acid workshop after the dust of the flue gas is removed, and then desulfurizing the flue gas; enabling the tail gas to meet the standards and exhausting the tail gas. The method for recycling the waste heat and the dust of the metallic copper smelting flue gas has the advantages of high waste heat recycling efficiency, completeness in dust recycling, simplicity and convenience in process control and low recycling cost.

Owner:SHANDONG JINSHENG NON FERROUS GRP +1

A horizontal bypass dedusting denitrification and desulfurization device

ActiveCN104984653BReasonable structureEasy to disengageDispersed particle separationExternal electric electrostatic seperatorEngineeringTuyere

The invention discloses a horizontal circle-flow dust-removal denitration desulphurization apparatus. The horizontal circle-flow dust-removal denitration desulphurization apparatus comprises a shell, a dust removal chamber, a denitration chamber, a desulphurization chamber and a drying chamber, wherein the dust removal chamber, the denitration chamber, the desulphurization chamber and the drying chamber are installed in the shell, an air inlet is formed in the left side of the dust removal chamber, a dust collection polar plate and a cathode filament rod are installed in the dust removal chamber, an electromagnetic vibrator is installed above the dust removal chamber, an ash bucket is installed below the dust removal chamber, the denitration chamber is arranged at the right side of the dust removal chamber, a denitration liquid spraying device is installed above an inner chamber of the denitration chamber, the right side of the denitration chamber is provided with a denitration liquid storage groove, the right side of the denitration liquid storage groove is provided with a desulphurization liquid storage groove, the right side of the desulphurization liquid storage groove is provided with the desulphurization chamber, a desulphurization liquid spraying device is installed above an inner chamber of the desulphurization chamber, the right side of the desulphurization chamber is provided with a drying chamber, and the right side surface of the drying chamber is provided with an exhaust apparatus. The horizontal circle-flow dust-removal denitration desulphurization apparatus is simple in structure, easy to repair and maintain and capable of improving the purifying quality of the air.

Owner:YIXING HAINA ENVIRONMENTAL ENG

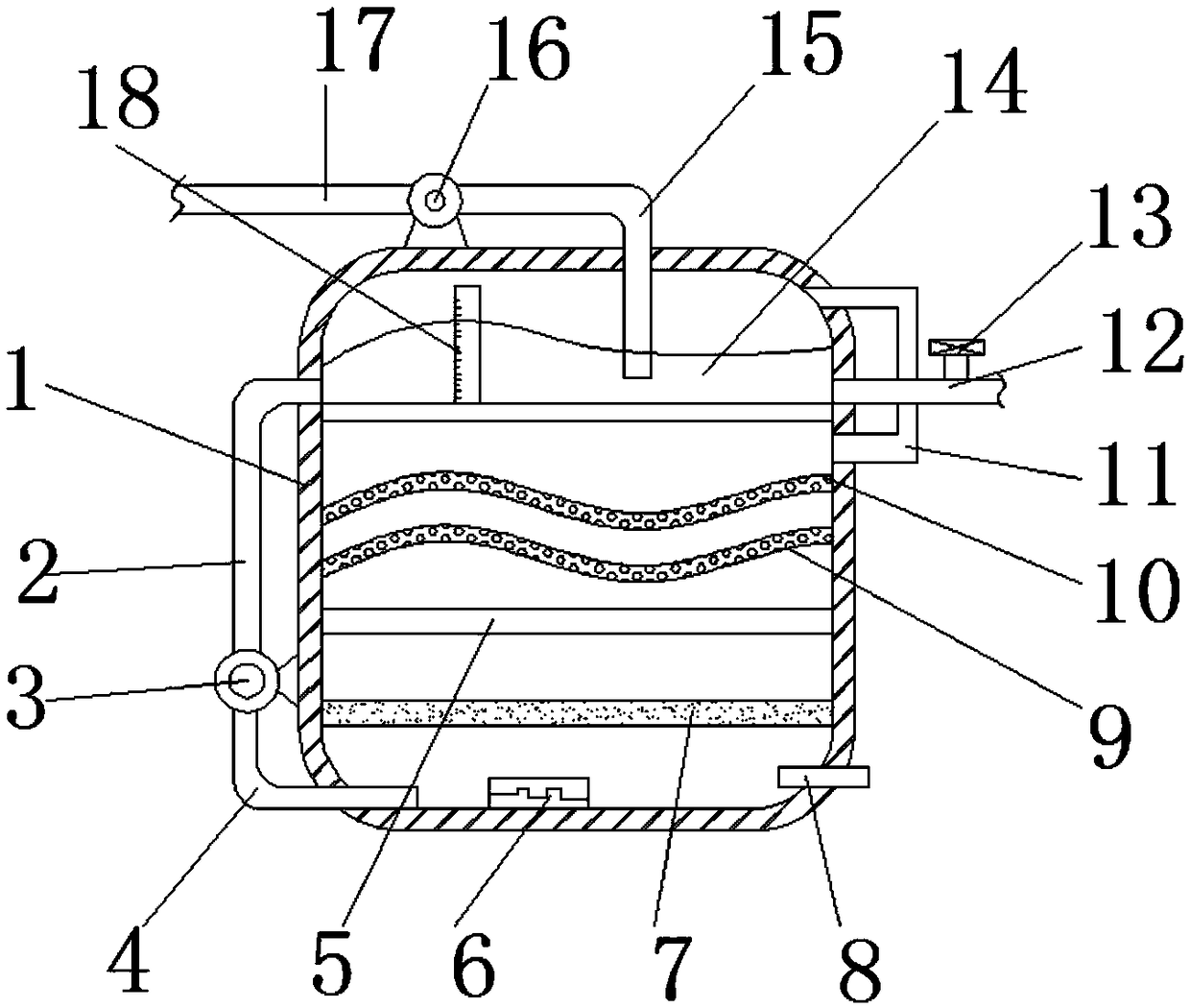

Microorganism sewage purification processing device

InactiveCN107089778APurify completelyPrevent backflowTreatment involving filtrationMultistage water/sewage treatmentWater pipeCheck valve

The invention discloses a microorganism sewage purification processing device which comprises a device body. A water inlet pipe is arranged at one side above the device body; a chlorine inlet pipe is arranged at the other side of the water inlet pipe; a chlorine sterilization chamber is formed at the upper part inside the device body; the other side of a microorganism processing chamber is connected with a vent pipe. In the invention, the chlorine sterilization chamber, a filtering chamber and the microorganism processing chamber are sequentially arranged inside the microorganism sewage purification processing device from top to bottom, so that impurity removal and purification processing can be respectively carried out on sewage to a certain degree; four water tanks are arranged in the microorganism processing chamber, so that the sewage can uniformly fall into the water tanks; a microorganism processing bacteria solution is uniformly dropped into the four water tanks from a microorganism processing bacteria solution catheter via four droppers, so that uniform release of the microorganism processing bacteria solution can be ensured; arrangement of check valves in the droppers can prevent sewage backflow.

Owner:CHENGDU YANXINGGUO TECH CO LTD

A device for controlling atmospheric smog

ActiveCN111672259BIncrease contact timeImprove governance efficiencyCombination devicesAuxillary pretreatmentThermodynamicsHelical blade

The invention relates to an atmospheric haze treatment device, which comprises a casing, the casing includes an air inlet and a top air outlet, and a spray assembly for dust reduction of the haze is arranged inside the casing, and the spray assembly includes A dosing box arranged on one side of the casing, a dosing pump is arranged on one side of the dosing box, and the dosing pump is connected with a dosing pipe, and the dosing pipe goes deep into the shell from the peripheral surface of the casing There are a number of nozzles connected to the inside of the body, and a first baffle plate and a second baffle plate that block the flow of gas are arranged in the housing, and a number of uniform flow plates are connected to the first baffle plate and the second baffle plate. The uniform flow cylinder penetrates the first baffle and the second baffle, and the uniform flow cylinder is provided with helical blades. The invention has the advantages that the effect of removing haze is better, and the efficiency of haze control is improved.

Owner:北京北控生态建设集团有限公司

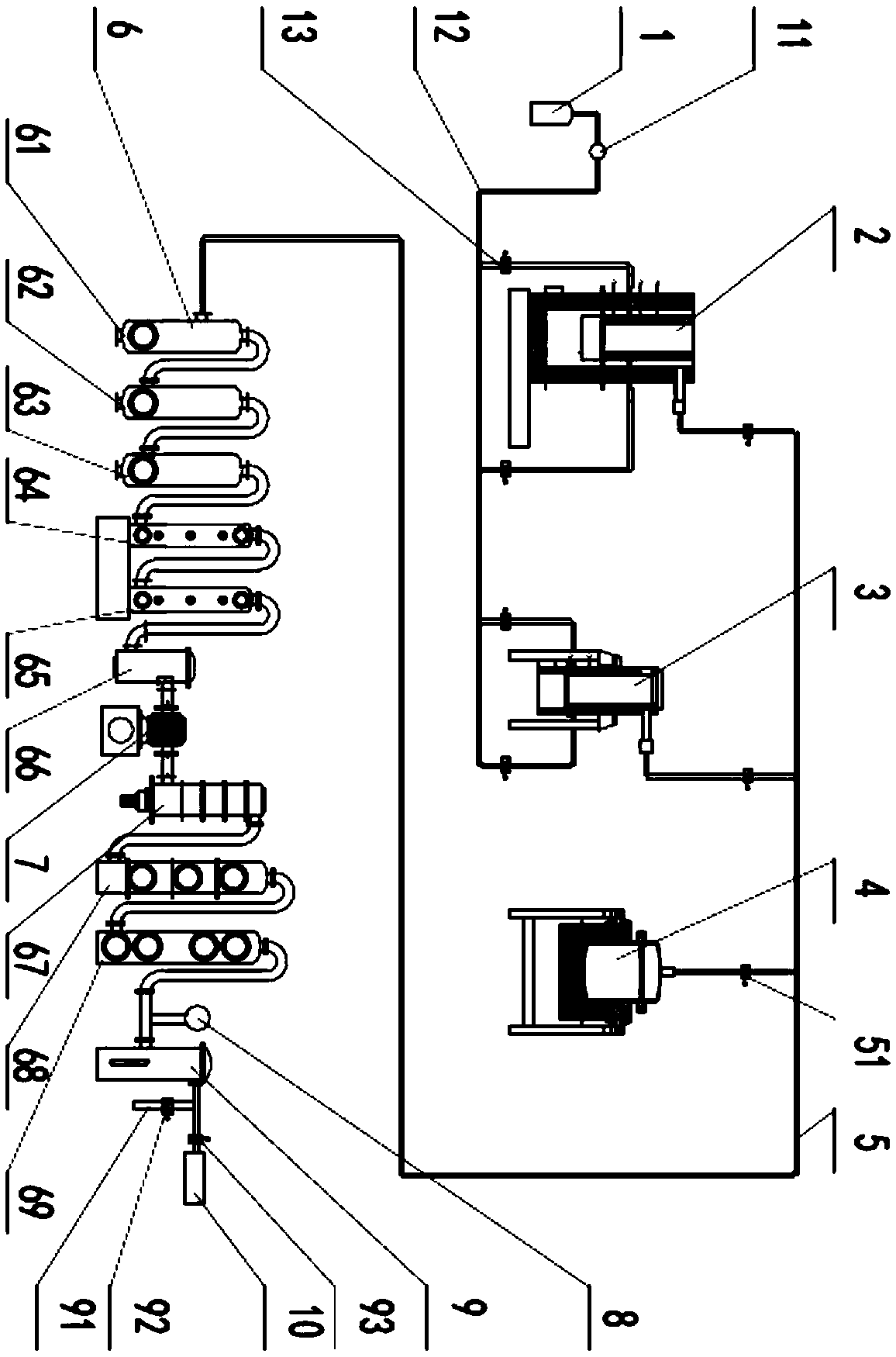

Carbon gas and liquid joint production device using biomass pyrolysis and gasifying for teaching or scientific study

PendingCN109111937AHigh speedGood effectBiofuelsSpecial form destructive distillationScientific studyBiomass fuels

The invention discloses a carbon gas and liquid joint production device using biomass pyrolysis and gasifying for teaching or scientific study. The carbon gas and liquid joint production device comprises a steam generator, a lower absorption type gasifying furnace, an upper absorption type gasifying furnace, a dry distillation furnace, gas pipelines, a purifying system, an induced draft fan, a gasflowmeter, a combined water seal tank and a combustor, wherein the purifying system comprises three condensing towers, two water scrubbing humidifying towers, a precipitating tank and three tar removal towers which are serially connected by the gas pipelines; the lower absorption type gasifying furnace, the upper absorption type gasifying furnace and the dry distillation furnace are respectivelyconnected with the front ends of the gas pipelines through pipelines; the purifying system is connected with the middle part of the gas pipeline, and the induced draft fan is serially connected with aconnecting pipeline of the purifying system; the tail end of each gas pipeline is sequentially connected with a gas flowmeter, a combined water seal tank and a combustor. The carbon gas and liquid joint production device has the advantages that one complete set of laboratory-level biomass gasifying and purifying equipment is provided; powder particles and biological oil can be separated, by the purifying system, from combustible gas generated after gasifying biomass fuel, and the clean combustible gas is obtained.

Owner:德博尔特(天津)科技有限公司

A filter material for deep purification of drinking water

ActiveCN110002520BUniform flow rateEven contactTreatment involving filtrationWater/sewage treatment by sorptionDisinfection by-productMolecular materials

The invention discloses a filter material for deep purification of drinking water, which comprises an upper support layer, a lower support layer and an amphiphilic polymer material filled between them, and the upper support layer and the lower support layer are both porous plates , the average particle size of the amphiphilic polymer material is 5 to 500 microns, and the amphiphilic polymer material in the filter material of the present invention is effective against novel environmental pollution such as antibiotics, endocrine disruptors, disinfection by-products, environmental hormones, and pesticides. The removal rate of pollutants is over 99%.

Owner:JIANGSU GUOCHUANG ENVIRO PROTECTION TECH CO LTD

A method for simultaneous determination of 19 organochlorine pesticide residues in Panax notoginseng

ActiveCN108061774BReduce usageThe processing method is completelyComponent separationGas liquid chromatographicPesticide residue

Owner:TIANJIN TASLY PHARMA CO LTD

Device for purifying vinosity

InactiveCN101948732BImprove inner qualityReduce flow rateAlcoholic beverage preparationUltraviolet lightsSolid particle

Owner:李建东

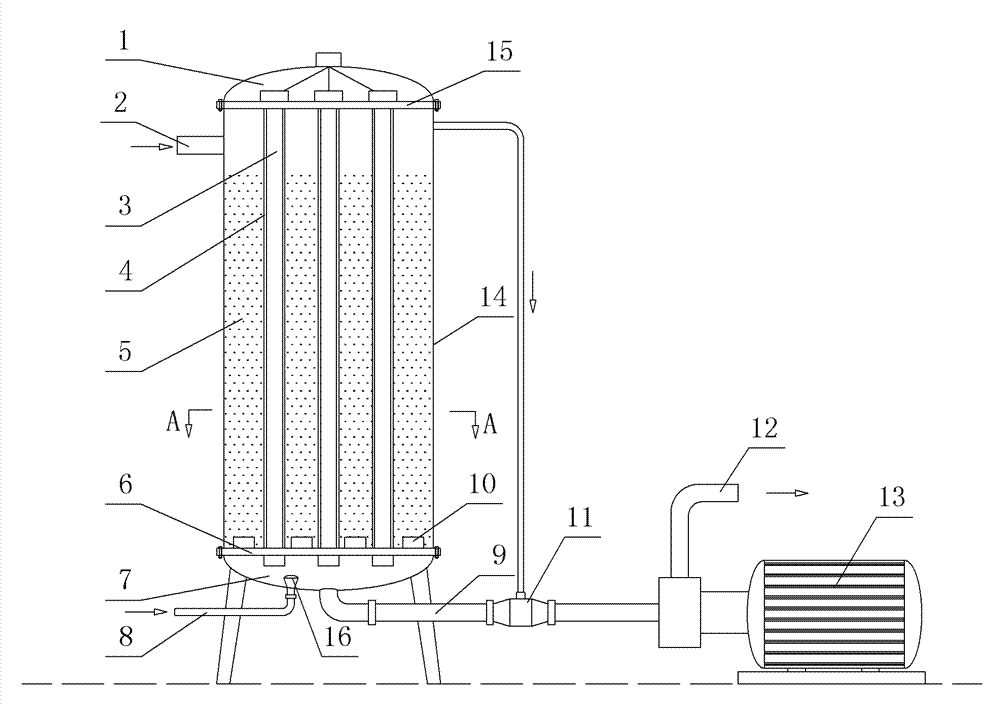

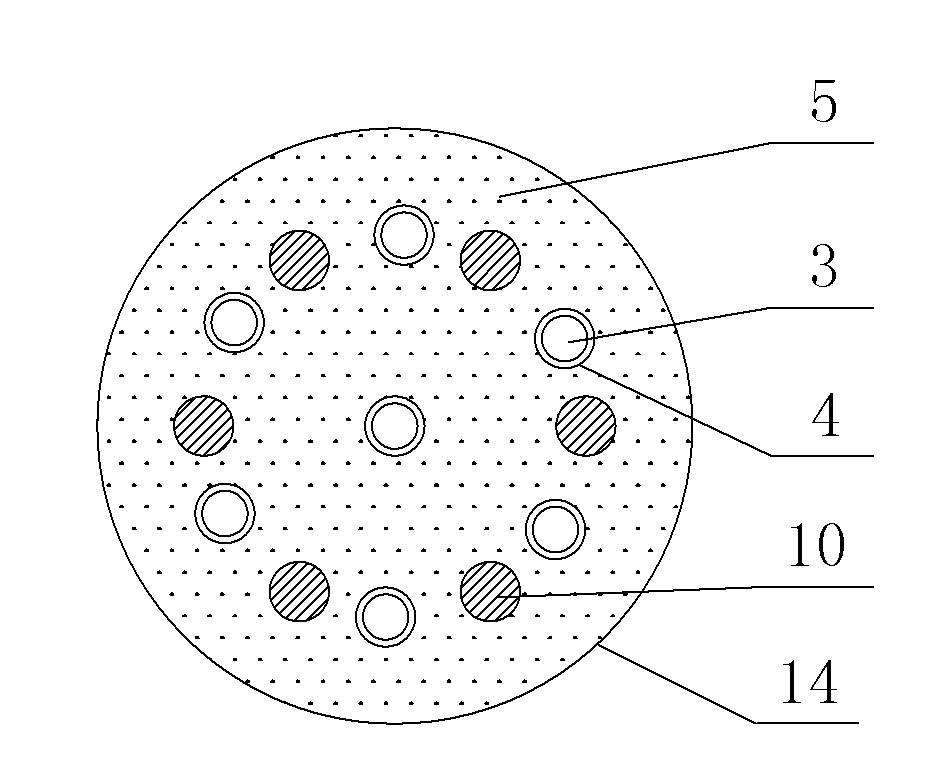

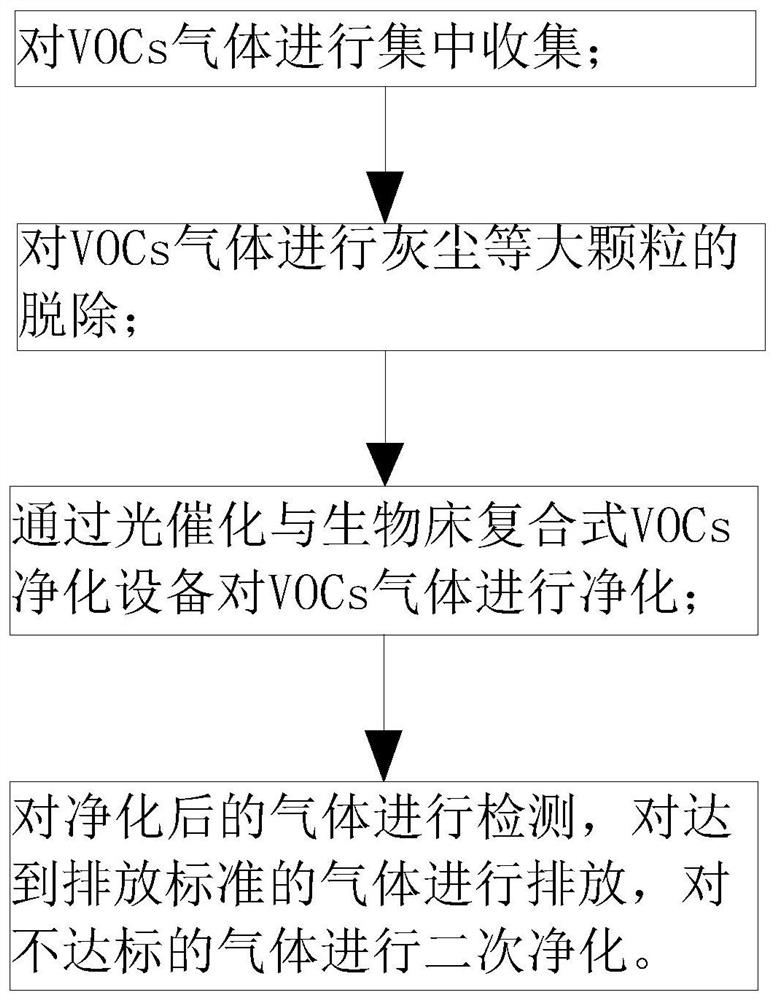

A kind of purification method of vocs gas

ActiveCN108905565BImprove purification rateAvoid secondary pollutionGas treatmentDispersed particle separationPurification methodsEmission standard

The invention belongs to the technical field of VOCs gas treatment, and specifically relates to a method for purifying VOCs gas. The method includes the following steps: collecting VOCs gas in a concentrated manner; removing large particles such as dust from VOCs gas; The biological bed compound VOCs purification equipment purifies VOCs gas; detects the purified gas, discharges the gas that meets the emission standard, and performs secondary purification on the gas that does not meet the standard; the invention is suitable for the purification of a large amount of VOCs gas , At the same time, the purification rate of the present invention is high, effectively avoiding the harm of VOCs gas to the environment and human beings.

Owner:NANJING DOULE REFRIGERATION EQUIP

Non-ferrous metal smelting flue gas waste heat and dust recycling device

ActiveCN103471404BImprove waste heat recovery efficiencyReduce recycling costsIncreasing energy efficiencyWaste heat treatmentCounter flowFiltration

The invention relates to a unit of recovering flue gas waste heat and dust in nonferrous metal smelting and belongs to a method of waste heat utilization and waste gas treatment. A waste heat recovery device and a dust recovery device are formed by connecting a counter flow heat exchange waste heat boiler A, a silicon nitride porous ceramic filter, a counter flow heat exchange waste heat boiler B, a counter flow heat exchanger waste heat boiler medium preheater, a plate type passage gas counter flow heat exchanger, a bag filter, and a draught fan through a pipeline or pipes; flue gas subjected to waste heat and dust recovery is subjected to sulfur recovery in a desulfurization shop, and the tail gas can be discharged standardly. The method includes the steps of primary waste heat recovery, filtration, dedusting and purification of high temperature flue gas, secondary waste heat recovery, tertiary waste heat recovery, quaternary waste heat recovery, low temperature filtration and dedusting, sulfur recovery and emission of tail gas under national standard. The device has the advantages that waste heat recovery is efficient, dust recovery is thorough, process control is simple, and recovery cost is low.

Owner:SHANDONG JINSHENG NON FERROUS GRP +1

Sewage purifying device adopting microorganism technique

InactiveCN108658380AEffective rotary aerationPurify thoroughlyTreatment using aerobic processesSpecific water treatment objectivesMicroorganismSewage

The invention discloses a sewage purifying device adopting a microorganism technique. The sewage purifying device comprises a casing, wherein an installation hole is formed in the outer wall of one side of the casing; a water drain hole is formed in the outer wall of one side of the casing; a water drain pipe is fixedly arranged at the inner wall of one side of the water drain hole via a bolt; a control valve is fixedly arranged at the outer wall of the top part of the water drain pipe through a bolt; a first water pump is fixedly arranged at the outer wall of one side of the casing through abolt, and is positioned under the installation hole; a disinfection pipe is welded with one end of a water outlet of the first water pump; one end, away from the water outlet, of the disinfection pipeis inserted into the installation hole. The sewage purifying device has the advantages that aeration blades are effectively driven to rotate and aerate, so that the impurities in the sewage can be better separated from a water body, the sewage is more thoroughly purified, and the working efficiency is improved; the purified sewage can be effectively disinfected; the pollution to surrounding environments is reduced in the drainage process, the sewage can be reutilized, and the energy-saving and environment-friendly properties are improved.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Industrial wastewater biological membrane multi-stage treatment device

InactiveCN108298678AComplete controlReasonable controlWater/sewage treatmentMultistage water/sewage treatmentIndustrial waste waterBiological membrane

The invention discloses an industrial wastewater biological membrane multi-stage treatment device which structurally comprises a water outlet tube, a control panel, a purification medicine holding cabin, a water inlet tube, a biological membrane treatment water cabin and a multi-stage purification water cabin, wherein the water outlet tube is mounted on the left side of the multi-stage purification water cabin and is welded with the multi-stage purification water cabin; the multi-stage purification water cabin is a rectangle; the control panel is arranged above the right part of the front sideof the multi-stage purification water cabin; the multi-stage purification water cabin is buckled with the control panel; the biological membrane treatment water cabin is arranged on the right side ofthe multi-stage purification water cabin; the multi-stage purification water cabin is locked with the biological membrane treatment water cabin; the biological membrane treatment water cabin is mounted below the purification medicine holding cabin and is in clearance fit with the purification medicine holding cabin; the biological membrane treatment water cabin is a rectangle. When the equipmentis used, through a medicine control mechanism, the problems that purification medicines can be mixed in advance when being not stored independently, and medicines are not completely purified since theholding ratios are not precise, can be avoided, and the equipment can be relatively reasonable in medicine control and relatively complete in purification.

Owner:谢彬彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com