Array type jet flow water purifier

A water purifier, array type technology, applied in the direction of water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., can solve the problems of slow purification rate, poor diffusivity, easy corrosion and failure of electrodes, and achieve convenience Overhaul, improve purification efficiency, and improve the effect of purification flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

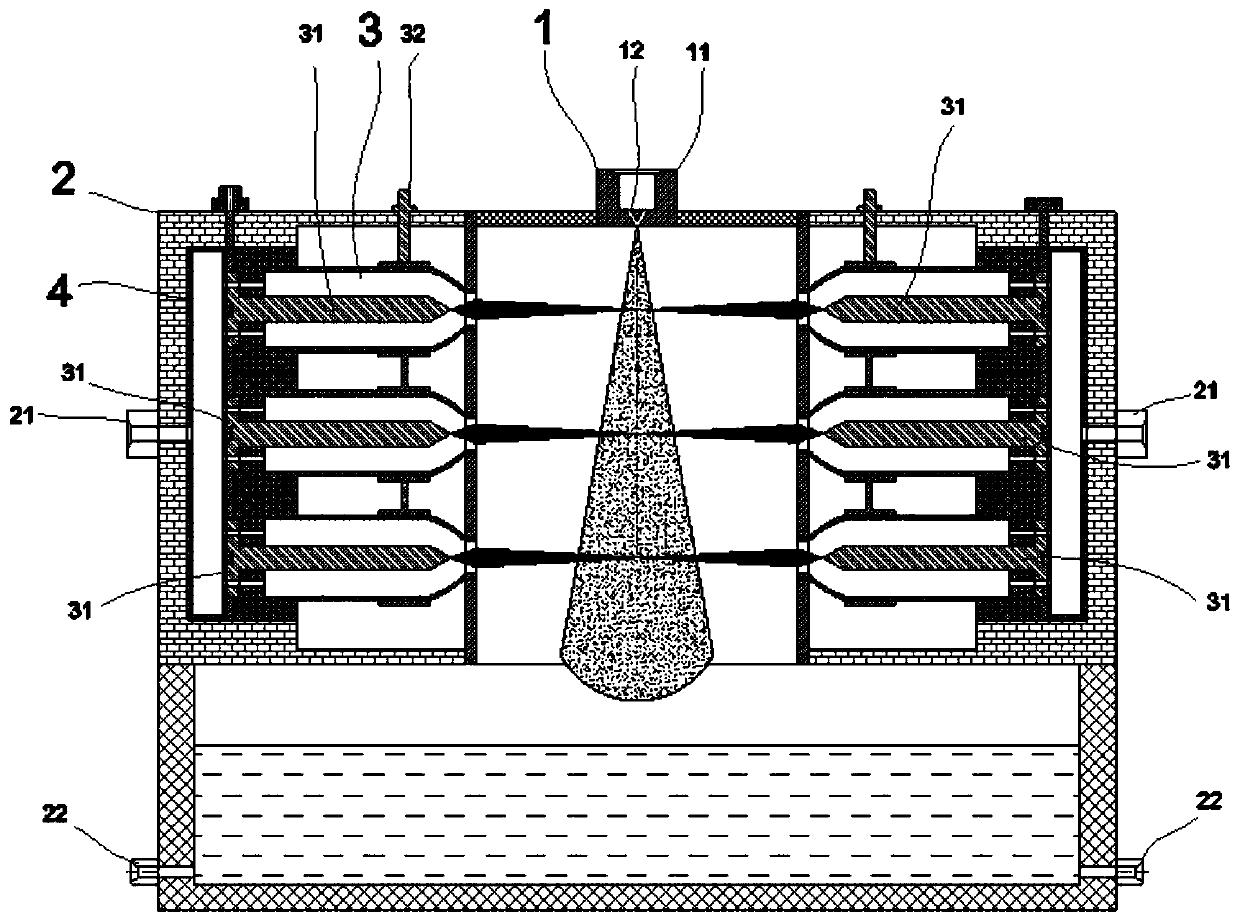

[0021] This embodiment provides an array jet water purifier, comprising: a liquid atomizer, a purifier frame, an unbalanced plasma jet exciter, an air intake stabilizing chamber and a purified water tank, and a purifier is arranged on the purified water tank frame body, a first baffle plate and a second baffle plate are arranged in the purifier frame body, and a multi-layer unbalanced plasma jet exciter is arranged between the first baffle plate and the second baffle plate, and the multiple layers of each layer The two unbalanced plasma jet exciters are distributed in a circle; the area between the first baffle plate and the inner wall of the purifier frame is an air intake plenum, and an air inlet is processed on the purifier frame, and the second A jet port is processed on the baffle, one end of the unbalanced plasma jet actuator is fixed on the first baffle, and the other end of the unbalanced plasma jet actuator is an ejection port, and the ejection port is aligned with the...

Embodiment 2

[0028] This embodiment provides a working method of an array jet water purifier, comprising the following steps:

[0029] 1. The plasma power supply supplies power to the high-voltage electrode, and forms an electric field in the space between the high-voltage electrode and the ground electrode;

[0030] 2. The valve opening electronic controller controls the gas flow control valve to open, and the high-pressure gas in the high-pressure gas cylinder enters the electric field space to form a plasma jet and eject it. A plurality of circumferentially distributed plasma jet exciters are arranged on each layer, so that the distribution area of the ejected unbalanced plasma jet is relatively large, and the liquid spray atomized by the liquid atomizer can be completely covered. Multiple layers of circumferentially distributed plasma jet actuators are provided to make the treatment more adequate.

[0031] 3. The valve opening electronic controller controls the opening of the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com