A filter material for deep purification of drinking water

A deep purification, drinking water technology, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow water output, secondary pollution, filter element pollutants, etc., and achieves broad application prospects, uniform flow rate, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

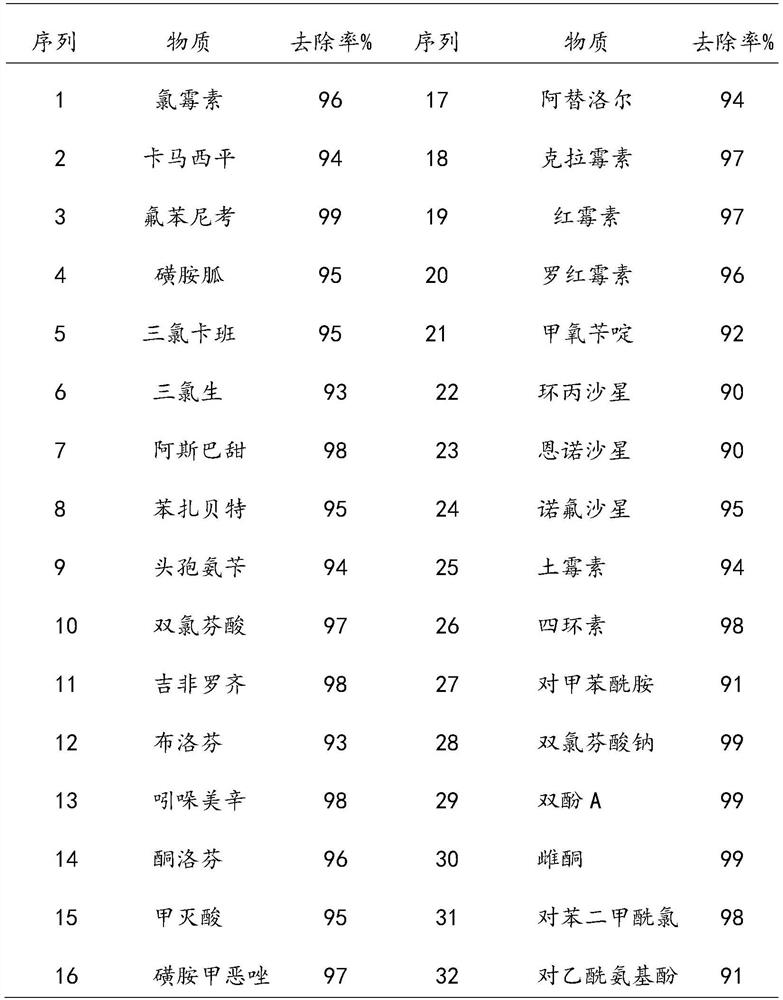

[0028] A filter material for deep purification of drinking water, which is cylindrical in shape, the diameter of the support plate is equal to the diameter of the filter material shell, the upper sieve plate and the lower sieve plate are made of polyurethane, the pore diameter is 10μm, and the thickness of the upper sieve plate is 1cm , the thickness of the lower sieve plate is 1.5cm, and the filling thickness of the amphiphilic polymer adsorption material is 5cm. The water to be purified evenly flows into the amphiphilic polymer material through the upper support plate, fully contacts with it, and eliminates new pollution such as antibiotics. The substance is fully adsorbed and removed, and the purified water is directly transported to the water inlet through the lower support plate. The preparation method of the amphiphilic polymer adsorption material is as follows:

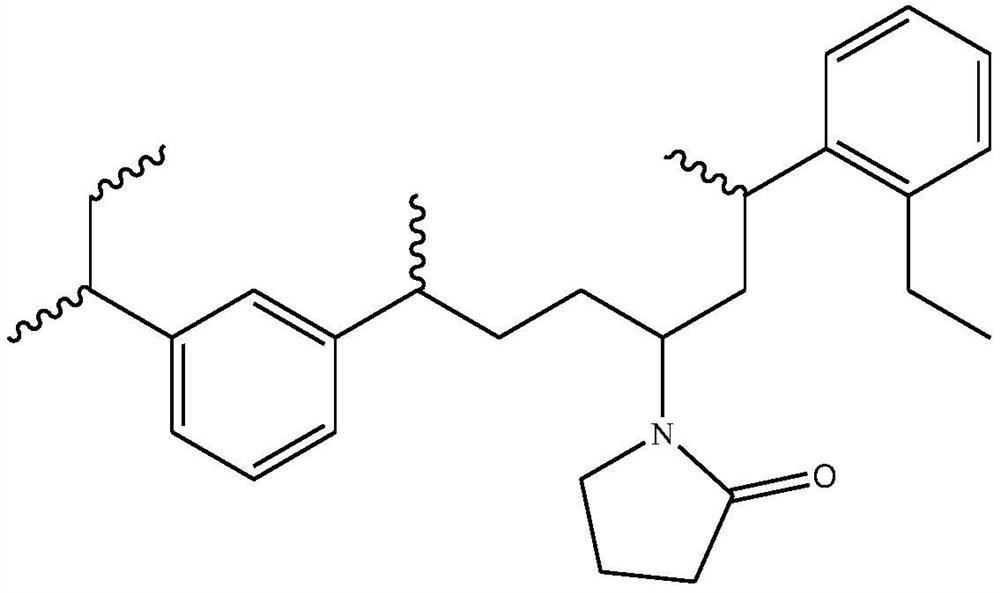

[0029] (1) Preparation of oil phase: Add 2.5g of divinylbenzene, 1g of vinylethylbenzene, and 2.5g of N-vinyl...

Embodiment 2

[0033] A filter material for deep purification of drinking water. It is cylindrical. The diameter of the support plate is equal to the diameter of the filter material shell. The upper sieve plate and the lower sieve plate are both made of polypropylene. 0.5cm, the thickness of the lower sieve plate is 1.5cm, and the filling thickness of the amphiphilic polymer adsorption material is 8cm. The new pollutants are fully adsorbed and removed, and the purified water is directly transported to the water inlet through the lower support plate. The preparation method of the amphiphilic polymer adsorption material is as follows:

[0034] (1) Prepare the oil phase: add 4.7g divinylbenzene, 2g vinylethylbenzene, and 5.1g N-vinylpyrrolidone to 6ml xylene solution containing 0.03g dibenzoyl peroxide, mix well in an ice bath, and A first oil phase, a second oil phase and a third oil phase are obtained.

[0035] (2) Preparation of water phase: Add 0.3 g of emulsifier sodium stearate and 1.0 g...

Embodiment 3

[0038]A filter material for deep purification of drinking water. It is cylindrical. The diameter of the support plate is equal to the diameter of the filter material shell. The upper sieve plate and the lower sieve plate are both made of polypropylene. 0.5cm, the thickness of the lower sieve plate is 2cm, and the filling thickness of the amphiphilic polymer adsorption material is 10cm. Pollutants are fully adsorbed and removed, and the purified water is directly transported to the water inlet through the lower support plate. The preparation method of the amphiphilic polymer adsorption material is as follows:

[0039] (1) Preparation of oil phase: 12.4g of divinylbenzene, 3g of vinylethylbenzene, and 41.5g of N-vinylpyrrolidone were added to 10ml of n-butanol solution containing 0.35g of dimethyl azobisisobutyrate, and placed in an ice bath Mix evenly to obtain the first oil phase, the second oil phase and the third oil phase respectively.

[0040] (2) Preparation of the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com