Method for recycling waste heat and dust of metallic copper smelting flue gas

A technology for the recovery of waste heat and dust from flue gas, which is applied in waste heat treatment, lighting and heating equipment, and the improvement of process efficiency. , The effect of large elastic modulus and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for recycling metal copper smelting flue gas waste heat and dust of the present invention

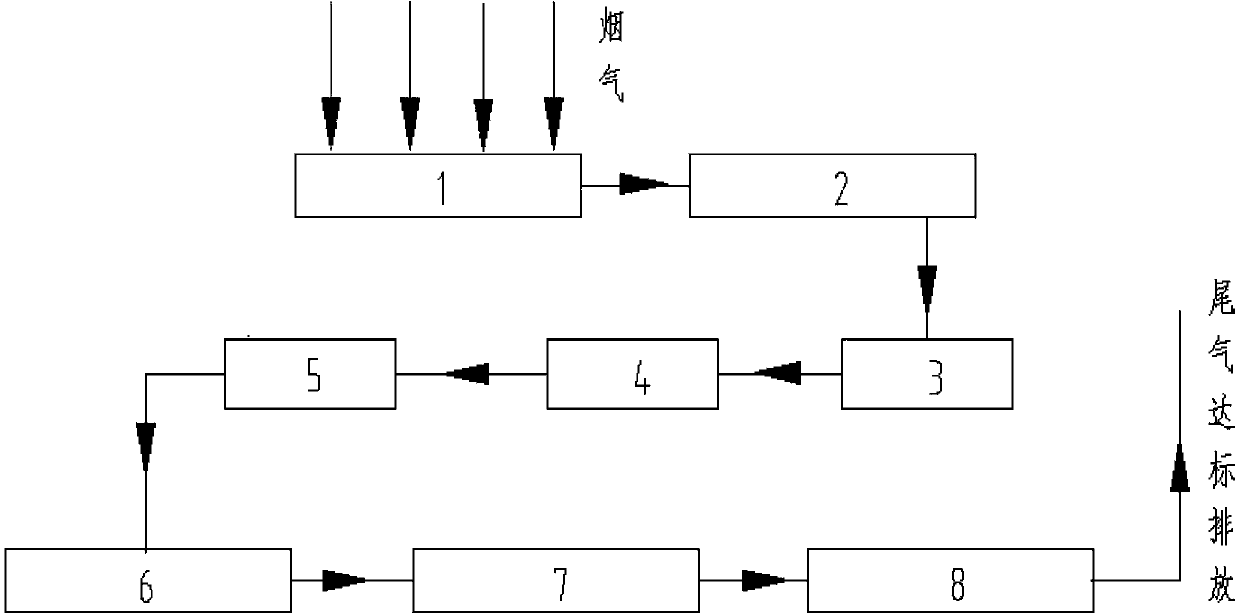

[0064] It includes a waste heat recovery device and a dust recovery device, which are characterized in that the waste heat recovery device and the dust recovery device are composed of a countercurrent heat exchange waste heat boiler A1, a silicon nitride porous ceramic filter 2, a countercurrent heat exchange waste heat boiler B3, and a countercurrent heat exchange waste heat boiler Working fluid preheater 4, plate channel gas countercurrent heat exchanger 5, bag filter dust collector 6, induced draft fan 7 are connected through pipelines or pipe fittings, flue gas desulfurization workshop 8 desulfurization after recovery of waste heat and dust After treatment, the tail gas is discharged up to standard;

[0065] Described recycling method comprises the steps:

[0066] ①. Primary recovery of waste heat

[0067] The 1400°C flue gas from the copper refining furnace enters...

Embodiment 2

[0082] A method for recycling metal copper smelting flue gas waste heat and dust of the present invention

[0083] According to the method and step of embodiment 1, difference is:

[0084] ①. Flue gas temperature 1350℃

[0085] ②The heat exchange between the flue gas and the boiler working fluid of the waste heat recovery device used in steps ①, ③, and ④ is uniform for the countercurrent heat exchange waste heat boiler A1, the countercurrent heat exchange waste heat boiler B3, and the countercurrent heat exchange waste heat boiler working fluid preheater 4. The three-pipe countercurrent heat exchange method is adopted. The heat exchange device is composed of three straight tubes with different diameters. The flue gas goes through the central tube and the outer ring gap, and the waste heat recovery working fluid goes through the inner ring gap tube. The two flow directions are opposite. Realize countercurrent heat exchange.

[0086] The recovery rate of heat carried in the fl...

Embodiment 3

[0088] A method for recycling metal copper smelting flue gas waste heat and dust of the present invention

[0089] According to the method and steps of Example 1, the difference is that: the heat exchange between the flue gas of the countercurrent heat exchange waste heat boiler A1 and the boiler waste heat recovery working fluid adopts a double-pipe countercurrent heat exchange method;

[0090] ①. Flue gas temperature 1400℃

[0091] ②. The heat exchange between the flue gas of the countercurrent heat exchange waste heat boiler B3 and the working medium preheater 4 of the countercurrent heat exchange waste heat boiler and the boiler working medium adopts the three-tube countercurrent heat exchange method.

[0092] The recovery rate of heat carried in the flue gas is ≥96%, and the recovery rate of smoke and dust is ≥98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com