Carbon gas and liquid joint production device using biomass pyrolysis and gasifying for teaching or scientific study

A technology of biomass pyrolysis and charcoal gas, which is applied in the fields of biofuel, manufacture of combustible gas, special form of dry distillation, etc., can solve the difficulties of in-depth research and development of biomass gasification technology, the inconvenience of biomass technology teaching and experimentation, and the lack of gasification and purification equipment to achieve the effect of complete separation, complete purification and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

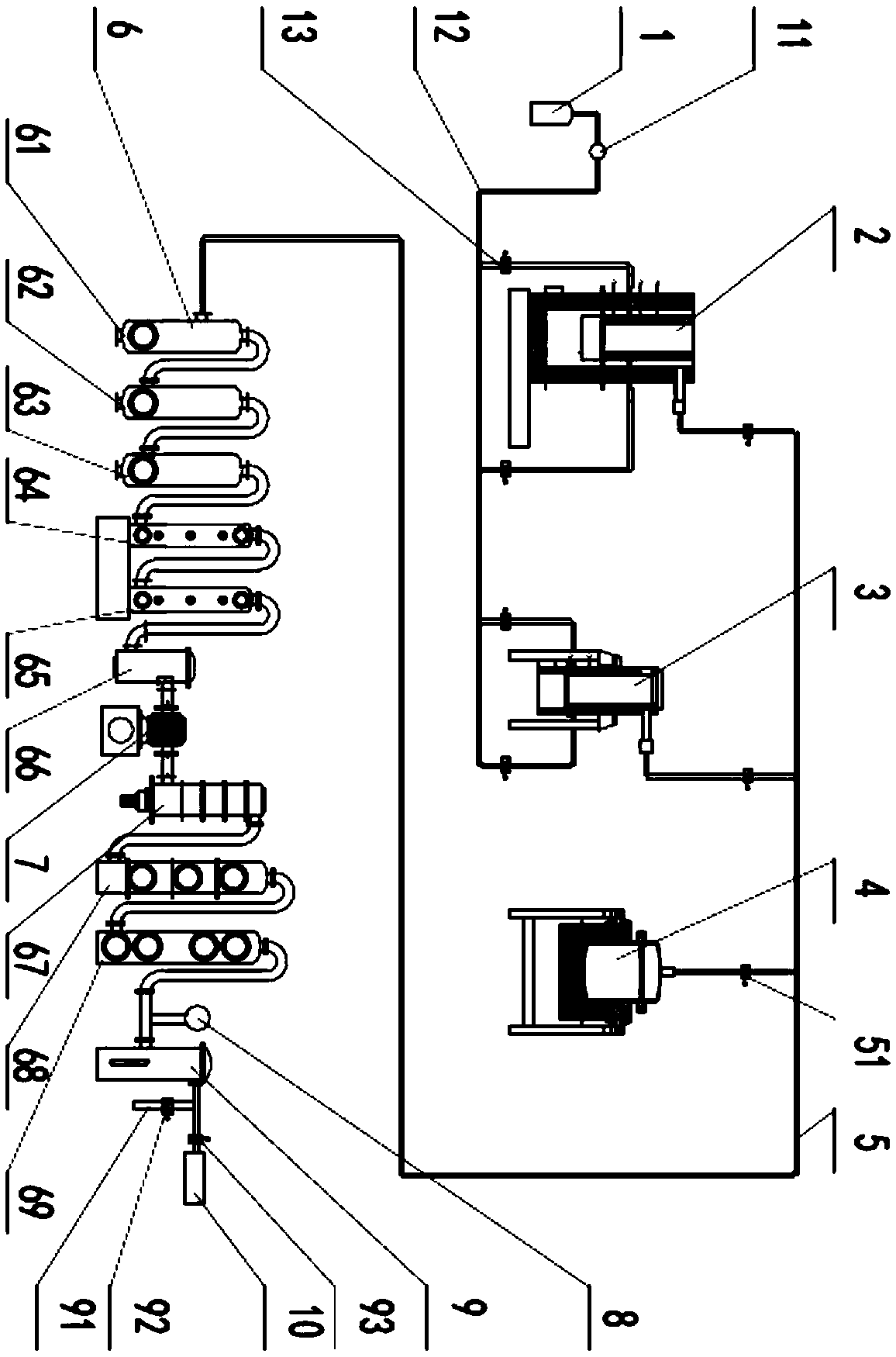

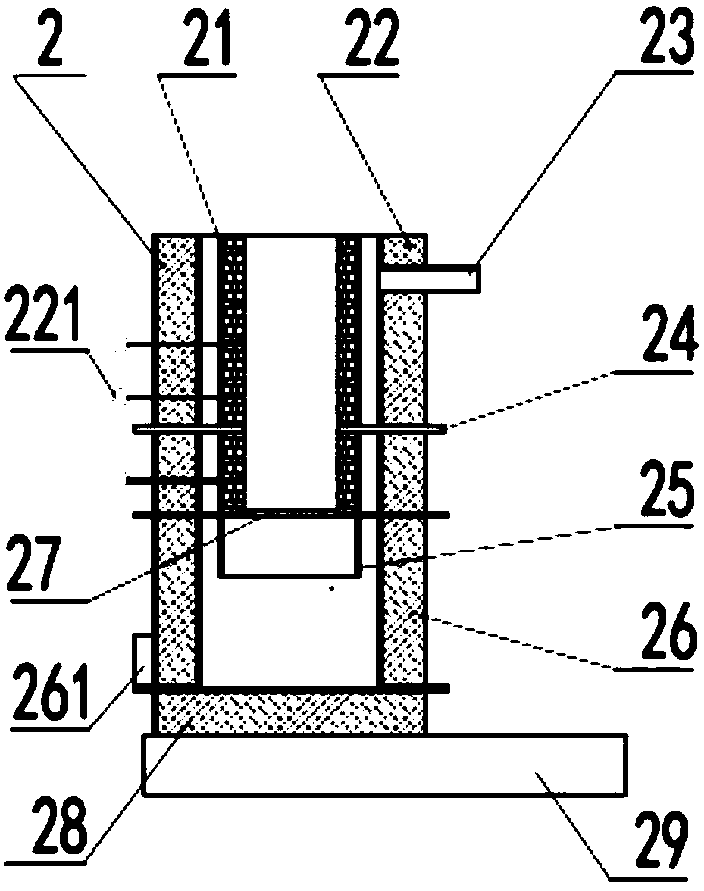

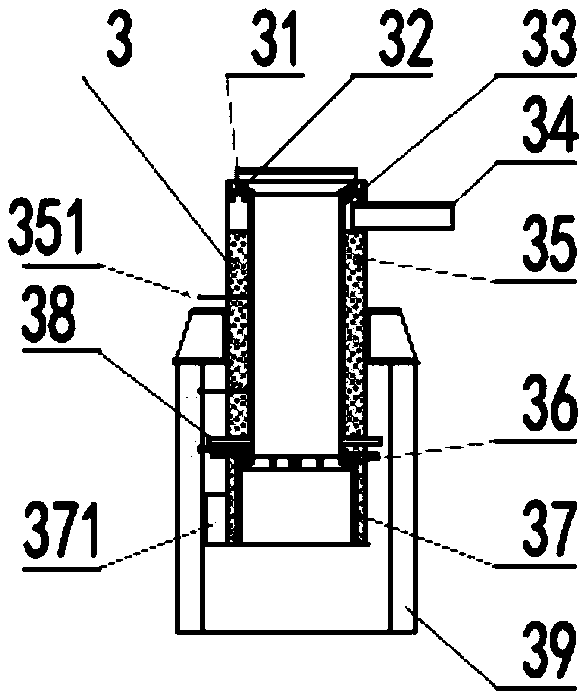

[0029] see figure 1 , a carbon-gas-liquid cogeneration device for biomass pyrolysis and gasification used for teaching or scientific research, including a biomass gasification stove and a purification system for purifying gas 6 . The biomass gasification furnace includes a steam generator 1 , a downdraft gasifier 2 , an updraft gasifier 3 , a dry distillation furnace 4 and a gas pipeline 5 . The steam generator 1 is respectively connected to the downdraft gasifier 2 and the updraft gasifier 3 through a steam pipeline 12 , and a blower 11 and several steam control valves 13 are arranged on the steam pipeline 12 . The purification system 6 includes three condensing towers, two water washing and humidifying towers, one settling tank and three detarring towers connected in series through the gas pipeline 5 .

[0030] The three condensing towers are respectively a primary condensing tower 61, a secondary condensing tower 62 and a tertiary condensing tower 63. The internal structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com