Medical wastewater treatment method

A wastewater treatment and plasma technology, applied in the field of medical wastewater treatment, can solve the problems of slow non-equilibrium plasma purification rate, failed electrodes, corrosion, etc., and achieve the effects of low pathogen regeneration rate, low use cost, and improved purification flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a medical wastewater treatment method, which specifically includes the following steps:

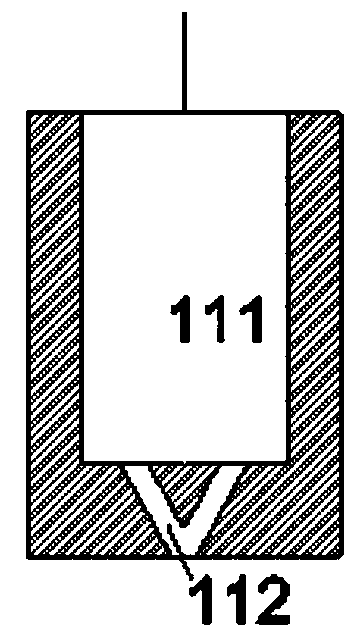

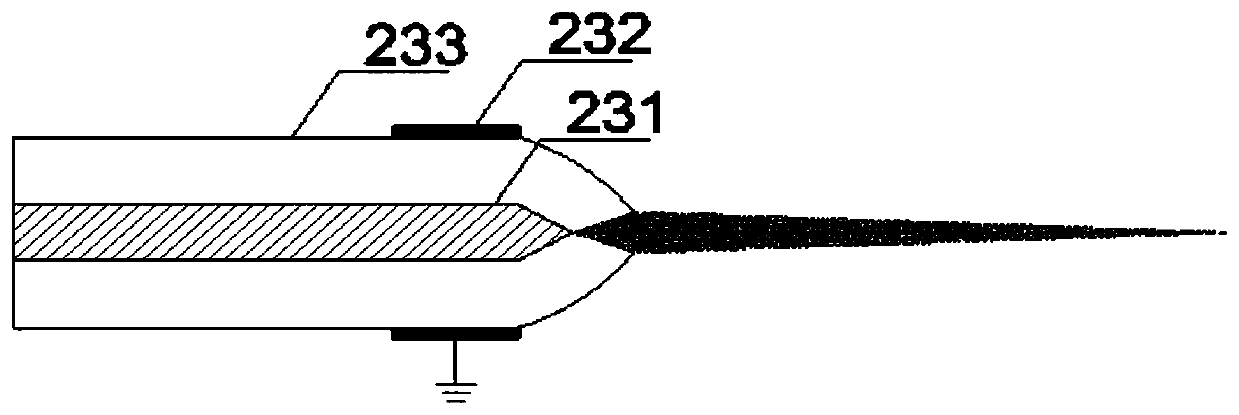

[0033] S1. A multi-layer unbalanced plasma jet exciter is arranged on the body of the jet purifier, and a plurality of unbalanced plasma jet exciters placed on each layer are distributed in a circle; the unbalanced plasma jet exciter includes a high-voltage electrode, grounding An electrode and an exciter body, the high-voltage electrode is located in the exciter body, and a ground electrode is connected to the outer wall of the exciter body;

[0034] S2. The plasma power supply supplies power to each high-voltage electrode, and forms an electric field in the space between the corresponding high-voltage electrode and the ground electrode to discharge;

[0035] S3. The valve opening electronic controller controls the gas flow control valve a and the gas flow control valve b to open, and the high-pressure gas in the high-pressure gas cylinder enters the corre...

Embodiment 2

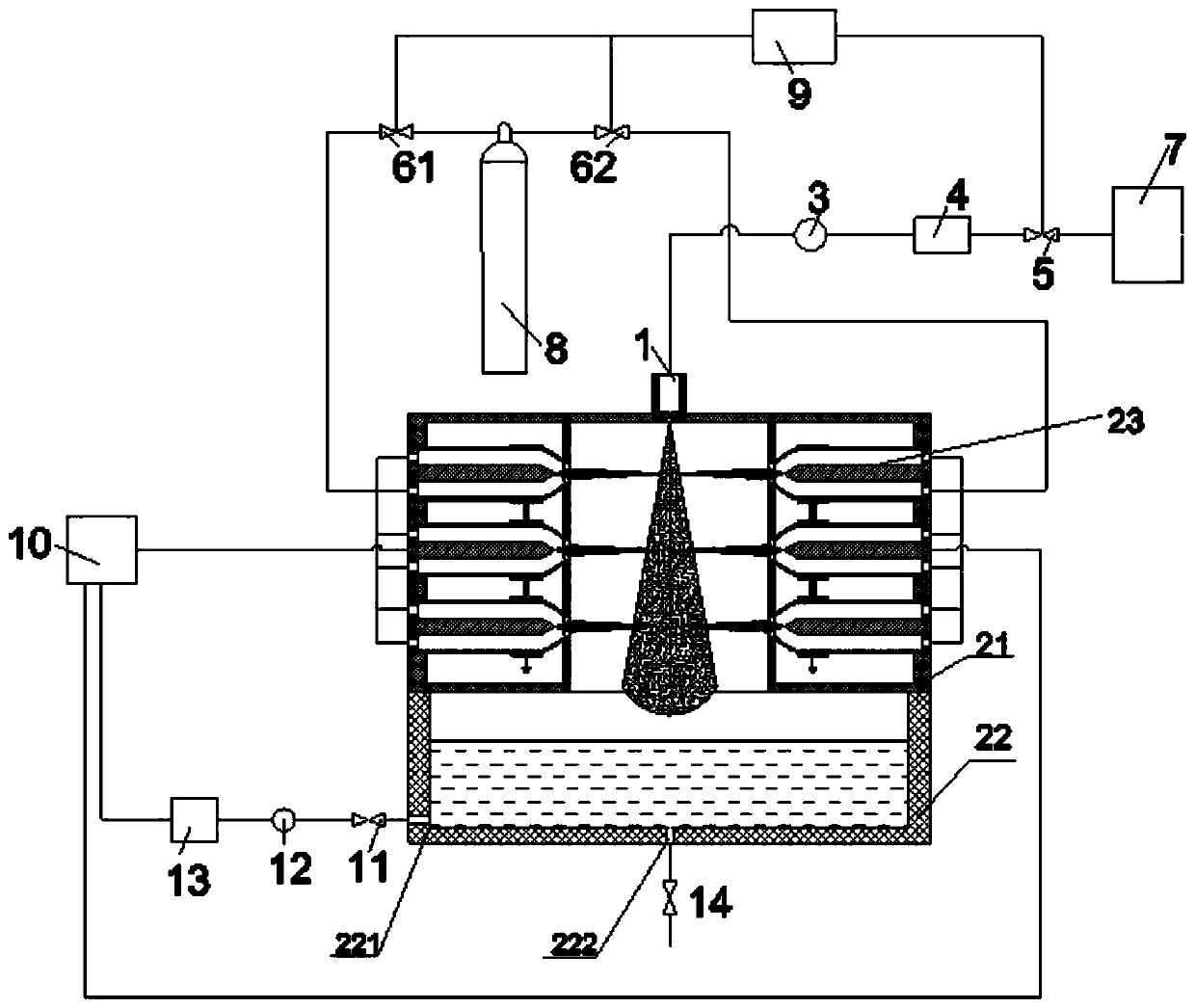

[0044] This embodiment provides a medical wastewater treatment device, including: a liquid processor, an array type unbalanced plasma jet purifier, a liquid flow meter to be purified, a filter, a liquid flow control valve, a gas flow control valve a, a gas flow control Valve b, liquid storage tank, high-pressure gas cylinder, valve opening electronic controller, plasma power supply, detection port control valve, detection port return pump, detection unit and water treatment box; the array type unbalanced plasma jet purifier It includes a jet purifier body, on which a multi-layer unbalanced plasma jet actuator is arranged, and a plurality of unbalanced plasma jet exciters arranged on each layer are distributed in a circle; the liquid processor passes through the to-be-purified The liquid flow meter, filter, and liquid flow control valve are connected to the liquid storage tank, and the liquid flow control valve is also connected to one end of the valve opening electronic control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com